SPARKLING KHR50011 & KHR50017 ECU – Reliable Excavator Control

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC. These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site. Engineered for OEM-level compatibility and reliability, each unit is: Pre-programmed and ready for installation

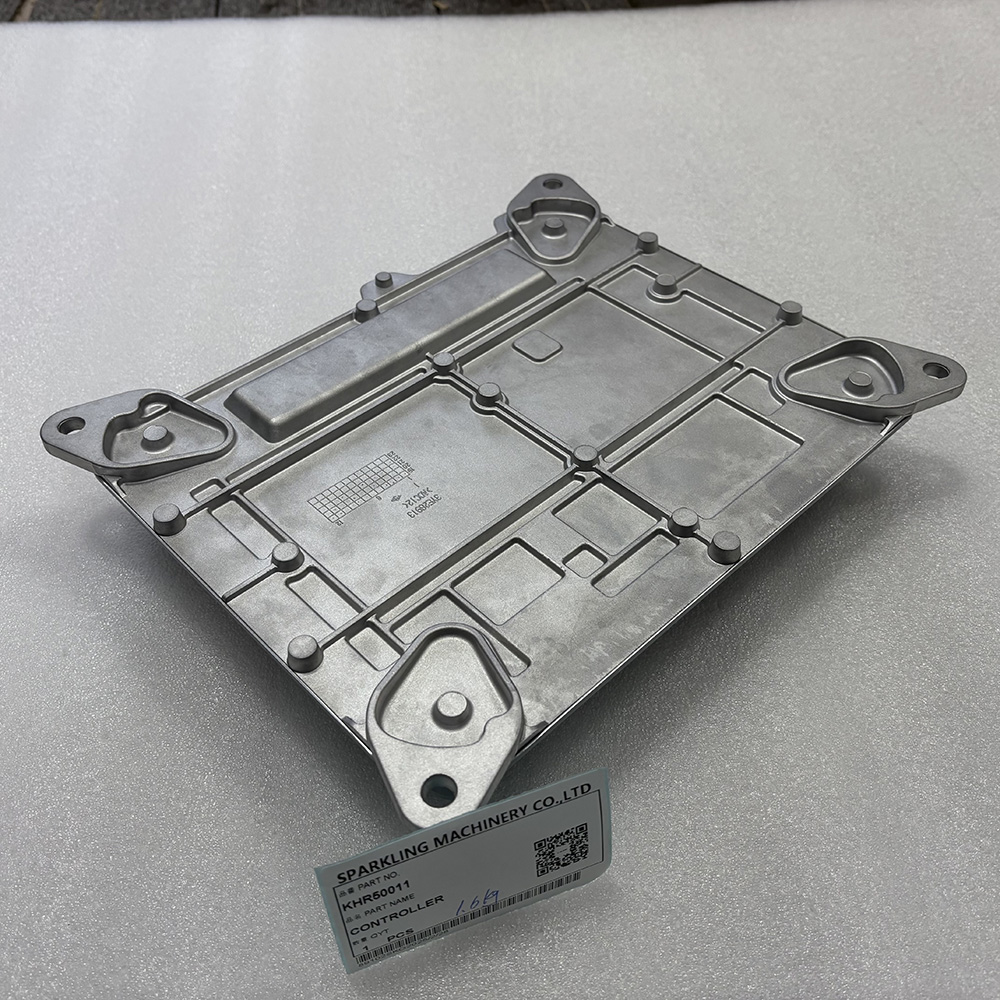

SPARKLING KHR50011 & KHR50017 ECU: Precision Control for Excavators

At SPARKLING MACHINERY, established in 2013, we prioritize stability, precision, and perseverance in producing high-quality excavator parts. The KHR50011 and KHR50017 ECU units exemplify our commitment to durable and reliable electrical components designed to enhance excavator performance. Compatible with leading brands such as Caterpillar, Komatsu, Hitachi, and Volvo, these ECUs are engineered to deliver optimal engine control and machinery responsiveness under diverse working conditions.

Each SPARKLING ECU undergoes rigorous manufacturing and quality control processes to ensure consistent operation, minimizing downtime and boosting productivity on your construction site. Our KHR50011 and KHR50017 models are built for easy integration, offering seamless electrical system management, improved fuel efficiency, and refined machine diagnostics.

We understand that every project has unique demands, which is why SPARKLING provides personalized technical support and tailored solutions to help you get the most from your equipment. Our competitive pricing does not compromise quality, reflecting our dedication to helping customers reduce operational costs while receiving dependable parts.

Choose SPARKLING's KHR50011 and KHR50017 ECU to experience advanced technology backed by thoughtful service and a global sales network. Trust in our expertise to keep your excavators running smoothly and efficiently, elevating your operation’s reliability and success.

Picture Show

Q&A

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

If you have any questions about our goods or services, please feel free to contact us.

CX130DLC CX300DLC CX490DLC CX250DLC CRAWLER EXCAVATOR KHR50000 KHR50008 KHR50009 KHR50011 KHR50013 KHR50014 KHR50015 KHR50017 ELECTRONIC CONTROL UNIT

The KHR-series Electronic Control Units (ECUs) are advanced engine and hydraulic control modules specially designed for CASE CX-series crawler excavators, including CX130DLC, CX250DLC, CX300DLC, and CX490DLC. These ECUs—part numbers KHR50000 to KHR50017—manage core operational functions such as engine response, fuel injection, hydraulic system regulation, and machine diagnostics, ensuring smooth operation, fuel efficiency, and maximum productivity on-site. Engineered for OEM-level compatibility and reliability, each unit is: Pre-programmed and ready for installation

376-9483 Control GP Handle for Caterpillar Excavators & Wheel Loaders | Fits CAT 312D2, 312D, 320D, 950K, 962K, 966K

· Function: This is an ergonomic joystick handle used to control secondary machine functions, such as auxiliary hydraulics, attachment movements (e.g., thumb or grapple), and transmission shifting.

· Design: It typically features multiple integrated thumb buttons and/or rocker switches to allow for multi-function operation without the operator releasing the joystick.

· Durability: Built to withstand heavy vibration, dust, and moisture common in construction and mining environments.

Compatible Equipment - The 376-9483 assembly is found across several Caterpillar product lines:

· Excavators: 312D2, 320D2, 323D2, 329D2, 330D2, 336D2, 349D2.

· Wheel Loaders: 950K, 962K, 966K, 972K, 980K.

· Motor Graders: 12M, 14M, 16M, 120M, 140M, 160M.

Other Specialized Equipment

· Pipelayers: PL61.

· Material Handlers: M318D MH, M322D MH, MH3049, MH3059.

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 2290 2390 2391 2491 2590 250-7700 TURBOCHARGER SPARKLING MACHINERY

SPARKLING MACHINERY NEW 2290 2390 2391 2491 2590 250-7700 Turbocharger is a core engine performance component for 5 Caterpillar equipment models (heavy-duty construction/mining use). It boosts air intake pressure to enhance combustion efficiency and amplify engine power.

Meeting Caterpillar OEM standards (250-7700), it resists up to 820°C high temps, pressure, and wear, ensuring seamless compatibility and long-term reliable engine performance.

VOE14562193 24V Excavator Switch – Compatible with Volvo EC140B EC290C EC460B EC55C EC60E

SPARKLING MACHINERY NEW EC140B EC140C EC160B EC160C EC180B EC180C VOE14562193 Switch is a dedicated, high-reliability electrical control component exclusively engineered for VOLVO EC140B/EC140C, EC160B/EC160C, and EC180B/EC180C crawler excavators—versatile mid-sized equipment widely used in construction, municipal engineering, and light mining projects. As a core interface for the excavator’s electrical system, it enables precise activation and control of key functions (e.g., auxiliary lights, hydraulic auxiliary systems, or safety alarms), ensuring responsive operation and operator safety during high-intensity tasks. This function is vital for maintaining smooth workflow coordination, preventing accidental function activation, and avoiding operational disruptions caused by faulty electrical controls during tasks like trench digging, material loading, or site grading.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14562193, the switch withstands harsh working conditions: extreme temperature fluctuations (-30°C to 70°C), water and dust ingress (IP65 protection rating), and continuous vibration from heavy-duty use. It resists electrical interference and mechanical wear, providing long-lasting control reliability for the six VOLVO crawler excavator models. Backed by strict performance verification, it guarantees seamless compatibility and safe operation for daily excavator tasks.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879