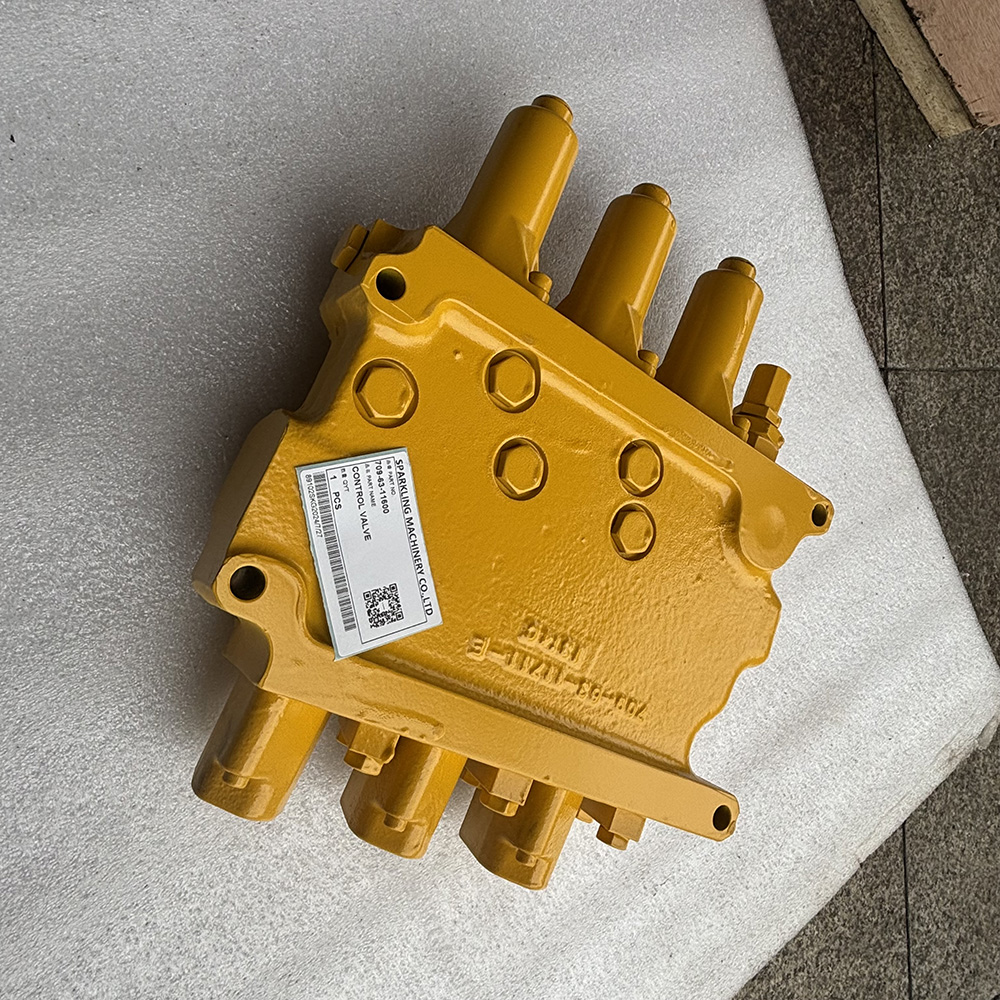

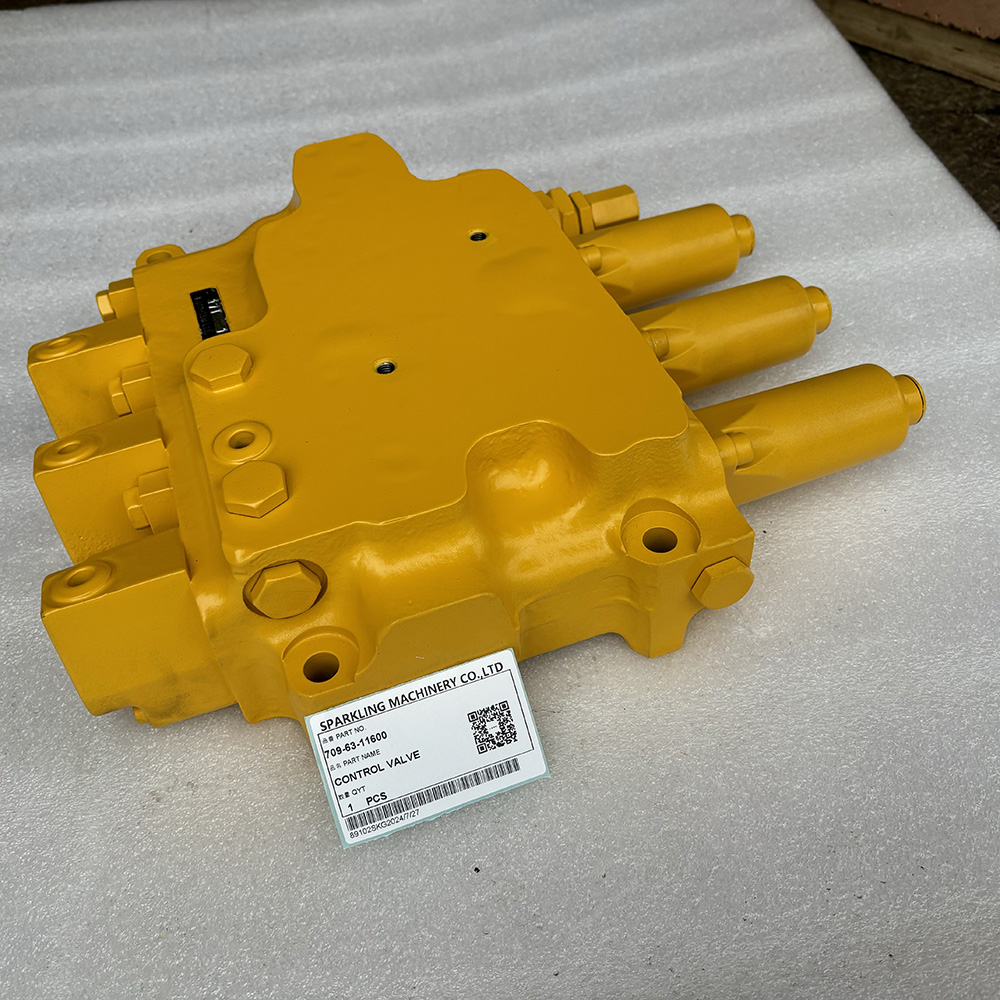

SPARKLING Komatsu D375A Control Valve – Durable & Precise

The 709-63-11501 / 709-63-11600 Control Valve Assembly is a precision-engineered hydraulic component specifically designed for Komatsu D375A series bulldozers. As a key part of the machine’s hydraulic system, this valve ensures smooth, accurate, and responsive blade and ripper control—essential for productivity in high-demand mining, earthmoving, and large-scale construction environments.

Manufactured with robust materials and OEM-level quality control, our replacement control valve delivers stable pressure regulation, excellent sealing performance, and long service life, even under continuous heavy-duty operation.

SPARKLING Komatsu D375A Control Valve – Precision and Reliability for Your Excavator

At SPARKLING MACHINERY, we understand the vital role the Komatsu D375A control valve plays in ensuring smooth and efficient hydraulic operations. Since 2013, SPARKLING has been dedicated to manufacturing high-quality excavator parts, and our Komatsu D375A control valve exemplifies our commitment to stability, precision, and durability.

Designed to meet or exceed OEM standards, the SPARKLING Komatsu D375A control valve guarantees optimal performance for your heavy machinery. Engineered with meticulous precision, it ensures reliable hydraulic flow control, enhancing the responsiveness and safety of your Komatsu D375A excavator. Whether you are operating in challenging construction sites or under demanding conditions, this control valve maintains consistent performance, reducing downtime and maintenance costs.

SPARKLING MACHINERY’s control valves undergo rigorous quality control measures to withstand the toughest environments. We offer customized solutions and technical support, ensuring that each valve matches your exact machine requirements. Our worldwide sales network and professional consultation services make it easy for you to access superior parts that protect your investment.

By choosing SPARKLING, you not only get a durable Komatsu D375A control valve but also a trusted partner dedicated to helping you maximize productivity and reduce operational costs. Experience the difference with parts engineered for excellence, backed by unparalleled service and competitive pricing.

Upgrade your Komatsu D375A excavator with the SPARKLING control valve—where innovation meets reliability.

Product Images

Frequently Asked Questions

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you have another questions, please feel free to contact us.

BULLDOZERS D375A D375A-5D S/N 17743-UP D375A-3-01 S/N 17001-UP 709-63-11501 709-63-11600 7096311600 CONTROL VALVE

The 709-63-11501 / 709-63-11600 Control Valve Assembly is a precision-engineered hydraulic component specifically designed for Komatsu D375A series bulldozers. As a key part of the machine’s hydraulic system, this valve ensures smooth, accurate, and responsive blade and ripper control—essential for productivity in high-demand mining, earthmoving, and large-scale construction environments.

Manufactured with robust materials and OEM-level quality control, our replacement control valve delivers stable pressure regulation, excellent sealing performance, and long service life, even under continuous heavy-duty operation.

12V HIGH-QUALITY 42N-64-11720 SOLENOID VALVE for Komatsu Construction Equipment PC12R PC14R PC15R PC16R PC20R PC35MR Excavator

The 12V HIGH-QUALITY 42N-64-11720 SOLENOID VALVE is a premium electro-hydraulic control component meticulously engineered for Komatsu Construction Equipment, specifically tailored to meet the precision actuation demands of PC12R, PC14R, PC15R, PC16R, PC20R, and PC35MR excavators. As a critical part of the machinery’s hydraulic control system, this 12V solenoid valve precisely regulates the flow and direction of hydraulic fluid in response to electrical signals, enabling smooth operation of key excavator functions (such as bucket movement, arm articulation, and swing control) even in demanding construction environments.

Designed to seamlessly integrate with Komatsu’s original hydraulic and electrical architectures, it delivers consistent performance that enhances machinery responsiveness, operational accuracy, and overall reliability.

Key Features

· 12V rated voltage for stable electrical compatibility with Komatsu excavator electrical systems

· Custom-engineered for perfect fit with Komatsu PC12R, PC14R, PC15R, PC16R, PC20R, PC35MR excavators

· Fast response time to electrical signals for precise, real-time hydraulic control

· Robust construction resistant to vibration, moisture, dust, and extreme temperature fluctuations

· Strict adherence to Komatsu OEM specifications for seamless integration and consistent electro-hydraulic performance

Compatible Models

· Komatsu Construction Equipment Excavators: PC12R, PC14R, PC15R, PC16R, PC20R, PC35MR

Universal Shaft Propeller Shaft 0501008339 For Hyundai and Doosan Wheel Excavator

The SPARKLING Universal Shaft Propeller Shaft 0501008339 is designed for Hyundai and Doosan wheel excavators. Engineered for durability and precision, this Hyundai Universal Shaft ensures optimal performance and longevity. Ideal replacement with reliable fit and strength.

Part number 0501008339 (also written as 0501.008.339) is a Universal Shaft (propeller shaft) manufactured by ZF for heavy equipment drivetrain systems.

Part Name: Universal Shaft / Drive Shaft.

Manufacturer: ZF (Zahnradfabrik Friedrichshafen).

Weight: Approximately 15 kg.

Alternative Name: Double Joint / Propeller Shaft.

ZF Equipment: MS-E 3050 II, MT-L 3085 II, and Starraxhse

Construction Spare Parts VOE14670742 CLUTCH for Volvo Excavators EC170D

The Construction Spare Parts VOE14670742 CLUTCH is a premium power transmission component tailored for Volvo EC170D excavators. It enables smooth power engagement/disengagement, ensures reliable torque transfer, integrates seamlessly with the equipment’s system, and maintains durability in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC170D excavators

· Smooth engagement mechanism to reduce operational shock and wear

· High torque-bearing capacity to withstand heavy-duty work demands

· Heat-resistant and wear-resistant design for long-lasting performance

· Strict adherence to Volvo OEM specifications for consistent functionality

Compatible Models

· Volvo Construction Equipment Excavators: EC170D

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879