SPARKLING KOBELCO Display Unit – Precision Excavator Parts

The YY59S00009F1 Monitor Display Panel is an original OEM dashboard unit designed specifically for KOBELCO excavators SK115SR and SK135SR. It serves as the main interface between operator and machine, displaying vital operating data, including engine status, hydraulic pressure, fuel levels, and system diagnostics.

This monitor panel is built to withstand tough environments, with high-visibility LCD display, waterproof connectors, and anti-glare surface. Engineered to provide real-time machine feedback, it helps operators monitor performance and detect issues before they become failures.

Experience unmatched reliability with the SPARKLING KOBELCO display unit — engineered for precision and durability. As a cornerstone in SPARKLING MACHINERY’s extensive range of excavator parts, our KOBELCO display unit is designed to enhance the performance and stability of your excavator’s monitoring system. Founded in 2013, SPARKLING MACHINERY has dedicated itself to manufacturing high-quality components compatible with leading brands including Caterpillar, Komatsu, Hitachi, Volvo, and of course, KOBELCO.

The SPARKLING KOBELCO display unit boasts superior craftsmanship achieved through rigorous quality control and innovative engineering. This ensures seamless integration with your excavator’s existing system, providing clear, accurate readouts vital for efficient operation. Whether you’re working in extreme weather or challenging terrain, this display unit maintains optimal performance, offering steadfast support to your machine’s functionality.

Beyond quality, SPARKLING MACHINERY emphasizes personalized service. We deliver customized solutions and technical support to help you maximize productivity while minimizing downtime and costs. Our global sales network and continuous service commitment ensure that no matter where your project takes you, SPARKLING MACHINERY stands by your side.

Choose the SPARKLING KOBELCO display unit for dependable, precise monitoring — a perfect blend of skill, innovation, and value that meets the demands of modern construction and excavation. Elevate your machinery’s capabilities with SPARKLING, your trusted partner since 2013.

Picture Show

Question you may concern

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

If you have another questions, please feel free to contact us.

KOBELCO EXCAVATOR SK115SR SK135SR YY59S00009F1 MONITOR DISPLAY PANEL ORIGINAL

The YY59S00009F1 Monitor Display Panel is an original OEM dashboard unit designed specifically for KOBELCO excavators SK115SR and SK135SR. It serves as the main interface between operator and machine, displaying vital operating data, including engine status, hydraulic pressure, fuel levels, and system diagnostics.

This monitor panel is built to withstand tough environments, with high-visibility LCD display, waterproof connectors, and anti-glare surface. Engineered to provide real-time machine feedback, it helps operators monitor performance and detect issues before they become failures.

DX140W DX140W-3 DX140W-5 DX170W-5 DX190W-3 1.430-00026 1430-00026 1430-00026 GEAR SHIFT SYSTEM

The 1.430-00026 Gear Shift System is a vital transmission component designed for DOOSAN wheeled excavators, including models DX140W, DX140W-3, DX140W-5, DX170W-5, and DX190W-3. This gear shifting system ensures smooth and reliable transmission performance under various operating conditions, enabling your equipment to adapt seamlessly to job site demands.

Manufactured to meet or exceed OEM standards, this replacement unit by SPARKLING MACHINERY delivers exceptional durability, accurate shifting response, and easy installation—perfect for keeping your DOOSAN machine operating at peak performance.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC240B EC240C EC290B EC290C VOE21814758 CABLE HARNESS SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC240B EC240C EC290B EC290C VOE21814758 Cable Harness is a dedicated electrical connection component for VOLVO EC240B, EC240C, EC290B, and EC290C crawler excavators (widely used in construction, mining, and large-scale infrastructure projects). As the "electrical communication backbone" of the excavator, it transmits stable electrical signals between core components—such as ECUs, sensors, hydraulic valves, and cab instruments—to ensure smooth operation of critical functions like engine control, precision digging, and track movement during high-intensity tasks.

Meeting VOLVO OEM standards (part no. VOE21814758), it endures -30°C to 85°C temperature fluctuations, resists moisture, dust, and mechanical abrasion, and maintains reliable insulation. Strict performance testing guarantees seamless compatibility with the four VOLVO models and long-term stable signal transmission.

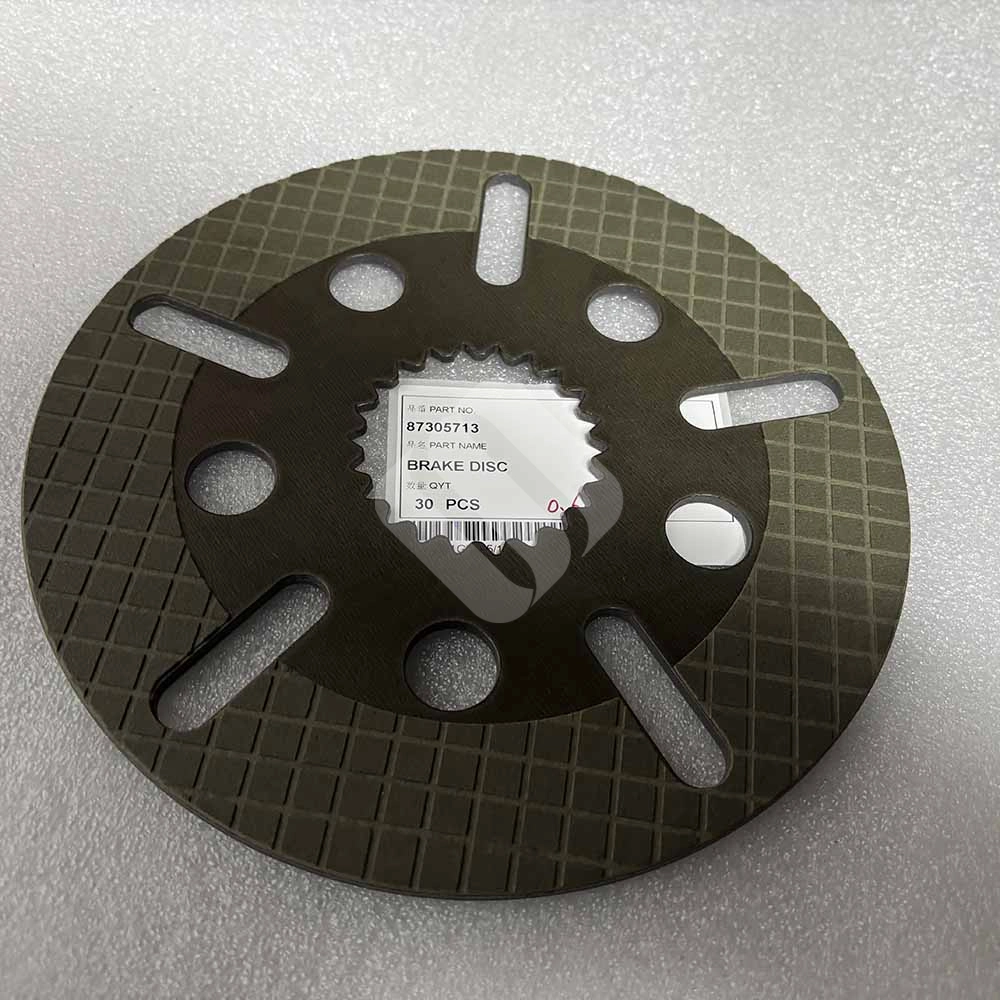

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B110B B100B LB90.B B90B B95B 87305713 BRAKE DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW B110B B100B LB90.B B90B B95B 87305713 Brake Disc is a core braking component for Volvo B110B/B100B/LB90.B/B90B/B95B excavators (heavy-duty construction/mining use). It works with brake pads to generate friction, ensuring reliable stopping and operational safety.

Meeting Volvo OEM standards (87305713), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable braking performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879