SPARKLING PC228 Radiator Core – Durable Excavator Cooling Solution

The Radiator Core (Part No. 22U-03-22113 / 22U-03-22112 / 22U-03-22111) is a high-quality cooling component designed specifically for Komatsu PC228 and PC228US excavators. This core is engineered to maintain optimal engine temperature, ensuring reliable machine performance under extreme working conditions.

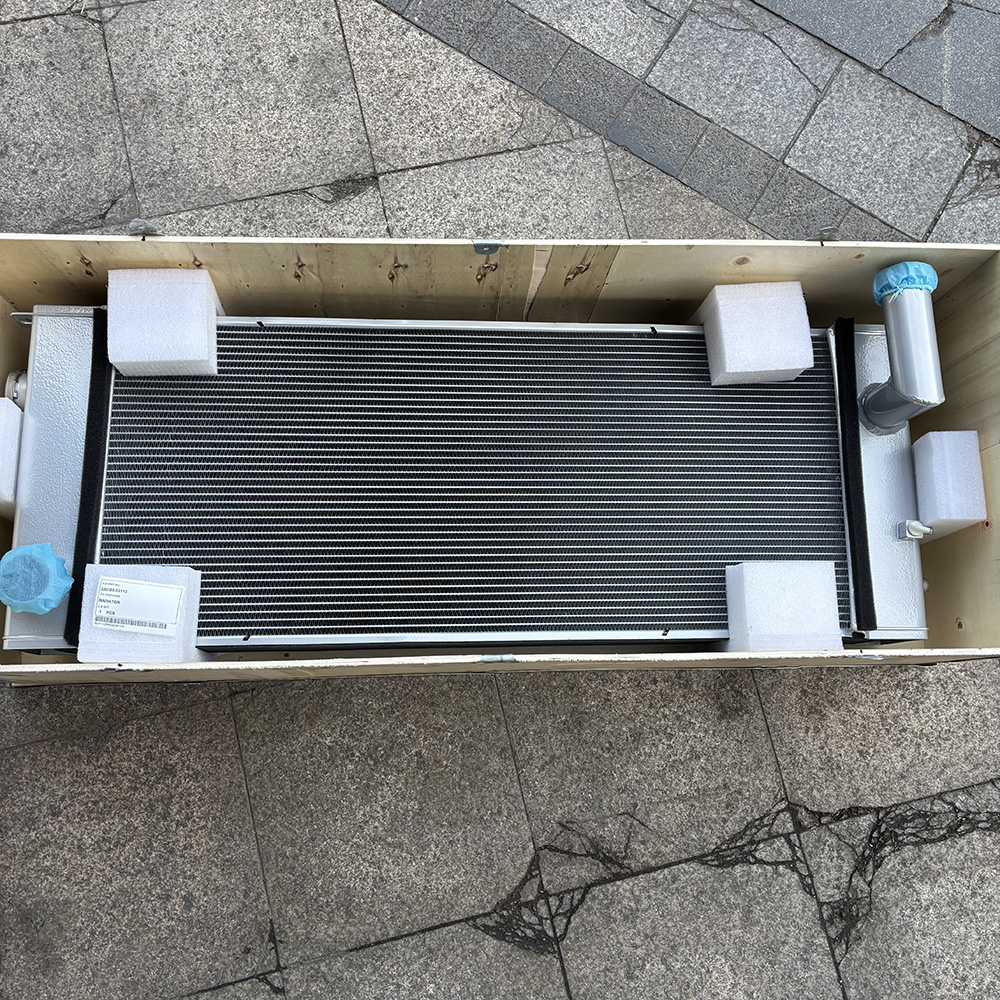

Constructed with durable aluminum alloy and efficient heat dissipation fins, this radiator core guarantees excellent thermal performance, corrosion resistance, and long service life. It is a direct-fit replacement, tested to meet or exceed OEM standards.

SPARKLING PC228 Radiator Core – Reliable Cooling for Optimal Excavator Performance

The SPARKLING PC228 radiator core is engineered to deliver exceptional cooling performance, ensuring your excavator runs efficiently even under the most demanding conditions. Manufactured by SPARKLING MACHINERY, a trusted name in excavator parts since 2013, this radiator core exemplifies precision, durability, and reliability, aligning with our commitment to quality and customer satisfaction.

Designed specifically for PC228 models, the SPARKLING radiator core helps maintain optimal engine temperature by effectively dissipating heat. Its robust construction and advanced materials resist corrosion and wear, enabling stable operation over extended periods. Whether you are working on a construction site or in harsh environments, this radiator core guarantees your machine’s thermal management is never compromised.

SPARKLING MACHINERY’s rigorous quality control and strict manufacturing standards ensure each PC228 radiator core meets international performance benchmarks. Compatible with major excavator brands like Caterpillar, Komatsu, Hitachi, and Volvo, it seamlessly integrates into your existing system, providing a dependable upgrade or replacement option.

With customizable solutions, expert technical support, and comprehensive after-sales service, SPARKLING MACHINERY stands as your reliable partner in maintaining excavator efficiency and longevity. Our competitive pricing combined with superior product quality helps reduce operational costs while upholding safety and performance.

Trust in SPARKLING’s PC228 radiator core for consistent, worry-free excavator cooling — engineered to support your productivity on every job.

Detailed display

FAQ

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

If you have any questions about our goods or services, please feel free to contact us.

PC228 PC228US 22U-03-22113 22U-03-22112 22U-03-22111 22U0322113 RADIATOR CORE

The Radiator Core (Part No. 22U-03-22113 / 22U-03-22112 / 22U-03-22111) is a high-quality cooling component designed specifically for Komatsu PC228 and PC228US excavators. This core is engineered to maintain optimal engine temperature, ensuring reliable machine performance under extreme working conditions.

Constructed with durable aluminum alloy and efficient heat dissipation fins, this radiator core guarantees excellent thermal performance, corrosion resistance, and long service life. It is a direct-fit replacement, tested to meet or exceed OEM standards.

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC200B EC200D EC210B 14541069 SWING REDUCER

SPARKLING MACHINERY NEW EC200B EC200D EC210B 14541069 Swing Reducer is a premium China-made transmission component specifically engineered for EC200B, EC200D, and EC210B excavators. As a critical part of the swing system, it converts high-speed, low-torque input from the hydraulic motor into low-speed, high-torque output, enabling smooth and controlled rotation of the upper structure (boom, arm, and bucket) during precision positioning, material handling, and medium to heavy-duty operations.

Designed to original equipment standards, it maintains stable power transmission and efficient torque conversion even under continuous rotational stress and varying loads. With optimized gear meshing design for minimal friction, noise, and wear, it adapts seamlessly to harsh working environments, from construction sites to agricultural fields. Backed by strict quality verification, it guarantees consistent performance to support uninterrupted machinery operation.

HYUNDAI HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW HW210 R170W9 R200W7 R200W7A ZGAQ-02343 CROSS-JOINT SPARKLING MACHINERY

SPARKLING MACHINERY NEW ZGAQ-02343 Cross-Joint is a core power transmission component for Hyundai HW210/R170W9/R200W7/R200W7A excavators (construction/mining use). It enables flexible power transfer between rotating shafts at varying angles, ensuring smooth torque transmission.

Meeting Hyundai OEM standards (Part No.: ZGAQ-02343), it features high wear resistance and impact resistance, guaranteeing seamless compatibility and reliable long-term transmission performance.

John Deere EXCAVATOR PARTS MADE IN CHINA NEW 380GLC 1210E 670G 290GLC 310K 870G 180GLC RE536274 PRESSURE RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW 380GLC 1210E 670G 290GLC 310K 870G 180GLC RE536274 Pressure Relief Valve is a dedicated hydraulic safety component for John Deere 380GLC, 1210E, 670G, 290GLC, 310K, 870G, and 180GLC crawler excavators (widely used in construction, mining, and agricultural infrastructure projects). As the "hydraulic pressure guardian", it automatically releases excess pressure when it exceeds the set threshold—protecting pumps, cylinders, and hoses from damage during high-intensity tasks like heavy digging, rock breaking, and material lifting, while ensuring stable system operation.

Meeting John Deere OEM standards (part no. RE536274), it maintains a precise pressure range of 32-36 MPa, endures -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and ensures instant pressure relief. Strict testing guarantees seamless compatibility with the seven John Deere models and long-term hydraulic system safety.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879