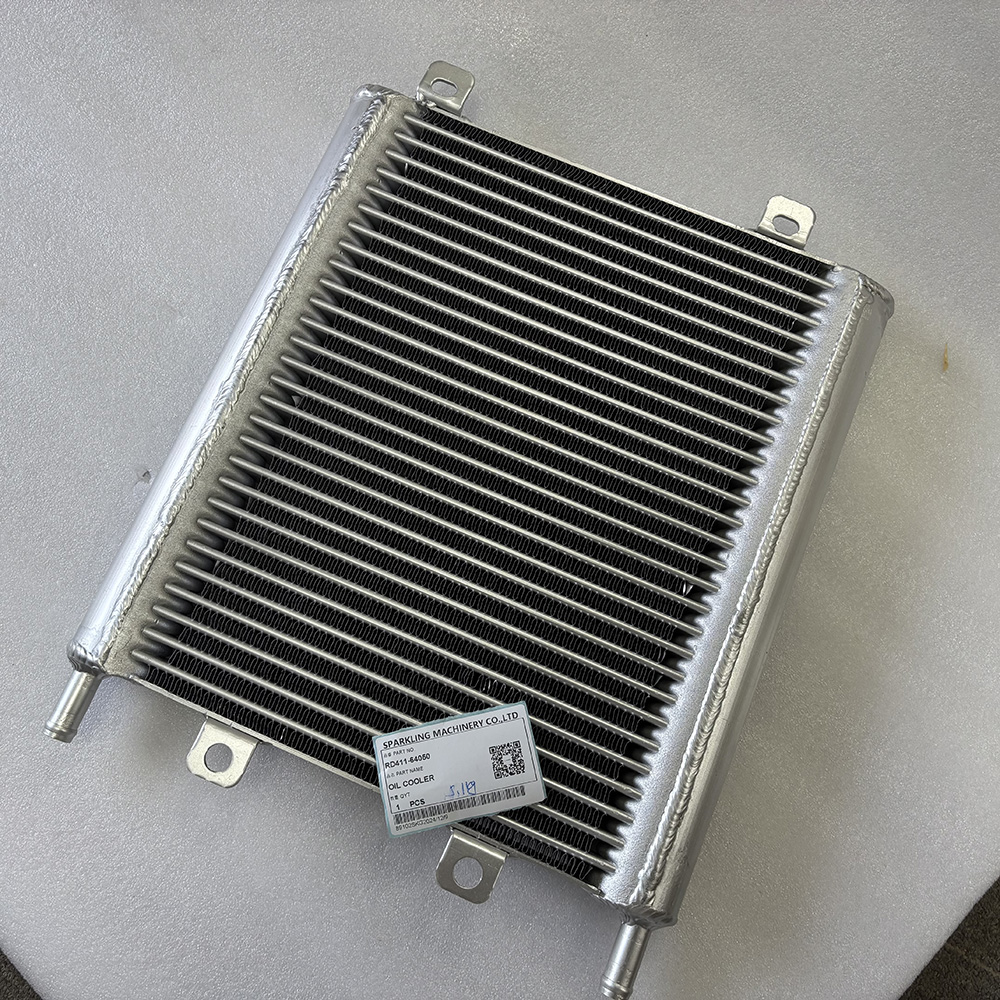

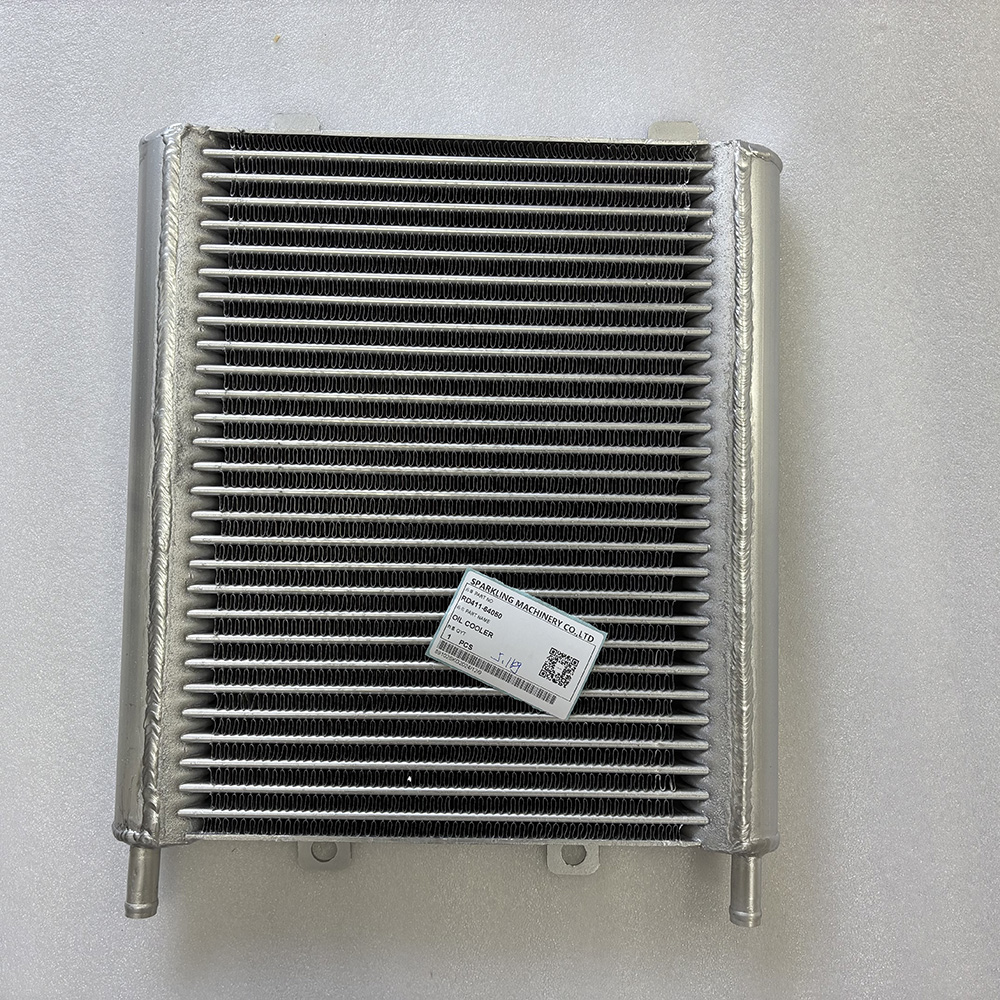

SPARKLING MACHINERY Oil Cooler – Reliable Excavator Cooling Solution

The RD411-64050 / RD411-64052 Hydraulic Oil Cooler is a premium-quality replacement part designed to fit Kubota loader backhoes and mini excavators, including models M59, KX121-3, KX161-3, and U45-3. Manufactured by SPARKLING MACHINERY, this cooler ensures optimal temperature regulation of your hydraulic system, extending the lifespan of key components and maintaining smooth machine operation.

Built with corrosion-resistant aluminum and precision-welded for strength, this oil cooler offers high heat exchange efficiency even under demanding conditions.

Discover the SPARKLING MACHINERY Oil Cooler — engineered for excellence and reliability in the toughest conditions. Since 2013, SPARKLING MACHINERY has specialized in High Quality excavator parts, delivering unbeatable stability, precision, and durability. Our oil cooler is designed to optimize hydraulic and engine performance by efficiently dissipating heat, ensuring your machinery runs cooler and lasts longer.

Compatible with leading brands like Caterpillar, Komatsu, Hitachi, and Volvo, the SPARKLING MACHINERY oil cooler undergoes rigorous manufacturing and quality control. This guarantees outstanding performance, even in demanding environments. Whether you operate mini excavators or full-scale heavy machinery, our oil cooler supports enhanced efficiency and reduces maintenance costs.

What sets SPARKLING apart is our commitment to customization and superior technical support. We collaborate closely with customers, offering tailored solutions and expert consultation to meet unique operational needs. With a global sales network and competitive pricing, SPARKLING MACHINERY not only supplies parts but also builds lasting partnerships rooted in innovation and reliability.

Invest in the SPARKLING MACHINERY oil cooler today — the smart choice for excavator professionals who demand quality and cost-effectiveness. Experience cooler operation, improved machinery lifespan, and dependable service that drives your success forward.

Picture Show

Q&A

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

LOADER BACKHOE M59 KX121-3 KX161-3 U45-3 RD411-64050 RD411-64052 HYDRAULIC OIL COOLER

The RD411-64050 / RD411-64052 Hydraulic Oil Cooler is a premium-quality replacement part designed to fit Kubota loader backhoes and mini excavators, including models M59, KX121-3, KX161-3, and U45-3. Manufactured by SPARKLING MACHINERY, this cooler ensures optimal temperature regulation of your hydraulic system, extending the lifespan of key components and maintaining smooth machine operation.

Built with corrosion-resistant aluminum and precision-welded for strength, this oil cooler offers high heat exchange efficiency even under demanding conditions.

Common Rail Injector 0445110507 129E00-53100 129E0053100 for Yanmar 4TNV88C 4TNV88C-DHKS 4TNV98C 4TNV98C-NTS 4TNV98C-NVFV

Key Features & Advantages:

Precision Fuel Delivery: Advanced high-pressure common rail (HPCR) technology ensures accurate fuel metering and timing control, leading to improved fuel economy and reduced emissions.

Engine Compatibility: Designed as a direct replacement for Yanmar engines 4TNV88C, 4TNV98C, and specific variants like 4TNV88C-DHKS, 4TNV98C-NTS, 4TNV98C-NVFV, 4TNV98C-NMS2, and 4TNV98C-SJLW5.

Durable Construction: Built with high-grade metal materials to withstand harsh operating conditions and provide long-lasting durability.

Performance Restoration: A new injector helps resolve common issues such as rough idling, loss of power, increased fuel consumption, or excessive black smoke.

Specifications:

Part Numbers: 0445110507, 129E00-53100, 129E0053100

Fuel Type: Diesel

Condition: New Aftermarket / Genuine Options Available

Caterpillar 267-1082 Pump Coupling | CA2671082 for 305C CR 305.5E Excavator | China Made

The Caterpillar Coupling-Pump (Part No. 267-1082 / CA2671082 / 2671082) is a high-quality aftermarket replacement part made in China, engineered to fit CAT mini hydraulic excavators such as 305C CR, 305.5E, and certain Caterpillar wheel loader models.

This coupling serves as a crucial link between the engine and hydraulic pump, ensuring efficient power transmission while absorbing vibration and reducing stress on connected components. Built from durable elastomeric and metal materials, it offers excellent torsional flexibility and resistance to wear — helping maintain optimal machine performance.

If you're looking for a cost-effective yet reliable alternative to OEM parts, this China-made coupling is a smart choice for equipment maintenance and repair, without compromising functional integrity.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879