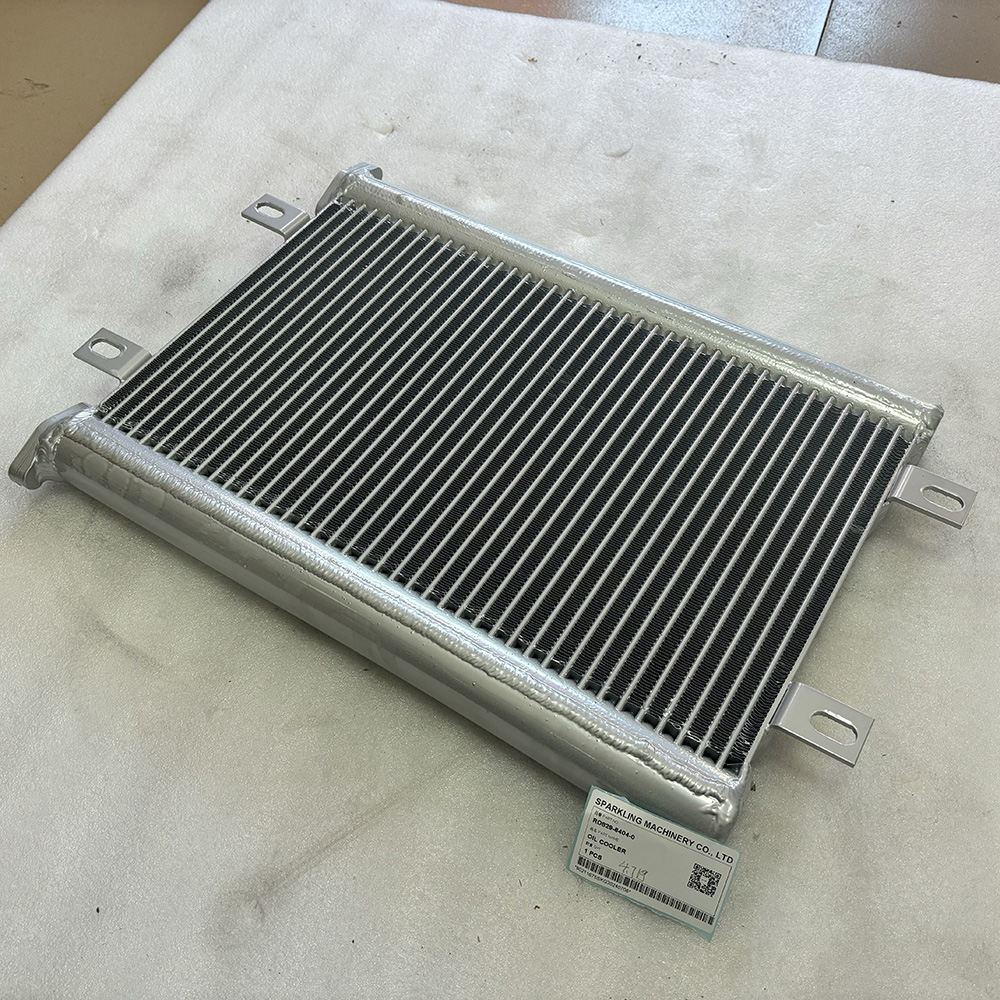

SPARKLING Kubota KX80-3 Oil Cooler – Durable & Efficient

The Kubota Oil Cooler (part nos. RD82964040, RD829‑6404‑0, KU819640) is a heavy-duty hydraulic oil radiator designed specifically for Kubota compact excavators like the KX80‑3 and KX80‑4. Featuring an OE-style plate-core design, it efficiently dissipates heat to maintain optimal hydraulic performance under continuous load. Built with OEM-grade materials and engineered for direct fitment, it ensures reliable operation and easy installation—available as genuine Kubota or high-quality aftermarket alternatives.

SPARKLING Kubota KX80-3 Oil Cooler – Reliable Cooling for Optimal Excavator Performance

The SPARKLING Kubota KX80-3 oil cooler is engineered to deliver superior cooling efficiency for your Kubota excavator, ensuring steady hydraulic oil temperature control during continuous operation. Crafted with precision and strict quality control, this oil cooler is designed to withstand harsh environments and prolonged use, providing consistent performance and extending the lifespan of your excavator’s hydraulic system.

Since 2013, SPARKLING MACHINERY has been dedicated to manufacturing high-quality excavator parts with an emphasis on stability, accuracy, and durability. Our Kubota KX80-3 oil cooler exemplifies these principles, offering compatibility with Kubota machinery while maintaining the highest standards of workmanship. Each unit undergoes rigorous testing to meet OEM specifications and guarantee unmatched reliability on the job site.

As part of our extensive product lineup, including hydraulic and engine components, undercarriage systems, and accessories for top brands like Caterpillar, Komatsu, Hitachi, and Volvo, the Kubota KX80-3 oil cooler reflects our commitment to innovation and customer satisfaction. We provide tailored solutions, technical support, and attentive after-sales services to ensure your investment delivers maximum value.

Choose SPARKLING’s Kubota KX80-3 oil cooler for a dependable, cost-effective solution to keep your hydraulic system cool and efficient, reducing maintenance downtime and supporting your workflow with peace of mind.

Product Image

Question you may concern

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

If you have any other questions, please write email to us or call us , we will reply you as soon as possible.

Kubota Oil Cooler RD82964040 / KU819640 for KX80‑3 & KX80‑4 Excavators

The Kubota Oil Cooler (part nos. RD82964040, RD829‑6404‑0, KU819640) is a heavy-duty hydraulic oil radiator designed specifically for Kubota compact excavators like the KX80‑3 and KX80‑4. Featuring an OE-style plate-core design, it efficiently dissipates heat to maintain optimal hydraulic performance under continuous load. Built with OEM-grade materials and engineered for direct fitment, it ensures reliable operation and easy installation—available as genuine Kubota or high-quality aftermarket alternatives.

HIGH-QUALITY 280-3749 GEAR INYECTION PUMP for Caterpillar Engine Equipment 303.5C, 303.5D, 303C CR, 304C CR, 304D CR Excavators

The HIGH-QUALITY 280-3749 GEAR INJECTION PUMP is a premium fuel system component meticulously engineered for Caterpillar Engine Equipment, specifically tailored to meet the precise fuel delivery demands of 303.5C, 303.5D, 303C CR, 304C CR, and 304D CR Excavators. As a core part of the machinery’s engine fuel supply system, this gear injection pump delivers a consistent, metered flow of fuel to the engine cylinders at optimal pressure, ensuring efficient combustion, stable power output, and smooth operation even during prolonged heavy-duty construction tasks.

Designed to seamlessly integrate with Caterpillar’s engine architecture, it delivers reliable performance that enhances fuel efficiency, engine responsiveness, and overall operational durability.

Key Features

· Custom-engineered for perfect compatibility with Caterpillar 303.5C, 303.5D, 303C CR, 304C CR, 304D CR Excavators

· Optimized gear design for consistent fuel pressure and precise fuel metering

· Stable operation under varying load conditions to maintain engine performance

· Enhanced sealing structure to prevent fuel leakage and ensure system integrity

· Strict adherence to Caterpillar OEM specifications for seamless integration and reliable fuel delivery

Compatible Models

· Caterpillar Engine Equipment Excavators: 303.5C, 303.5D, 303C CR, 304C CR, 304D CR

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC135B EC160C EC235D EC290C 960259 O-RING SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC135B EC160C EC235D EC290C 960259 O-Ring is a dedicated sealing component exclusively designed for VOLVO EC135B, EC160C, EC235D, and EC290C excavators—key equipment in construction, mining, and infrastructure maintenance. As a critical part of the excavators’ hydraulic, fuel, and coolant systems, it creates tight, leakproof seals between mating components (e.g., hydraulic valve connections, fuel line joints, and coolant hose interfaces). This function is essential for maintaining system pressure stability, preventing fluid leakage (hydraulic oil, fuel, coolant), and blocking dust or debris from entering internal mechanisms. It directly reduces the risk of system failures, avoids unplanned downtime, and eliminates costly repairs caused by leaks during high-intensity operations like digging, heavy material handling, or site grading.

Engineered to match VOLVO’s original equipment standards, the O-ring maintains reliable sealing performance even under harsh conditions: high pressure (up to 30 MPa), extreme temperature fluctuations (-30°C to 110°C), and continuous excavator vibration. It resists fluid aging and material degradation, ensuring long-lasting protection for the excavators’ key systems. Backed by strict performance verification, it guarantees consistent sealing support for EC135B/EC160C/EC235D/EC290C excavators.

Isuzu MADE IN CHINA SPARKLING MACHINERY NEW 8-98238255-2 EGR VALVE

SPARKLING MACHINERY NEW 8-98238255-2 EGR Valve is a premium China-made emissions control component designed for compatible diesel-powered construction machinery (such as excavators, loaders) and industrial engines. As a core part of the Exhaust Gas Recirculation (EGR) system, it precisely regulates the flow of exhaust gas back into the engine’s intake manifold—reducing the combustion temperature to minimize the formation of nitrogen oxides (NOx), a major harmful emission. This ensures compliance with global emission standards (e.g., Tier 4 Final, Euro V) while maintaining engine power output for heavy-duty tasks like digging, lifting, and material handling in construction, mining, and urban infrastructure projects.

Engineered to original equipment standards, it maintains reliable performance even under harsh working conditions, including high exhaust temperatures (up to 650°C), vibration, and exposure to soot or exhaust contaminants. With a precision-machined valve stem and adaptive sealing design, it minimizes gas leakage and ensures smooth, responsive flow control. Backed by strict quality verification, it guarantees consistent emissions reduction and prevents EGR system-related engine issues, supporting uninterrupted machinery operation.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879