SPARKLING R210LC-9 Valve Replacement

The Hyundai Solenoid Valve (XKCH‑00025 / XKCH‑00022) is an OEM-grade hydraulic control valve compatible with both wheel and crawler excavators—including models R140LC‑9 / R140W‑9, R145CR‑9, R160LC‑9, SK210LC‑9, R210LC‑9, R250LC‑9, R290LC‑9, R360LC‑9, R480LC‑9, R520LC‑9, HW140, HW210, HX140L, HX160L, HX180L, HX220L, HX260L, HX300L, HX480L, R1200‑9, and more.

Built to Hyundai exacting standards, this valve ensures flawless hydraulic actuation and pressure control. It is supplied as a direct-fit replacement offering durable, tested performance, with options for OEM or high-quality aftermarket supply .

The SPARKLING R210LC-9 valve replacement is engineered for reliability and precision, designed specifically to meet the rigorous demands of your excavator. Backed by SPARKLING MACHINERY’s dedication since 2013 to quality and innovation, this valve ensures optimal hydraulic performance, extending the life of your R210LC-9 excavator.

Crafted from high-grade materials and subjected to strict quality controls, the valve replacement guarantees smooth operation and durability under varying working conditions. Whether you’re digging, lifting, or loading, this valve plays a critical role in maintaining hydraulic efficiency, reducing wear, and preventing costly downtime.

Compatible with a broad range of excavator models, it fits seamlessly and offers easy installation, making it an ideal part for maintenance or upgrades. SPARKLING also provides technical support and customized solutions to suit your specific needs, helping you maximize equipment uptime and lower operating costs.

Choose the SPARKLING R210LC-9 valve replacement for stable performance, precision engineering, and competitive pricing. Join thousands of satisfied customers worldwide who trust SPARKLING MACHINERY to keep their excavators running strong. Elevate your machine’s reliability with a part designed to last.

Detailed display

Question you may concern

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

If you have any questions about our goods or services, please feel free to contact us.

Hyundai Solenoid Valve XKCH‑00025 / XKCH‑00022 for R140LC‑9, R210LC‑9, R250LC‑9, R480LC‑9 Excavators

The Hyundai Solenoid Valve (XKCH‑00025 / XKCH‑00022) is an OEM-grade hydraulic control valve compatible with both wheel and crawler excavators—including models R140LC‑9 / R140W‑9, R145CR‑9, R160LC‑9, SK210LC‑9, R210LC‑9, R250LC‑9, R290LC‑9, R360LC‑9, R480LC‑9, R520LC‑9, HW140, HW210, HX140L, HX160L, HX180L, HX220L, HX260L, HX300L, HX480L, R1200‑9, and more.

Built to Hyundai exacting standards, this valve ensures flawless hydraulic actuation and pressure control. It is supplied as a direct-fit replacement offering durable, tested performance, with options for OEM or high-quality aftermarket supply .

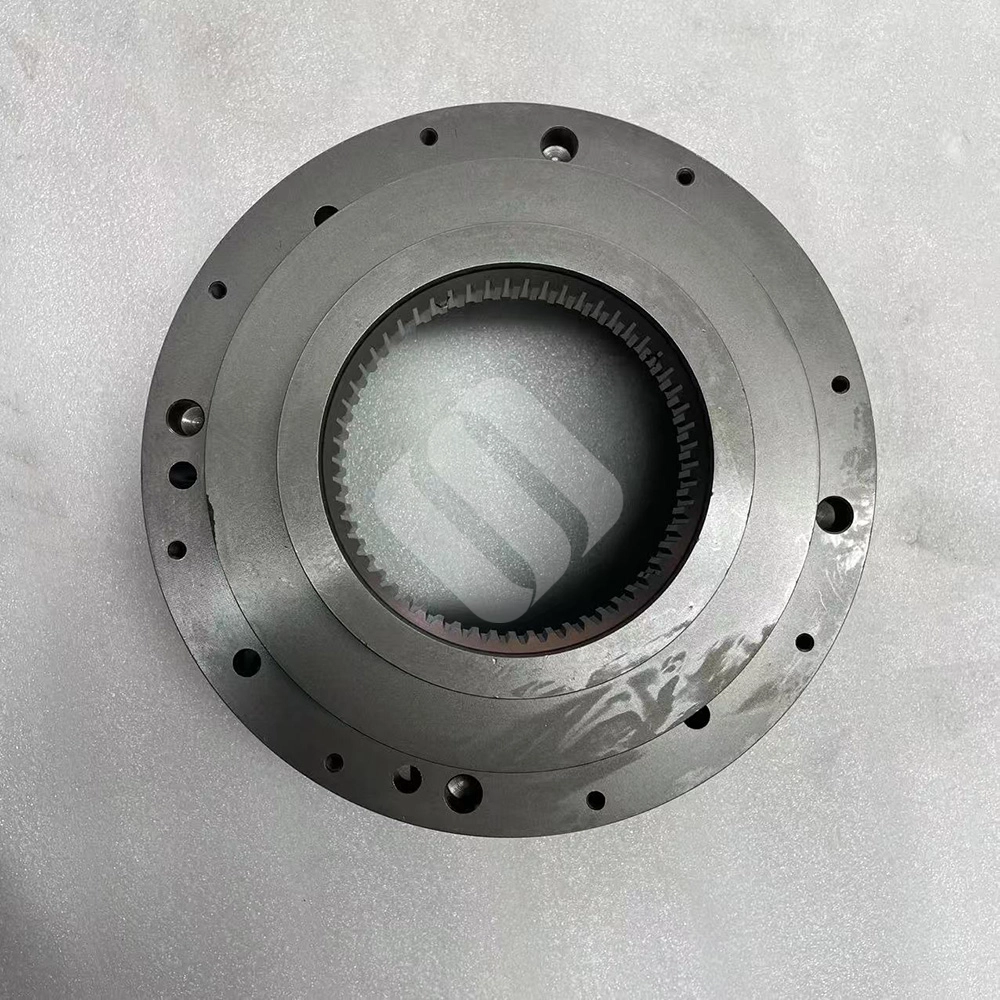

HYUNDAI EXCAVATOR R170W-7 R180W-9 R210W-9 ZGAQ-02211 GEAR RING 13.6kg CHINA MADE

The Hyundai ZGAQ-02211 Gear Ring is a high-quality China-made replacement component designed for Hyundai excavators R170W-7, R180W-9, and R210W-9. Built to deliver reliable performance and durability, this gear ring weighs 13.6 kg and offers a precise fit for the swing mechanism or other drivetrain applications.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC250D EC250E EC300D EC300E PL3005D 14591251 RELIEF VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC250D EC250E EC300D EC300E PL3005D 14591251 Relief Valve is a dedicated hydraulic safety component for VOLVO EC250D, EC250E, EC300D, EC300E, and PL3005D crawler excavators (heavy-duty equipment for mining, large-scale construction, and infrastructure projects). As the core safety guard of the hydraulic system, it precisely limits maximum pressure to protect pumps, cylinders, and pipelines from overload damage during rock breaking, bulk ore loading, and deep excavation.

Meeting VOLVO OEM standards (part no. 14591251), it endures 34 MPa pressure, -25°C to 105°C temperature fluctuations, and continuous vibration. It resists oil contamination and wear, ensuring long-term reliability for the five VOLVO models, with strict testing guaranteeing seamless compatibility and safe operation.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879