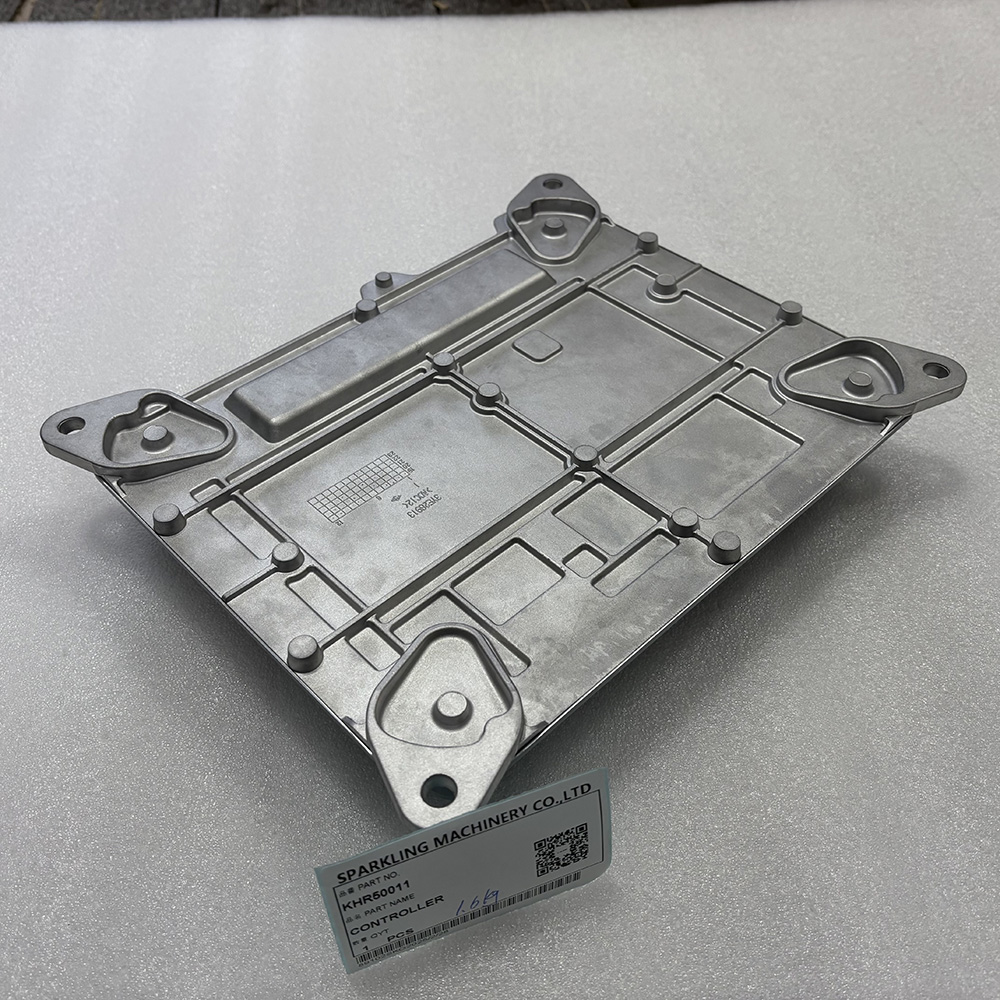

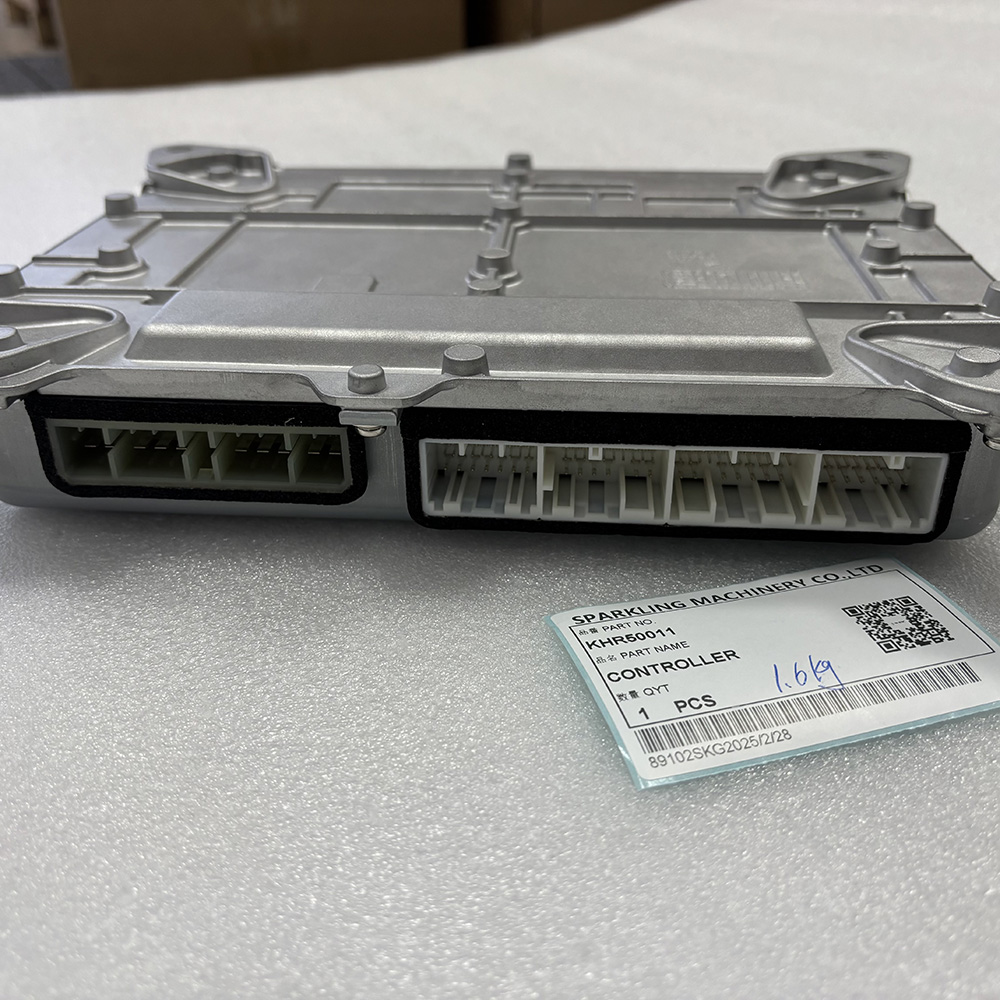

SPARKLING KHR50000 ECU – Reliable Excavator Engine Control Unit

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC.

These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site.

Engineered for OEM-level compatibility and reliability, each unit is:

-

Pre-programmed and ready for installation

Ideal for repair, replacement, or equipment upgrading, this electronic control system ensures optimal machine performance with minimal downtime.

SPARKLING KHR50000 ECU – Precision Engine Control for Peak Excavator Performance

Introducing the KHR50000 ECU by SPARKLING, a cutting-edge engine control unit designed to optimize your excavator’s efficiency, reliability, and power. As a flagship product from SPARKLING MACHINERY, a leader since 2013 in high-quality excavator parts, the KHR50000 ECU embodies our core principles of stability, precision, and perseverance.

The KHR50000 ECU is engineered for compatibility with major excavator brands like Caterpillar, Komatsu, Hitachi, and Volvo, ensuring seamless integration and superior performance across diverse machinery. This advanced ECU precisely controls engine functions, enhancing fuel efficiency and reducing emissions without compromising power output. Whether you operate under harsh conditions or demanding workloads, the KHR50000 promises durability and consistent performance.

Built with strict quality control and innovative manufacturing techniques, the SPARKLING KHR50000 ECU meets rigorous industry standards, providing a reliable solution that lowers maintenance costs and maximizes uptime. Our commitment extends beyond superior products – with tailored technical support and consultation, we help you customize and optimize your equipment for peak operation.

With SPARKLING MACHINERY’s global network, easy access to the KHR50000 ECU means faster delivery and trusted after-sales service, solidifying our position as a preferred partner in excavator parts. Choose SPARKLING KHR50000 ECU for an engineered advantage that ensures your excavator’s engine runs smarter, cleaner, and stronger.

Product Images

FAQ

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have any questions about our goods or services, please feel free to contact us.

CX130DLC CX300DLC CX490DLC CX250DLC CRAWLER EXCAVATOR KHR50000 KHR50008 KHR50009 KHR50011 KHR50013 KHR50014 KHR50015 KHR50017 ELECTRONIC CONTROL UNIT

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC. These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site. Engineered for OEM-level compatibility and reliability, each unit is: Pre-programmed and ready for installation

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW DD120B DD120C DD140C EC140D EC140E VOE11110708 FILTER RETAINER SPARKLING MACHINERY

SPARKLING MACHINERY NEW DD120B DD120C DD140C EC140D EC140E VOE11110708 Filter Retainer is a key filtration system component for 5 Volvo equipment models (construction/municipal use). It secures filters (e.g., oil, fuel filters) to prevent displacement, ensuring unobstructed impurity filtration and protecting engine/hydraulic systems.

Meeting Volvo OEM standards (VOE11110708), it resists -30°C to 85°C temps, corrosion, and vibration, guaranteeing seamless compatibility and long-term reliable filter fixation.

81N6-41050 Pin-Pivot G for Hyundai Wheel Excavators R200W-7 R200W-7A R210W-9 R210W9A

The 81N6-41050 Pin-Pivot G is a premium, heat-treated alloy steel pivot pin, the core connection component for the boom/stick articulation of Hyundai R200W-7, R200W-7A, R210W-9, R210W9A wheel excavators. It secures the boom-stick joint, withstands heavy loads and dynamic forces, and ensures smooth, precise arm movement.

Key Features

· OEM-Matched Precision: Exact diameter (80mm) and length (380mm) for Hyundai wheel excavators—no modification needed.

· High-Strength Alloy Steel: 42CrMo material with quenched-tempered treatment (HB 280–320) for ultimate tensile strength (1,000+ MPa) and wear resistance.

· Corrosion & Wear Protection: Hard chrome-plated surface (0.05–0.1mm thickness) prevents rust and reduces friction; paired with OEM-spec bushings for extended service life.

· Plug-and-Play Installation: Pre-machined chamfers and grease grooves for easy fitting; reduces replacement time to 2 hours.

Compatible Equipment

· Wheel Excavators: Hyundai R200W-7, R200W-7A, R210W-9, R210W9A, R210W-9V, R220W-9.

· Interchangeable Part Numbers: 81N6-41050, 81N641050, 81N6-41050X.

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW EW140D EW160D EW180D EW210D VOE21700315 WATER PUMP SPARKLING MACHINERY

SPARKLING MACHINERY NEW EW140D EW160D EW180D EW210D VOE21700315 Water Pump is a core cooling system component for Volvo EW140D/EW160D/EW180D/EW210D excavators (heavy-duty construction/mining use). It circulates coolant to dissipate engine heat, maintaining optimal operating temperature and preventing overheating.

Meeting Volvo OEM standards (VOE21700315), it resists -30°C to 110°C temps, corrosion, and mechanical wear, ensuring seamless compatibility and long-term reliable cooling performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879