SPARKLING PC70-7 Swing Gear Reducer – Durable & Precise Excavator Part

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

SPARKLING PC70-7 Swing Gear Reducer – Reliable Performance for Your Excavator

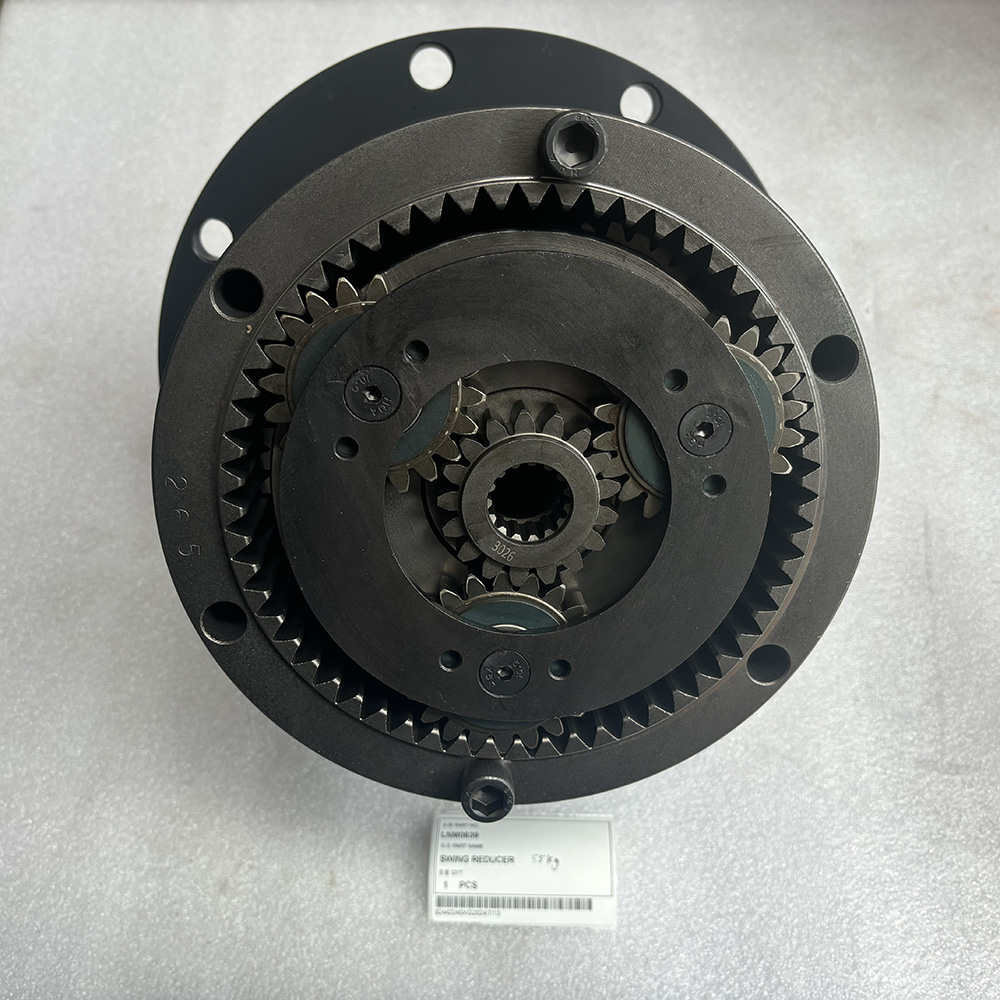

Introducing the SPARKLING PC70-7 swing gear reducer, a High Quality component designed to enhance the efficiency and durability of your excavator. Manufactured by SPARKLING MACHINERY, a leading brand established in 2013, this swing gear reducer is engineered with precision and built for stability, ensuring smooth and reliable swing operation on your PC70-7 model excavator.

Our swing gear reducer stands out due to its robust construction and superior gear design, which minimizes wear and optimizes torque transmission, enabling your excavator to perform demanding tasks with confidence. Each unit undergoes rigorous quality control processes, guaranteeing consistent performance even in the toughest working environments.

SPARKLING MACHINERY is committed to providing high-quality excavator parts that not only meet but exceed industry standards. With extensive experience in manufacturing hydraulic components, undercarriage systems, engine parts, and more, we ensure compatibility with leading brands such as Caterpillar, Komatsu, Hitachi, and Volvo. We understand the critical role the PC70-7 swing gear reducer plays in operational accuracy and safety, and our product is tailored to deliver long-lasting service and exceptional value.

Choosing the SPARKLING PC70-7 swing gear reducer means investing in durability and performance. We also offer customized solutions, technical support, and continuous service to keep your machinery running optimally while helping you reduce maintenance costs. Our goal is to support you with reliable parts and attentive customer care, making your equipment maintenance simpler and more efficient.

Experience the perfect balance of quality, price, and service with SPARKLING’s PC70-7 swing gear reducer – your trusted partner in excavator maintenance.

Picture Show

Question you may concern

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

JCB Swing Gearbox Assembly for JS70, PC60-7 & PC70-7 Excavators – LNM0639

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

Excavator Spare Parts LECU/LCBBC-LHN VALVE ASSY for Case Construction Equipment CX800B CX700B CX800 CX700

The Excavator Spare Parts LECU/LCBBC-LHN VALVE ASSY is a premium electro-hydraulic control component for Case CX800B/CX700B/CX800/CX700. It precisely regulates hydraulic flow/pressure, ensures responsive heavy-duty operation, and seamlessly integrates with Case’s system in harsh construction environments.

Key Features

· Custom-engineered for Case target excavator models

· Electro-hydraulic integration for precise, responsive control

· High-pressure resistance to withstand heavy-duty demands

· Stable performance under extreme temperatures and conditions

· Compliant with Case OEM specifications for seamless integration

Compatible Models

· Case Construction Equipment Excavators: CX800B, CX700B, CX800, CX700

KUBOTA MADE IN CHINA SPARKLING MACHINERY NEW CX300C CX350C LJ018980 SOLENOID VALVE

SPARKLING MACHINERY NEW CX300C CX350C LJ018980 Solenoid Valve is a dedicated hydraulic control component exclusively designed for CX300C and CX350C excavators. As a key part of the excavators’ hydraulic system, it precisely regulates the flow and direction of hydraulic oil to control critical working mechanisms—including boom lifting, arm movement, and bucket operation. This function is essential for achieving smooth, responsive hydraulic performance during heavy-duty tasks like deep digging, large-volume material loading, and mining operations, where precise control directly impacts work efficiency and task accuracy.

Engineered to match original equipment performance standards, it maintains stable valve operation even under harsh working conditions, such as high hydraulic pressure, continuous vibration, and temperature fluctuations. It prevents oil leakage and hydraulic signal lag, avoiding unresponsive movements or uneven mechanism operation. Backed by strict performance verification, it guarantees long-term reliability to support uninterrupted operation of CX300C and CX350C excavators.

SPARKLING MACHINERY TRACK-TYPE TRACTOR CAT D7 558-5127 5585127 VALVE GP-QDR ORIGINAL 27KG

The 558-5127 / 5585127 Valve GP-QDR is a genuine replacement hydraulic control valve designed for CAT D7 Track-Type Tractors. Manufactured to Caterpillar OEM standards and weighing 27KG, this original valve ensures high precision fluid control in demanding construction and earthmoving environments.

As a critical component in the hydraulic control system, the GP-QDR valve regulates the flow and pressure to various functions of the bulldozer, helping to deliver reliable and responsive operational performance. SPARKLING MACHINERY offers this valve as part of our premium product lineup—ideal for equipment owners seeking both authenticity and performance assurance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879