SPARKLING R210W-9 LH Joint Housing – Durable Excavator Part

The ZGAQ-02351 JOINT HOUSING-LH is a key left-hand structural component used in the front axle or steering assembly of Hyundai wheel excavators R200W-7, R200W-7A, and R210W-9. This joint housing provides crucial support and alignment for the axle shaft and wheel movement, ensuring smooth articulation, durability, and safe machine operation.

Crafted with high-strength cast steel and manufactured to OEM-level precision, this component is designed to endure the stress and load from rugged construction conditions. It’s an ideal replacement part for restoring steering performance and structural integrity.

SPARKLING R210W-9 LH Joint Housing: Precision, Durability, and Performance

At SPARKLING MACHINERY, we pride ourselves on delivering High Quality excavator parts crafted for reliability and excellence. The R210W-9 LH joint housing stands out as a pivotal component designed to enhance the structural integrity and operational efficiency of your excavator. Manufactured with advanced engineering techniques and stringent quality controls, this joint housing is compatible with leading excavator models, ensuring a perfect fit and superior durability.

Built from high-grade materials, the R210W-9 LH joint housing withstands rigorous working conditions, resisting wear, corrosion, and mechanical stress. Whether you operate in construction, mining, or heavy-duty landscaping, this component guarantees longevity and stable performance, minimizing downtime and maintenance costs. Its precision design supports smooth joint articulation, essential for maintaining optimal machine responsiveness and safety.

Backed by SPARKLING’s commitment to innovation and customer satisfaction, this product comes with tailored technical support and consultation services. Our expertise covers hydraulic components, undercarriage systems, engine and electrical parts, and more, ensuring comprehensive solutions for your R210W-9 excavator needs. Choose SPARKLING MACHINERY’s R210W-9 LH joint housing for a reliable, cost-effective upgrade that boosts your machine’s performance and profitability.

Experience the difference with SPARKLING — where quality meets precision, and your excavator parts needs find their perfect match.

Product Image

Q&A

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

ZGAQ-02351 Joint Housing-LH for Hyundai R200W-7 R210W-9 Excavator | SPARKLING MACHINERY

The ZGAQ-02351 JOINT HOUSING-LH is a key left-hand structural component used in the front axle or steering assembly of Hyundai wheel excavators R200W-7, R200W-7A, and R210W-9. This joint housing provides crucial support and alignment for the axle shaft and wheel movement, ensuring smooth articulation, durability, and safe machine operation.

Crafted with high-strength cast steel and manufactured to OEM-level precision, this component is designed to endure the stress and load from rugged construction conditions. It’s an ideal replacement part for restoring steering performance and structural integrity.

HYUNDAI EXCAVATOR PARTS MADE IN CHINA NEW R260LC9S R290LC9 R290LC9MH R320LC7 R330LC9S XKBF-01503 VALVE ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW R260LC9S R290LC9 R290LC9MH R320LC7 R330LC9S XKBF-01503 Valve Assy is a dedicated hydraulic control assembly for Hyundai R260LC9S, R290LC9, R290LC9MH, R320LC7, and R330LC9S crawler excavators (widely used in heavy construction, mining, and infrastructure projects). As the "hydraulic control center" of the excavator, it integrates multiple valves to regulate oil flow, pressure, and direction—powering key functions like boom lifting, bucket digging, and swing movements, ensuring smooth and precise operation during high-intensity tasks.

Meeting Hyundai OEM standards (part no. XKBF-01503), it endures 32 MPa working pressure, -30°C to 95°C temperatures, resists oil corrosion and vibration, and maintains leak-free performance. Strict testing guarantees seamless compatibility with the five Hyundai models and long-term hydraulic system stability

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 81881200/320-7346 DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW 81881200/320-7346 Disc is a core friction component for Caterpillar excavators (heavy-duty construction/mining use). It works with braking or transmission systems to generate controlled friction, ensuring reliable stopping or power transfer.

Meeting Caterpillar OEM standards (81881200/320-7346), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable friction performance.

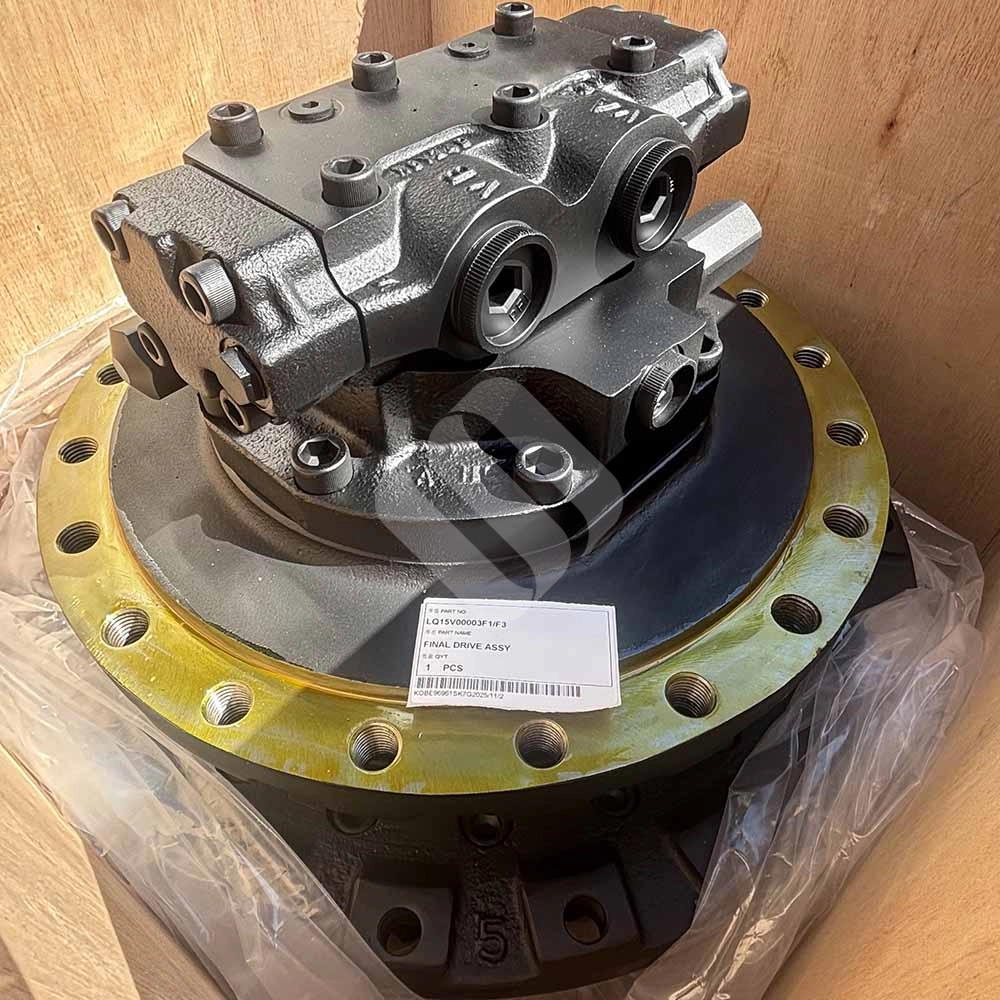

Final Drive Assy for Kobelco Excavator SK250NLC SK220LC SK250LC LQ15V00003F1 LQ15V00003F3 From SPARKLING MACHINERY

SPARKLING MACHINERY NEW SK250NLC SK220LC SK250LC LQ15V00003F1/F3 Final Drive Assy is a core power transmission component for 3 Kobelco excavator models (construction/mining use). It converts hydraulic energy to rotational force for track movement, ensuring stable traction during heavy-load tasks.

Meeting Kobelco OEM standards (dual part numbers), it resists -30°C to 100°C temps, high torque, and wear, guaranteeing seamless compatibility and long-term reliable driving performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879