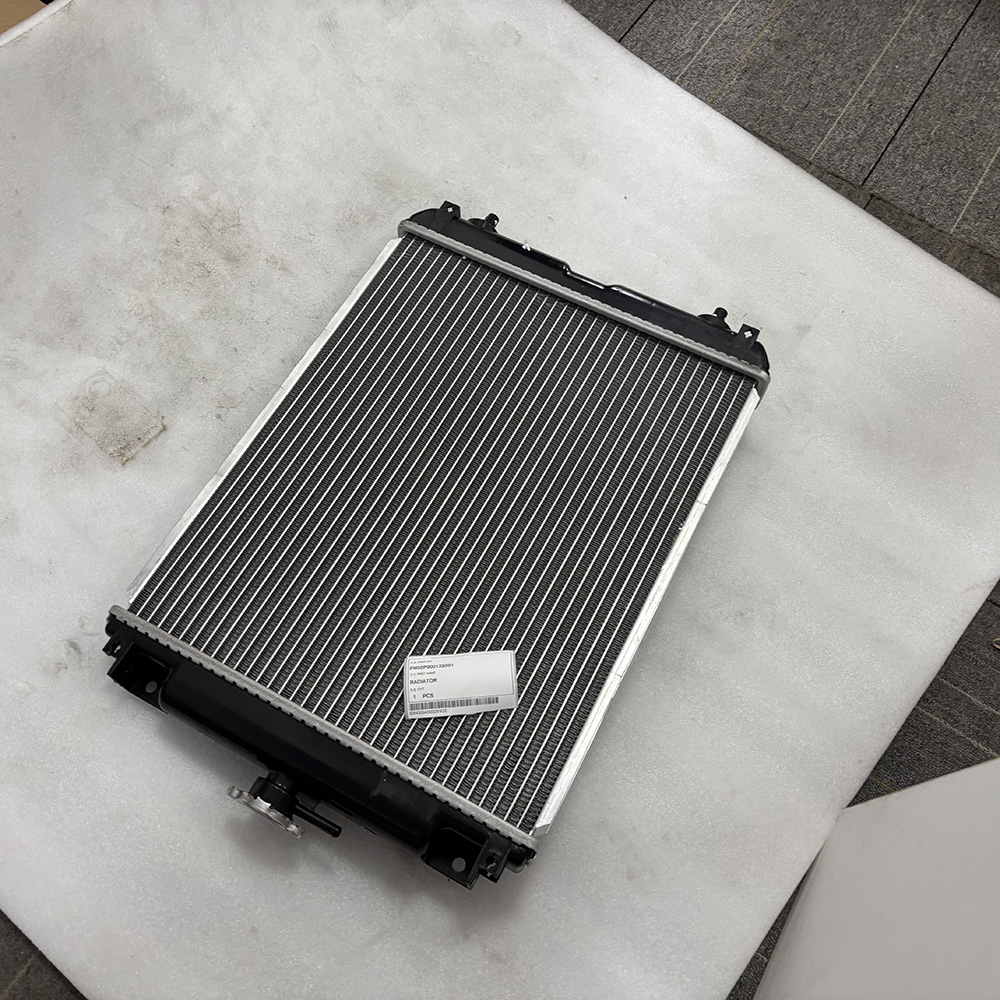

SPARKLING PM05P00013S001 Radiator – Durable Excavator Cooling Solution

The PM05P00013S001 Radiator, offered by SPARKLING MACHINERY, is a high-quality replacement cooling system component specifically designed for New Holland E27B/E27BSR, CASE CX27B, and Kobelco SK27SR-3 mini excavators.

Built using premium aluminum and designed for efficient heat dissipation, this radiator ensures optimal engine performance and longevity even in demanding work environments. It matches OEM specifications and comes ready to install—making it an ideal choice for maintenance, replacement, or refurbishment.

SPARKLING PM05P00013S001 Radiator – High Quality Excavator Cooling Solution

The SPARKLING PM05P00013S001 radiator is engineered for excavators demanding superior cooling performance and durability. As a key product from SPARKLING MACHINERY, a trusted name since 2013, this radiator guarantees exceptional stability, precision, and longevity under harsh working conditions.

Designed with advanced manufacturing techniques and subjected to rigorous quality control, the PM05P00013S001 radiator ensures efficient heat dissipation, preventing engine overheating and maintaining optimal operating temperatures. Compatible with leading excavator brands like Caterpillar, Komatsu, Hitachi, and Volvo, it fits seamlessly into your heavy machinery to enhance performance and reduce downtime.

SPARKLING MACHINERY’s commitment to innovation and quality is evident in every detail of the PM05P00013S001 radiator. Offering customized solutions and expert technical support, the brand delivers not just a product but a comprehensive service experience tailored to your specific needs. Meticulous consultation and ongoing assistance help maximize equipment lifespan while controlling costs effectively.

Whether you are upgrading an existing system or replacing worn parts, the SPARKLING PM05P00013S001 radiator combines competitive pricing with uncompromised quality. Its robust design guarantees reliability in the toughest environments, making it the perfect choice for professionals seeking efficiency and peace of mind in excavator maintenance.

Trust SPARKLING MACHINERY to keep your excavators cool, performing, and productive – the radiator solution for demanding jobs worldwide.

Product Image

FAQ

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

SPARKLING MACHINERY E27B E27BSR CX27B SK27SR-3 PM05P00013S001 RADIATOR

The PM05P00013S001 Radiator, offered by SPARKLING MACHINERY, is a high-quality replacement cooling system component specifically designed for New Holland E27B/E27BSR, CASE CX27B, and Kobelco SK27SR-3 mini excavators.

Built using premium aluminum and designed for efficient heat dissipation, this radiator ensures optimal engine performance and longevity even in demanding work environments. It matches OEM specifications and comes ready to install—making it an ideal choice for maintenance, replacement, or refurbishment.

SANY SSR260C SANY SSR180C SANY SSR120C SANY SSR200C SANY SSR220C 61009935 HYDRAULIC PUMP ASSY

The 61009935 Hydraulic Pump Assembly is a core component designed to deliver consistent and reliable hydraulic power to your SANY single-drum road rollers. Whether it’s compaction on highways, industrial zones, or large infrastructure projects, this pump ensures optimal performance and operational stability.

Key Features:

-

Perfect fit for SANY SSR120C / SSR180C / SSR200C / SSR220C / SSR260C

-

Delivers stable hydraulic pressure and long-lasting performance

-

Built with high-quality seals and precision-machined internals

-

Designed for heavy-duty compaction environments

-

Rigorously tested for flow rate, pressure, and durability

R110-7 R140LC9 R140W7 R170W7A R160LC9 R180LC9 R250LC-9 31N6-91230 27V DC 21W SOLENOID VLV-BREAKER ORIGINAL QUALITY 0.8KG

Original Quality Solenoid Valve 31N6-91230 27V DC 21W for Hyundai R Series Excavators

The 31N6-91230 Solenoid Valve (Breaker Valve) is an original quality electrical hydraulic component specifically designed for Hyundai excavators including R110-7, R140LC9, R140W7, R160LC9, R170W7A, R180LC9, and R250LC-9.

This 27V DC / 21W solenoid valve plays a critical role in hydraulic breaker (hammer) control systems, enabling or blocking hydraulic oil flow with high precision. Manufactured with premium copper coils, high-temperature insulation, and anti-corrosion coatings, this valve delivers fast response, stable operation, and long service life, even under high-frequency operations.

280-2357 Gear for Caterpillar Mini Excavator 303.5C 303.5D 303.5E | Durable Replacement Part

The 280-2357 gear is a planetary final drive reduction gear for Caterpillar mini excavators 303.5C/303.5D/303.5E (also fits 303C CR/303.5CR/303.5E2/304/304E2). It works in the travel motor gearbox to reduce speed, amplify torque, and drive track movement smoothly for landscaping, utility, and small-scale construction tasks.

Key Features

· OEM-Matched Precision: 20CrMnTi alloy steel, precision-machined teeth, exact pitch/diameter—no modification needed for Cat models.

· Durable Construction: Carburized tooth surface (58–62 HRC) for wear resistance; shot-peened for fatigue strength.

· High Torque Capacity: Optimized for 1,800 N·m max torque; low backlash (<0.05mm) for stable track operation.

· Plug-and-Play Installation: Direct fit into final drive assembly; 45-minute replacement with basic hand tools.

· Long Service Life: 8,000+ hours lifespan; 100% tested for tooth profile, hardness, and dimensional accuracy.

Compatible Equipment

· Mini Excavators: Caterpillar 303.5C, 303.5D, 303.5E, 303C CR, 303.5CR, 303.5E2, 304, 304E2.

· Interchangeable Part Numbers: 280-2357, 2802357.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879