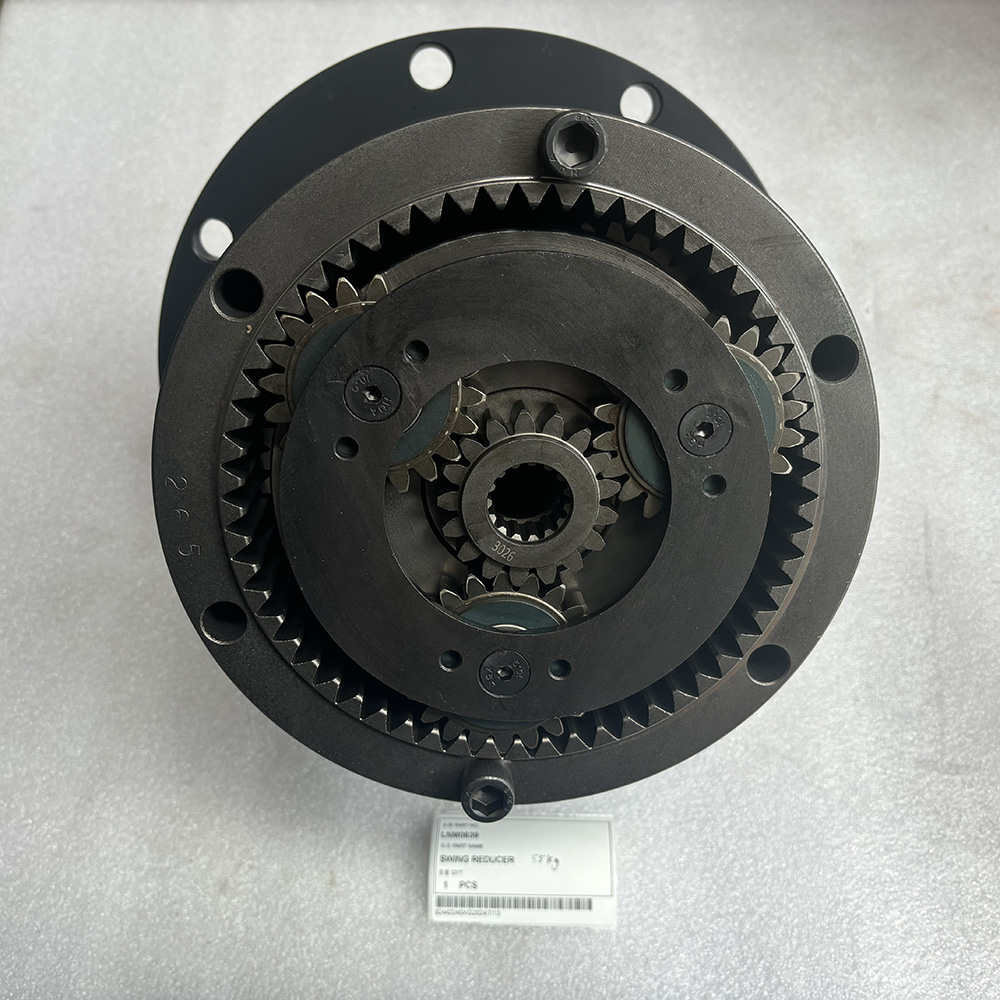

SPARKLING JCB Swing Reducer – Reliable Excavator Component

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

SPARKLING JCB Swing Reducer: Precision and Reliability You Can Trust

SPARKLING MACHINERY, established in 2013, proudly presents the JCB Swing Reducer – a vital component engineered for peak performance and durability in excavator operations. Designed with meticulous precision, the SPARKLING JCB Swing Reducer ensures smooth rotational motion and enhanced control for your JCB excavators, delivering exceptional stability and reduced wear over prolonged use.

Our swing reducers undergo rigorous manufacturing standards and stringent quality control processes, guaranteeing consistent reliability even in the most demanding working environments. Crafted from High Quality materials and compatible with JCB models, this product upholds SPARKLING’s commitment to stability, precision, and perseverance.

As part of SPARKLING MACHINERY’s comprehensive excavator parts portfolio, including hydraulic, undercarriage, engine, electrical components, and more, the JCB Swing Reducer benefits from our innovative engineering and competitive pricing strategies. We offer personalized solutions backed by expert technical support and ongoing service to minimize downtime and maximize your equipment’s operational efficiency.

Choose SPARKLING’s JCB Swing Reducer for peace of mind, unmatched quality, and a trusted partnership that helps lower your maintenance costs. With a global network and deep industry expertise, SPARKLING MACHINERY is dedicated to being your reliable supplier of excavator parts worldwide.

Product Images

FAQ

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

If you have any questions or concern, please contact us.

JCB Swing Gearbox Assembly for JS70, PC60-7 & PC70-7 Excavators – LNM0639

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

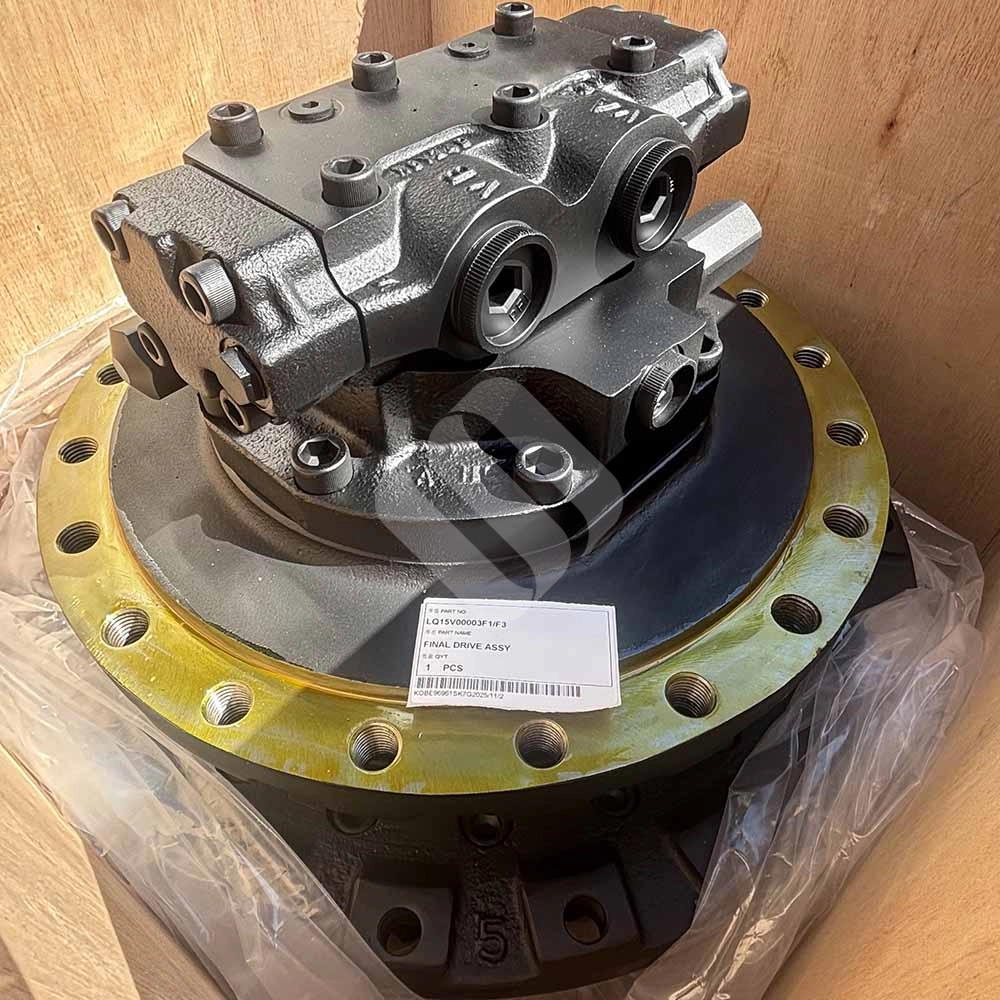

Final Drive Assy for Kobelco Excavator SK250NLC SK220LC SK250LC LQ15V00003F1 LQ15V00003F3 From SPARKLING MACHINERY

SPARKLING MACHINERY NEW SK250NLC SK220LC SK250LC LQ15V00003F1/F3 Final Drive Assy is a core power transmission component for 3 Kobelco excavator models (construction/mining use). It converts hydraulic energy to rotational force for track movement, ensuring stable traction during heavy-load tasks.

Meeting Kobelco OEM standards (dual part numbers), it resists -30°C to 100°C temps, high torque, and wear, guaranteeing seamless compatibility and long-term reliable driving performance.

Excavator Spare Parts 5V-12V DC VOE20482772 SENSOR for Volvo Construction Equipment Excavators EC160 EC160B EC180B Wheel Loaders L60E L70E L90E

The Excavator Spare Parts 5V-12V DC VOE20482772 SENSOR is a premium multi-voltage sensing component for Volvo excavators and wheel loaders. It delivers accurate operational data, adapts to dual voltage ranges, integrates seamlessly, and performs reliably in harsh construction environments.

Key Features

· Dual voltage compatibility (5V-12V DC) for versatile equipment adaptation

· Custom-engineered for Volvo EC-series excavators and L-series wheel loaders

· High-precision data detection for real-time system feedback

Vibration, dust, and extreme temperature resistant design

· Strict adherence to Volvo OEM specifications for consistent functionality

Compatible Models

· Volvo Construction Equipment Excavators: EC160, EC160B, EC180B

Volvo Construction Equipment Wheel Loaders: L60E, L70E, L90E

CA2845165 284-5165 284-5165 Hose for Caterpillar CAT 416E 422E 428E 432E 434E 442E 444E Backhoe Loaders

The SPARKLING CA2845165 hose is a High Quality 284-5165 hydraulic hose designed for Caterpillar CAT 416E, 422E, 428E, 432E, 434E, 442E, and 444E backhoe loaders. This durable 2845165 CAT hose replacement ensures reliable performance and long-lasting hydraulic system efficiency.

This part is a service component for the air cleaner group in various Caterpillar heavy machines. It is notably used in the 234-1981 Air Cleaner Group found on specific equipment series.

The CA2845165 Hose (284-5165 / 2845165) is a durable hydraulic hose designed as a dependable spare part for Caterpillar CAT backhoe loaders, including models 416E, 422E, 428E, 432E, 434E, 442E, and 444E. Manufactured to meet Caterpillar’s quality standards, this hose ensures reliable fluid transfer and sustained performance under heavy-duty operating conditions. Built for high-pressure hydraulic systems, it provides excellent resistance to abrasion, heat, and wear, making it a trusted replacement for maintenance and repair work on construction equipment.

Heavy-Duty Construction: Reinforced design offers strength and durability in high-pressure hydraulic environments.

Reliable Fluid Transfer: Ensures consistent, leak-resistant hydraulic fluid flow to maintain machine performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879