SPARKLING OEM Swing Gear Box – Reliable Excavator Part

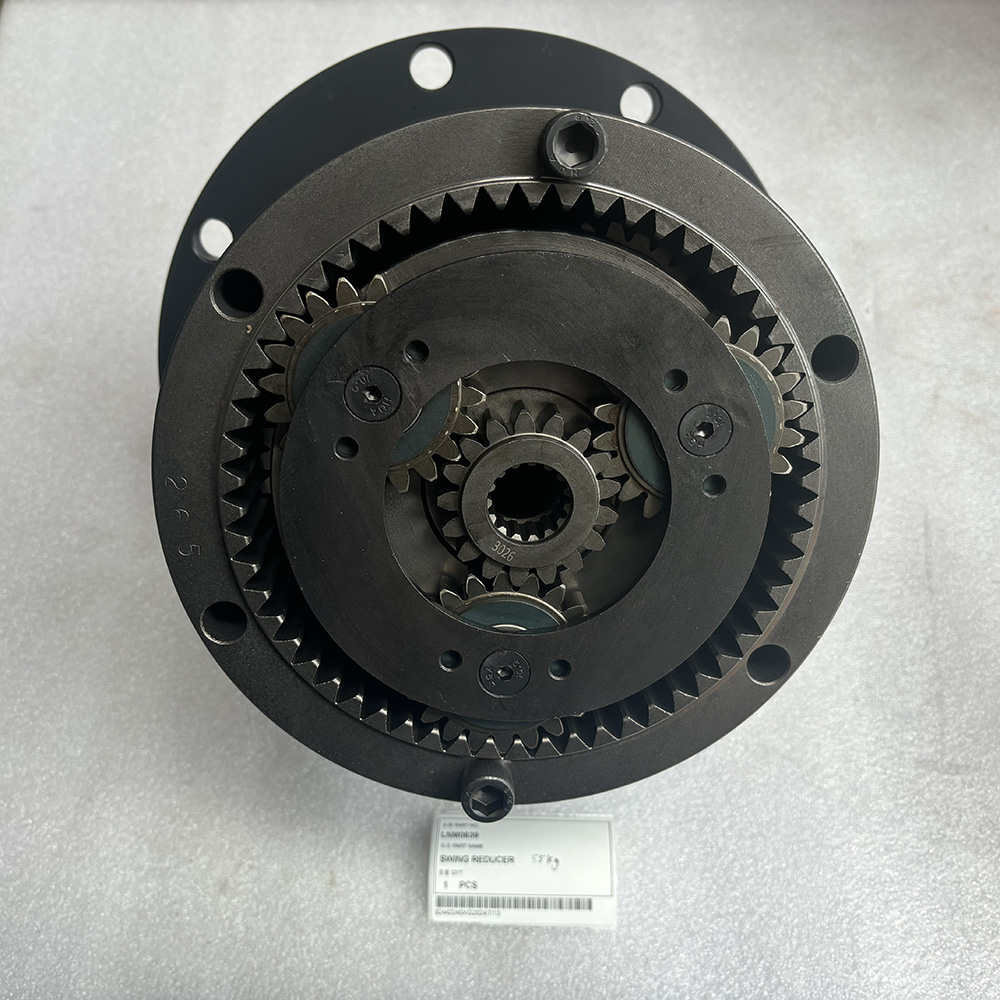

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

SPARKLING OEM Swing Gear Box – Precision & Reliability You Can Trust

At SPARKLING MACHINERY, founded in 2013, we have dedicated ourselves to producing high-quality excavator parts with an emphasis on stability, precision, and durability. Our OEM swing gear box is designed to meet the rigorous demands of heavy-duty excavator operations, ensuring smooth rotational movement and optimum performance across diverse working conditions.

Crafted with advanced manufacturing techniques and subjected to strict quality control, the SPARKLING OEM swing gear box guarantees exceptional reliability and long service life. Compatible with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, our swing gear box is engineered to perfectly integrate into your equipment, providing flawless operation and reducing downtime.

We understand how crucial every component is in your machinery’s efficiency. That’s why our swing gear box not only delivers outstanding mechanical performance but also comes with customized solutions and professional technical support tailored to your specific needs. Our team offers meticulous consultation and continuous service, ensuring you receive unparalleled care and value.

Choosing the SPARKLING OEM swing gear box means choosing a trusted partner who prioritizes your success by providing competitive prices without compromising quality. By reducing maintenance costs and improving equipment reliability, our product helps maximize your productivity and return on investment.

Experience the best in excavator parts with SPARKLING MACHINERY — where innovation, precision, and customer care meet.

Product Images

Frequently Asked Questions

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

JCB Swing Gearbox Assembly for JS70, PC60-7 & PC70-7 Excavators – LNM0639

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

Construction Machinery Spare Parts 8.8Kg 6215-11-5140 Exhaust Manifold For Komatsu Engines Sa12v140 Saa12v140e-3a And Wa900-3 Wheel Loaders

SPARKLING MACHINERY New Exhaust Manifold (6215-11-5140) is a dedicated engine exhaust component for EGS1000, EGS1050 and EGS1200 heavy-duty machinery (generators, construction equipment included). As a core part of the exhaust system, it collects exhaust gas from engine cylinders and channels it efficiently into the exhaust pipe, ensuring smooth gas flow and optimal engine backpressure. This preserves engine power, cuts fuel consumption and helps meet emission standards during high-load operations.

· Engine Compatibility - Komatsu engines:SA12V140 and SAA12V140E-3A models.

· Machine Compatibility - heavy machinery:D475A-3, D475A-5, HD985-3, HD985-5 dump trucks, and WA900-3 wheel loaders.

· More: EGS1000, EGS1050, EGS1200

38Q8-40101 Final Drive For Hyundai Machine Model R250LC9 R250LC9A R260LC9S

Specifications & Compatibility

This part is a critical component of the excavator's travel device, responsible for driving the tracks.

Primary Application: It is widely used in 25–34 ton Hyundai excavators, specifically models like the R290LC-9, R300LC-9S, and R340L.

Components: It is an integrated unit consisting of a hydraulic travel motor and a reduction gearbox.

38Q8-40101, 38Q840101, Hyundai 38Q8-40101Compatible Hyundai Models

According to technical parts lists, this assembly is used in the following series:

R250LC-9 / R260LC-9A / R260LC-9S/R290LC-7A / R290LC-9 / R290LC-9MH/R300LC-9A / R300LC-9S / R300LC-9SH/R340LC-7 (India)

Weight: 406kg

Exact Fitment: 100% compatible replacement for Hyundai OEM part number 38Q8-40101.

Heavy-Duty Performance: Optimized for 29-30 ton crawler excavators, providing powerful torque and reliable travel performance in harsh 2026 mining/construction environments.

Full Assembly: Includes both the high-torque hydraulic motor and the planetary gearbox for a "plug-and-play" replacement.

Quality Assurance: Every unit is 100% factory tested for pressure and leakage to meet or exceed original specifications.

Global Logistics 2026: In-stock and ready for immediate dispatch via DHL, FedEx, or sea freight to minimize machine downtime.

Kubota Oil Cooler RD451‑64050 / RD551‑64050 for KX057‑4 U48‑4 U55‑4 Excavators

The Kubota Oil Cooler (part nos. RD451‑64050, RD451‑64053, RD551‑64050, RD551‑64052) is a premium hydraulic oil radiator engineered for various Kubota excavators and compact machines, including models like KX057‑4, U48‑4, U55‑4, and more. This high-performance aluminium oil cooler ensures efficient heat dissipation and maintains optimal hydraulic oil temperatures under continuous heavy-duty operation. Manufactured to OEM standards and available in both genuine and aftermarket options, it offers excellent durability, corrosion resistance, and a perfect drop-in fit.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879