SPARKLING R140W-9A Excavator Shaft – Durable & Precise

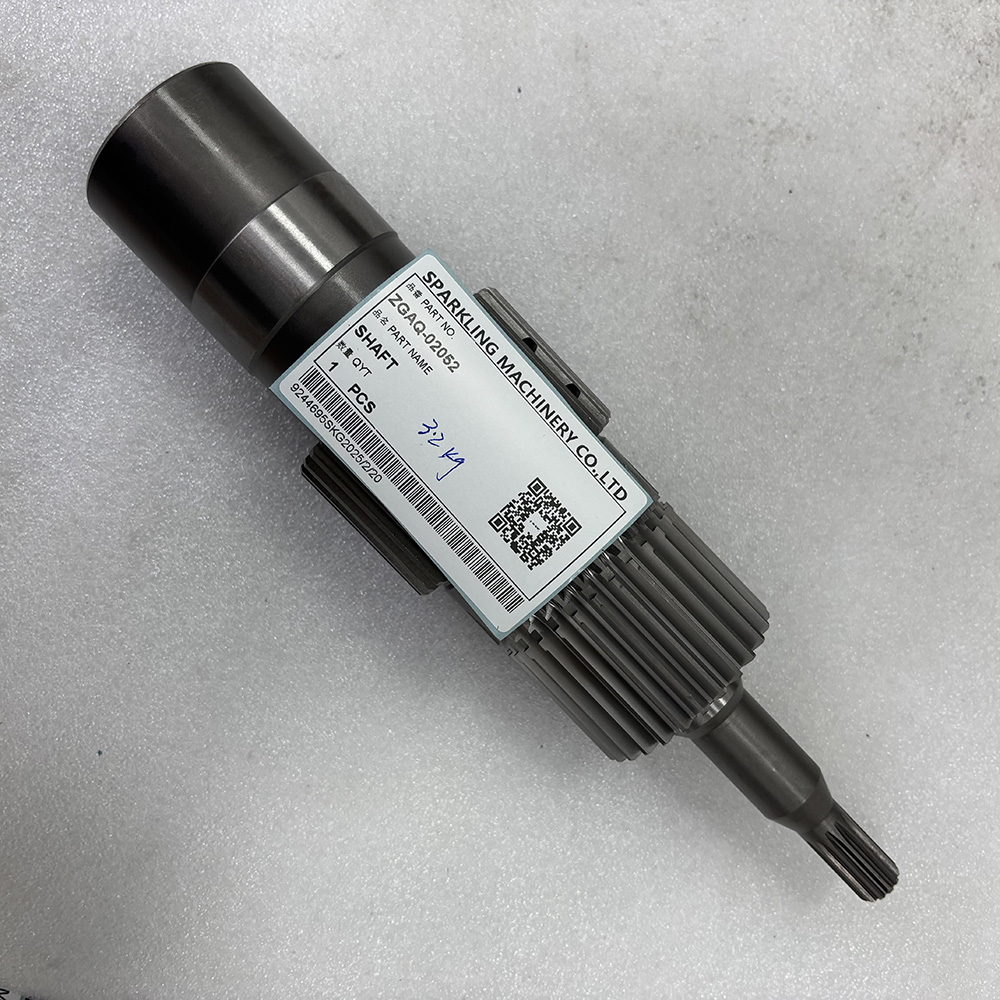

The ZGAQ-02052 Shaft-Input is a critical drivetrain component specifically designed for HYUNDAI Wheel Excavators, including models R140W-7, R140W-9A, R140W-9S, R170W-7, and R170W-7A. This input shaft is responsible for transmitting torque efficiently from the transmission to the differential or gearbox, ensuring smooth and reliable machine operation.

Manufactured with high-grade alloy steel and precision machining, the ZGAQ-02052 offers excellent durability, high-load resistance, and long service life — even under the harsh conditions of construction and excavation environments.

SPARKLING R140W-9A Excavator Shaft – Precision and Reliability You Can Trust

SPARKLING MACHINERY proudly presents the R140W-9A excavator shaft, engineered to meet the highest standards of durability and performance. Since 2013, SPARKLING has specialized in High Quality excavator parts, delivering components that embody stability, precision, and perseverance. Designed for seamless compatibility with major brands like Caterpillar, Komatsu, Hitachi, and Volvo, the R140W-9A excavator shaft guarantees reliable operation in demanding environments.

Crafted through stringent manufacturing processes and rigorous quality control, this shaft ensures optimal strength and longevity, reducing downtime and maintenance costs. Whether you operate heavy machinery in construction, mining, or infrastructure projects, SPARKLING’s R140W-9A excavator shaft stands out as a dependable component tailored to enhance your equipment’s efficiency.

Beyond quality products, SPARKLING MACHINERY offers expert consultation, customized solutions, and continuous technical support, reflecting a commitment to customer satisfaction and industry innovation. Our comprehensive global sales network ensures timely delivery and competitive pricing without compromising quality.

Choose SPARKLING’s R140W-9A excavator shaft and experience peace of mind with every project. Trust in our expertise and dedication to providing reliable, cost-effective parts designed to keep your excavator operating at peak performance.

Product Images

Q&A

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

HYUNDAI WHEEL EXCAVATOR R140W-7 R140W-9A R140W-9S R170W-7 R170W-7A ZGAQ-02052 SHAFT-INPUT

The ZGAQ-02052 Shaft-Input is a critical drivetrain component specifically designed for HYUNDAI Wheel Excavators, including models R140W-7, R140W-9A, R140W-9S, R170W-7, and R170W-7A. This input shaft is responsible for transmitting torque efficiently from the transmission to the differential or gearbox, ensuring smooth and reliable machine operation.

Manufactured with high-grade alloy steel and precision machining, the ZGAQ-02052 offers excellent durability, high-load resistance, and long service life — even under the harsh conditions of construction and excavation environments.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC120D EC135B EC140B EC140C EC140D 14591545 PRESSURE SWITCH SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC120D EC135B EC140B EC140C EC140D 14591545 Pressure Switch is a key hydraulic safety component for Volvo EC120D, EC135B, EC140B, EC140C, and EC140D excavators (widely used in construction, municipal engineering, and light mining). As the "hydraulic pressure sentinel", it real-time monitors pressure changes in hydraulic circuits—automatically triggering alerts or protective actions via the excavator’s control unit when pressure goes beyond safe limits. This prevents overpressure damage to pumps, valves, and cylinders during tasks like digging or boom lifting, while ensuring stable operation by avoiding underpressure-related function failures.

Meeting Volvo OEM standards (part no. 14591545), it endures -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and guarantees precise pressure sensing. Strict testing ensures seamless compatibility with the five Volvo models and long-term hydraulic system safety.

EXCAVATOR PARTS MADE IN CHINA NEW 201-45342/201-46298 FUEL PUMP SPARKLING MACHINERY

SPARKLING MACHINERY NEW 201-45342 201-46298 Fuel Pump is a critical engine fuel supply component designed for a wide range of excavator models (widely used in construction, mining, municipal engineering, and large-scale earthmoving projects). As the "engine fuel core", it precisely pressurizes and delivers diesel fuel to the combustion chamber—ensuring stable, consistent fuel flow during high-intensity tasks like heavy digging, rock breaking, and long-hour equipment operation, while optimizing fuel atomization to maintain efficient combustion and avoid engine power loss.

Meeting industry OEM standards (part nos. 201-45342 / 201-46298), it endures -30°C to 120°C working temperatures, resists diesel fuel corrosion and equipment vibration, and guarantees reliable fuel pressure output (rated pressure deviation <0.2 bar). Strict performance testing ensures seamless compatibility with applicable excavator models and long-term stability of the engine fuel system.

HYUNDAI HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW HL780-7A HL7803A R200W7 ZGAQ-00100 HUB SEAL SPARKLING MACHINERY

SPARKLING MACHINERY's new ZGAQ-00100 Hub Seal is a core sealing component specifically designed for Hyundai HL780-7A/HL7803A/R200W7 excavators, suitable for construction and mining applications. It serves to seal the hub assembly, preventing lubricant leakage and the ingress of dust, water, and other contaminants.

Compliant with Hyundai OEM standards (Part No.: ZGAQ-00100), this component exhibits excellent sealing performance and wear resistance, ensuring seamless compatibility with original equipment and long-term stable operational performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879