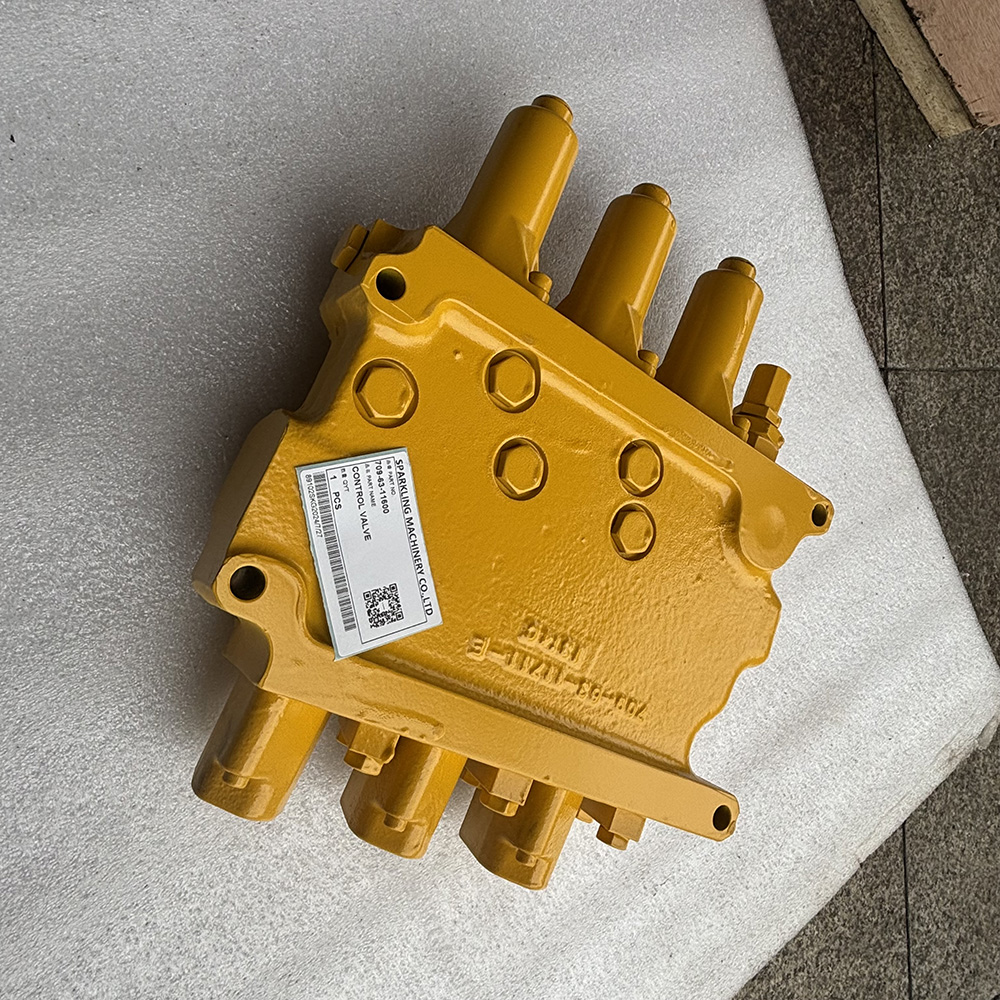

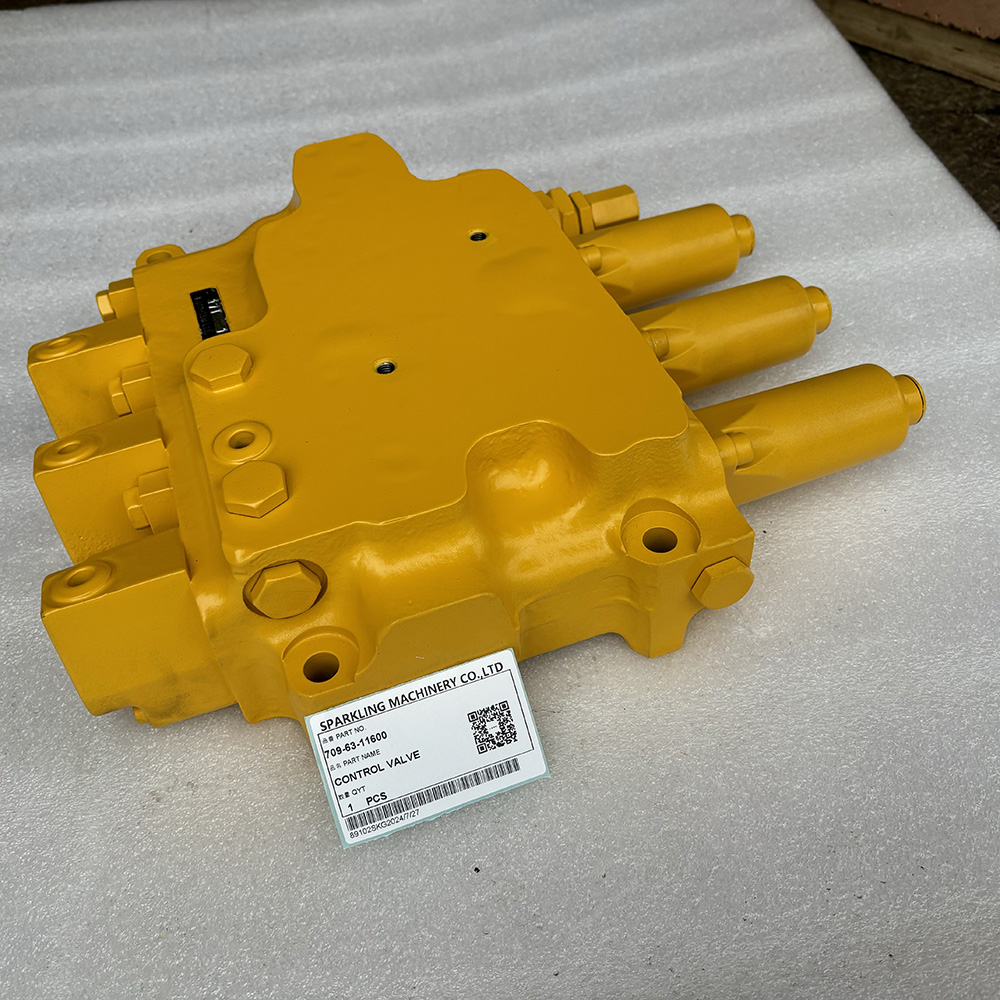

SPARKLING Komatsu Valve Replacement – Durable & Precise Parts

The 709-63-11501 / 709-63-11600 Control Valve Assembly is a precision-engineered hydraulic component specifically designed for Komatsu D375A series bulldozers. As a key part of the machine’s hydraulic system, this valve ensures smooth, accurate, and responsive blade and ripper control—essential for productivity in high-demand mining, earthmoving, and large-scale construction environments.

Manufactured with robust materials and OEM-level quality control, our replacement control valve delivers stable pressure regulation, excellent sealing performance, and long service life, even under continuous heavy-duty operation.

SPARKLING Komatsu Valve Replacement – Precision and Reliability for Your Excavator

When it comes to maintaining the optimal performance of your Komatsu excavator, choosing the right valve replacement is crucial. SPARKLING MACHINERY, established in 2013, specializes in high-quality Komatsu valve replacement parts designed to meet the highest standards of stability, precision, and durability. Our Komatsu valves undergo rigorous manufacturing and quality control processes, ensuring they perform reliably even under the most demanding operating conditions.

As part of our extensive product lineup, the Komatsu valve replacement provides seamless compatibility with your Komatsu excavator, helping to maintain hydraulic efficiency and extending the life of your machinery. Whether you operate in construction, mining, or any other heavy-duty industry, our valves deliver consistent performance to keep your equipment running smoothly.

At SPARKLING MACHINERY, we understand the practical challenges faced by operators and maintenance teams. That’s why we offer comprehensive technical support, personalized consultation, and customized solutions to meet your unique needs. Our commitment to altruism and innovation means you receive superior products at competitive prices, helping you reduce operational costs without compromising on quality.

Trusted worldwide and compatible with top brands such as Caterpillar, Hitachi, and Volvo, our products support your business goals by minimizing downtime and maximizing efficiency. Choose SPARKLING for your Komatsu valve replacement needs and experience unparalleled service, value, and reliability.

Product Image

Question you may concern

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

BULLDOZERS D375A D375A-5D S/N 17743-UP D375A-3-01 S/N 17001-UP 709-63-11501 709-63-11600 7096311600 CONTROL VALVE

The 709-63-11501 / 709-63-11600 Control Valve Assembly is a precision-engineered hydraulic component specifically designed for Komatsu D375A series bulldozers. As a key part of the machine’s hydraulic system, this valve ensures smooth, accurate, and responsive blade and ripper control—essential for productivity in high-demand mining, earthmoving, and large-scale construction environments.

Manufactured with robust materials and OEM-level quality control, our replacement control valve delivers stable pressure regulation, excellent sealing performance, and long service life, even under continuous heavy-duty operation.

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 6675-31-1011 CRANKSHAFT

SPARKLING MACHINERY NEW 6675-31-1011 Crankshaft is a critical power transmission component tailor-made for compatible heavy-duty diesel engines used in excavators, loaders, and industrial machinery. As the "rotational core" of the engine, it converts the reciprocating motion of pistons into continuous rotational torque, which drives the machinery’s hydraulic systems, undercarriage, and working mechanisms. This function is essential for delivering consistent power to support heavy-duty tasks like deep digging, large-volume material lifting, and continuous mining operations.

Designed to meet original equipment performance standards, it maintains stable operation even under extreme conditions—including high rotational speeds, intense mechanical loads, and temperature fluctuations. It ensures smooth torque transfer with minimal vibration, preventing premature wear of engine components and safeguarding long-term operational efficiency. Backed by strict performance verification, it guarantees reliable power output to minimize engine downtime and keep heavy machinery running continuously.

CATERPILLAR MADE IN CHINA SPARKLING MACHINERY NEW 324D 330D 336D 336D2 2968060 PRESSURE SENSOR

SPARKLING MACHINERY NEW 324D 330D 336D 336D2 2968060 Pressure Sensor is a dedicated precision monitoring component exclusively designed for 324D, 330D, 336D, and 336D2 excavators. As a core part of the excavators’ hydraulic and engine systems, it real-time detects critical pressure data—such as hydraulic system pressure and engine oil pressure—and transmits accurate signals to the operator’s control panel. This function is critical for preventing overpressure-related failures during heavy-duty operations like construction digging, mining loading, and infrastructure maintenance, directly ensuring stable hydraulic power output, protecting valves and pumps from pressure damage, and avoiding unplanned downtime caused by pressure anomalies.

Engineered to match original equipment performance standards, it maintains high detection accuracy even under harsh working conditions, including high oil pressure (up to 40 MPa), continuous excavator vibration, and exposure to hydraulic oil or dust. It resists signal interference and corrosion, avoiding data errors that could lead to misjudgments of the excavator’s operating status. Backed by strict performance verification, it guarantees reliable pressure monitoring to support uninterrupted operation of 324D/330D/336D/336D2 excavators.

31NB-12140 Block for Hyundai Crawler Excavators R450LC7 R450LC7A R480C9MH R480LC9

The 31NB-12140 Hydraulic Manifold Block is a precision-engineered flow control core for Hyundai R450LC7, R450LC7A, R480C9MH, R480LC9 crawler excavators. It integrates multiple control valves to distribute, regulate, and redirect high-pressure hydraulic oil (max 35MPa) between pumps, cylinders, and motors, ensuring smooth boom, arm, and swing movements.

Key Features

· OEM-Matched Precision: CNC-machined carbon steel (42CrMo) body with 6 bolt-on ports (3/4" NPT), exact mounting dimensions (320×240×180mm) for Hyundai crawler excavators—no modification needed.

· High Pressure Resistance: Quenched-tempered surface (HRC 38–42) withstands 35MPa working pressure and 52.5MPa burst pressure, preventing deformation in extreme conditions.

· Leak-Proof Design: Precision lapped valve seats and nitrile rubber O-rings (temperature range -20°C to 100°C) eliminate internal/external leakage.

· Plug-and-Play Installation: Direct bolt-on fit with pre-drilled mounting holes; reduces replacement time to 2 hours

Compatible Models: This block is used in several 7-Series and 9-Series Hyundai crawler excavators, including:

· R450LC7, R450LC7A, R500LC7, R500LC7A, RD510LC-7 (7-series)

· R480C9MH, R480LC9, R480LC9A, R480LC9S, R520LC9, R520LC9A, R520LC9S (9-series)

· Interchangeable Part Numbers: 31NB-12140, 31NB12140, 31NB-12140X.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879