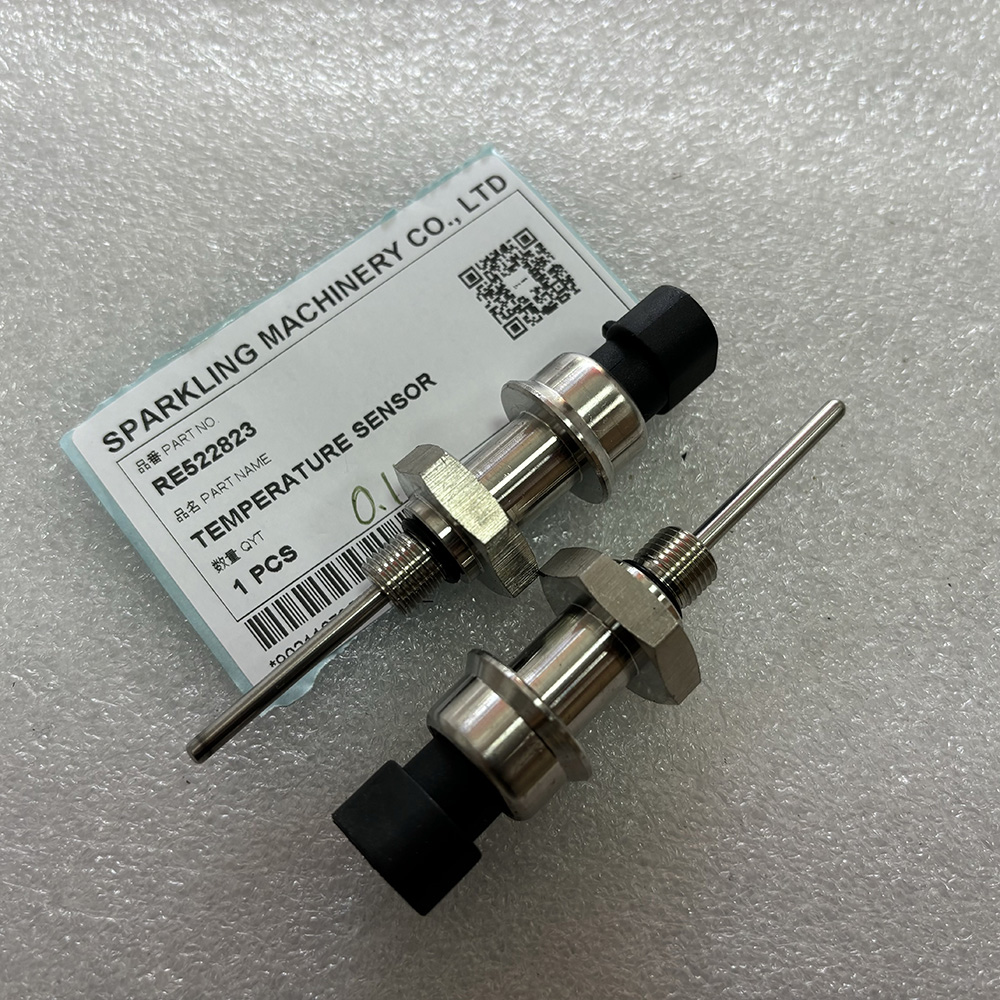

SPARKLING OEM Deere Sensor – Reliable Excavator Component

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING OEM Deere Sensor – Precision and Reliability You Can Trust

SPARKLING MACHINERY proudly presents the OEM Deere sensor, engineered to meet the highest standards of performance and durability. Since 2013, SPARKLING has been dedicated to delivering top-quality excavator parts, specializing in components that ensure stability, precision, and long-lasting operation. Our OEM Deere sensor is no exception—it is designed to provide accurate, real-time data for optimal machine performance, making it an essential component for Deere excavators and heavy machinery.

Crafted with rigorous quality control and advanced manufacturing processes, the SPARKLING OEM Deere sensor guarantees consistent reliability under diverse operating conditions. Whether for hydraulic systems, engine management, or electrical components, this sensor integrates seamlessly with Deere equipment, enhancing efficiency and reducing downtime.

As a part of our comprehensive product lineup, the OEM Deere sensor benefits from SPARKLING’s commitment to innovation and meticulous customer service. We offer tailored solutions and expert technical support, ensuring that every sensor meets your specific needs at a competitive price. Our global sales network provides fast, dependable delivery and ongoing service, making SPARKLING MACHINERY your trusted partner for excavator parts worldwide.

Choose SPARKLING OEM Deere sensor for precision, reliability, and peace of mind—engineered to keep your machinery running smoothly and efficiently.

Product Images

Question you may concern

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you have any other questions, please write email to us or call us , we will reply you ASAP.

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC140B EC160B EC180B EC460CHR 14514215 CONT VALVE

SPARKLING MACHINERY NEW EC140B EC160B EC180B EC460CHR 14514215 Cont Valve is a premium China-made hydraulic component specifically engineered for EC140B, EC160B, EC180B, and EC460CHR excavators. As a critical part of the hydraulic system, it regulates fluid flow, pressure, and direction to control the operation of actuators such as booms, arms, and buckets, ensuring precise and responsive machinery movement in construction, mining, and heavy-duty applications.

Designed to original equipment standards, it maintains stable hydraulic control and efficient energy transfer even under continuous high-pressure operation. With optimized valve spool design for minimal pressure loss, it adapts seamlessly to harsh working environments, from dusty job sites to wet conditions. Backed by strict quality verification, it guarantees consistent performance to support uninterrupted machinery operation.

HYUNDAI MADE IN CHINA SPARKLING MACHINERY NEW R210LC-9 R210NLC-9 R210W-9 11Q6-40642 R220/260LC-9S OIL COOLER

SPARKLING MACHINERY NEW 11Q6-40642 R220/260LC-9S Oil Cooler is a dedicated thermal management component exclusively designed for R220LC-9S and R260LC-9S excavators. As a core part of the excavators’ hydraulic and engine systems, it efficiently dissipates heat from hydraulic oil and engine oil—preventing oil overheating during heavy-duty operations like deep digging, high-load lifting, and continuous idling in construction, mining, or infrastructure projects. This function is critical for maintaining oil viscosity and lubrication performance, which directly protects hydraulic components (e.g., pumps, valves) and engine parts from premature wear, ensuring stable machinery power output and extending service life.

Engineered to match original equipment performance standards, it retains strong heat dissipation efficiency even under harsh working conditions, including high ambient temperatures, dust accumulation, and constant excavator vibration. It resists oil leakage and internal blockages, avoiding system failures that could lead to unplanned downtime or costly component repairs. Backed by strict performance verification, it guarantees reliable heat exchange to support uninterrupted operation of R220/260LC-9S excavators.

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 81881200/320-7346 DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW 81881200/320-7346 Disc is a core friction component for Caterpillar excavators (heavy-duty construction/mining use). It works with braking or transmission systems to generate controlled friction, ensuring reliable stopping or power transfer.

Meeting Caterpillar OEM standards (81881200/320-7346), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable friction performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879