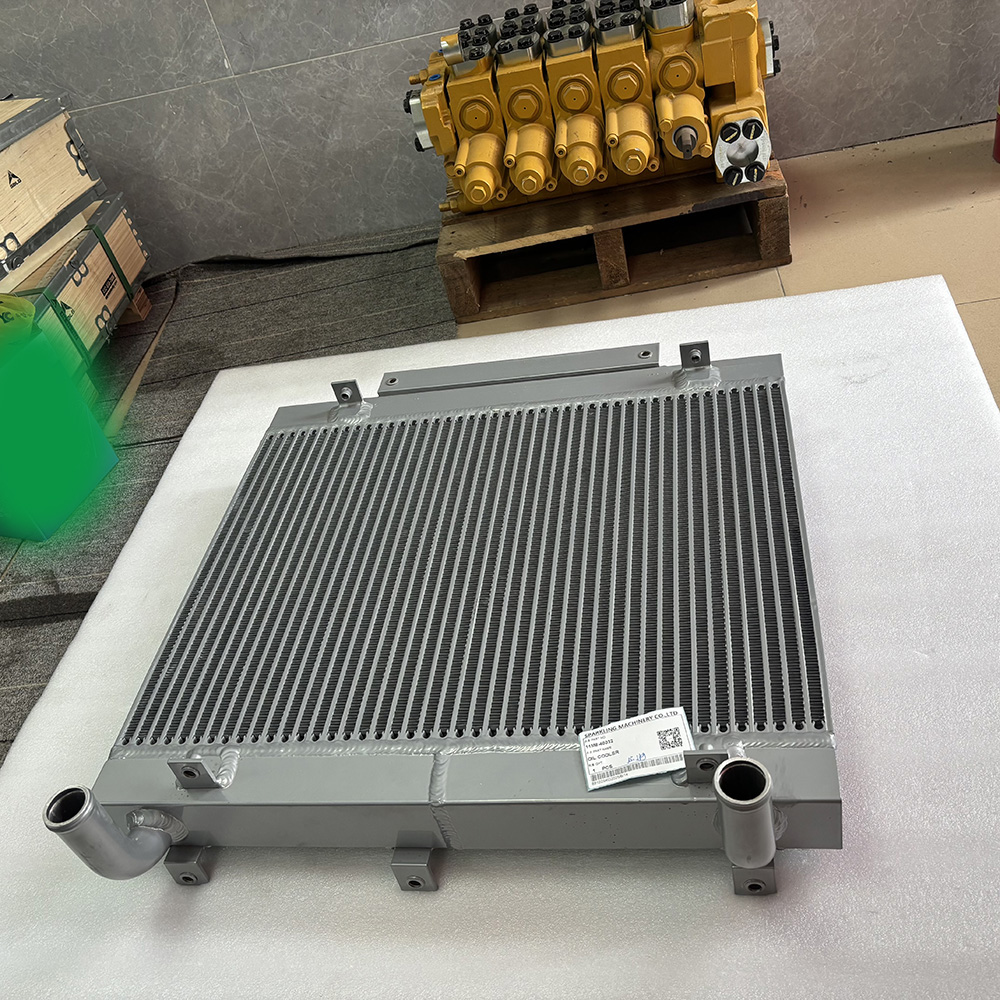

SPARKLING OEM Hyundai Oil Cooler Plate-Fin – Reliable Excavator Part

The Hydraulic Oil Cooler Assembly (part no. 11M8‑40032 / 11M8‑43120) is a high-efficiency, all‑aluminum plate‑fin heat exchanger engineered for Hyundai compact excavators—specifically R55‑7 and R55W‑7 (also fitting R60‑7). Built free of epoxy, this OEM‑spec cooler ensures optimal heat dissipation and withstands continuous high pressure (up to 2 MPa), making it a reliable drop‑in replacement for demanding operation environments

The SPARKLING OEM Hyundai Oil Cooler Plate-Fin is a critical component designed to keep your excavator’s engine running smoothly and efficiently. Manufactured with precision and high-quality materials, this oil cooler plate-fin helps regulate engine temperature by improving heat dissipation, protecting the engine from overheating and extending its lifespan.

Since 2013, SPARKLING MACHINERY has specialized in delivering durable and reliable excavator parts. We understand the demanding conditions in which excavators operate, so we ensure every oil cooler plate-fin meets strict quality control standards. Compatible with Hyundai excavators, our product guarantees a perfect fit and stable performance under various working environments—whether in construction, mining, or heavy-duty tasks.

Our oil cooler plate-fin’s plate-fin design maximizes surface area for superior cooling efficiency, reducing the risk of engine failure caused by overheating. This ensures your hydraulic systems and engine components maintain optimal temperatures, enhancing overall machinery reliability and reducing downtime.

At SPARKLING, we combine craftsmanship with innovative technology, offering not only top-tier parts but also tailored technical support. Our commitment to precision, stability, and perseverance means you receive a product that you can trust and rely on. Additionally, our competitive pricing helps you manage maintenance costs without sacrificing quality.

Choose SPARKLING OEM Hyundai Oil Cooler Plate-Fin for a practical, long-lasting solution designed to keep your excavator performing at its best. Backed by a global sales network and personalized customer care, SPARKLING MACHINERY is your dependable partner in excavator parts.

Detailed display

Q&A

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

Hyundai Oil Cooler Assy 11M8‑40032 / 11M8‑43120 for R55‑7 & R55W‑7 Excavators

The Hydraulic Oil Cooler Assembly (part no. 11M8‑40032 / 11M8‑43120) is a high-efficiency, all‑aluminum plate‑fin heat exchanger engineered for Hyundai compact excavators—specifically R55‑7 and R55W‑7 (also fitting R60‑7). Built free of epoxy, this OEM‑spec cooler ensures optimal heat dissipation and withstands continuous high pressure (up to 2 MPa), making it a reliable drop‑in replacement for demanding operation environments

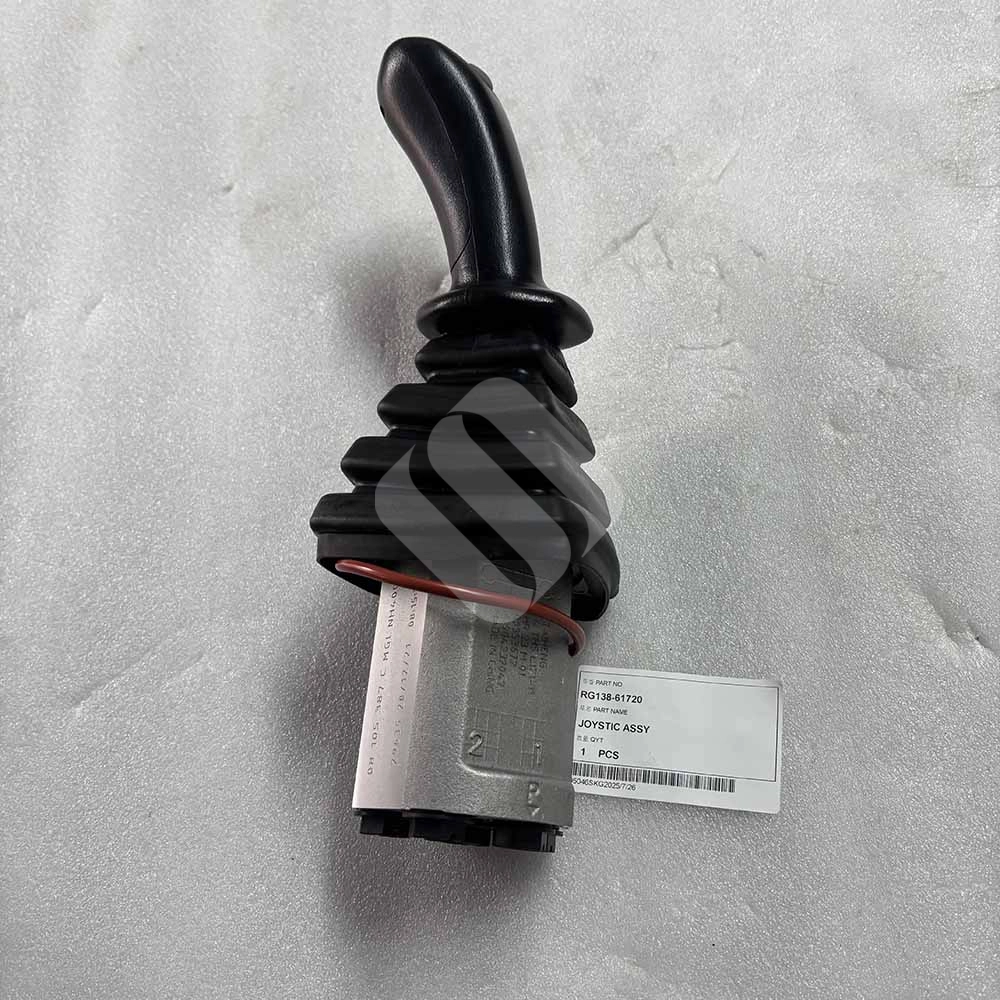

KUBOTA MADE IN CHINA SPARKLING MACHINERY NEW KX016 KX018 RG138-61720 JOYSTICK ASSY

SPARKLING MACHINERY NEW KX016 KX018 RG138-61720 Joystick Assy is a dedicated operational control component exclusively designed for KX016 and KX018 mini excavators—ideal for small-scale construction, landscaping, and indoor renovation tasks. As the core of the excavators’ human-machine interface, it enables precise control of the machine’s working mechanisms (e.g., bucket movement, arm lifting, and body rotation) by translating the operator’s manual inputs into electrical or hydraulic signals. This function is critical for ensuring smooth, accurate operation during delicate tasks like trench digging, material placement, and narrow-space maneuvering, directly enhancing work efficiency and reducing the risk of operational errors that could damage the machine or surrounding structures.

Engineered to match original equipment performance standards, it maintains responsive control and structural durability even under harsh working conditions, including continuous operator use, vibration, and exposure to dust or light moisture. It resists switch failure and handle loosening, avoiding control delays or malfunctions that lead to unplanned downtime. Backed by strict performance verification, it guarantees reliable operational control to support uninterrupted use of KX016/KX018 mini excavators.

Hydraulic Pump 31QC-10010 31QA-10021 K3V180DTP for Hyundai Excavator R420LC-9S R430LC-9SH

The 31QC-10010 and 31QA-10021 hydraulic main pump assembly is designed for Hyundai excavators R420LC-9S and R430LC-9SH. This pump is the core component of the excavator hydraulic system, responsible for supplying pressurized hydraulic oil to power the boom, arm, bucket, and other working functions. It is commonly used as a replacement for Kawasaki K3V180DTP axial piston pumps and is suitable for heavy-duty construction applications.

Technical Specifications

Part Type: Main Hydraulic Pump.

Model Identification: Specifically identified as a Kawasaki K3V180DTP-170R-9N62 or K3V180DTP series pump.

Purpose: Delivers hydraulic power for essential excavator functions, including digging, lifting, and rotating.

Compatible Equipment

This pump is a critical component for several heavy-duty Hyundai excavator models:

R430LC-9SH R420LC-9S R430LC-9

Doosan (DEUTZ) HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 160 160TC 200-V 200TC-V 0501-317-949 SPEED SENSOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW 0501-317-949 Speed Sensor is a core detection component for Doosan (DEUTZ) 160/160TC/200-V/200TC-V excavators (construction/mining use). It accurately monitors engine or hydraulic system speed, transmitting real-time data for stable operation.

Meeting Doosan (DEUTZ) OEM standards (0501-317-949), it resists -30°C to 100°C temps, vibration, and interference, ensuring seamless compatibility and reliable long-term performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879