SPARKLING R210W-9S Wheel Excavator Components

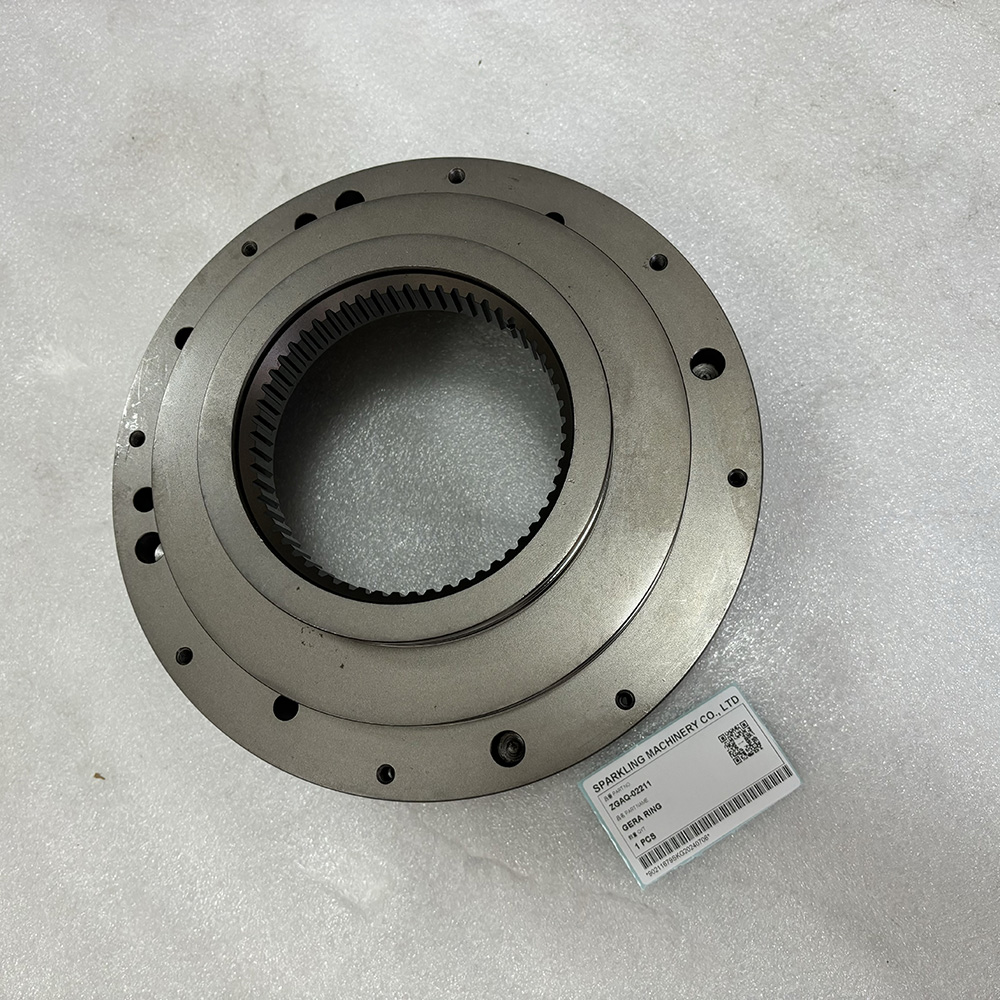

The ZGAQ-02211 Gear Ring and ZGAQ-02224 Carrier Planet are precision-engineered transmission components for Hyundai wheel excavator models R170W-7, R180W-9A, R200W-7, and R210W-9S. These parts are critical elements of the final drive assembly, responsible for delivering stable torque and efficient power transmission under heavy-duty working conditions.

Manufactured with high-strength alloy steel, both the gear ring and carrier planet are heat-treated for durability, ensuring long service life and excellent wear resistance in demanding excavation environments.

SPARKLING R210W-9S Wheel Excavator Components

SPARKLING MACHINERY proudly presents the R210W-9S wheel excavator components, engineered for unmatched reliability and precision. Since 2013, SPARKLING has dedicated itself to delivering high-quality excavator parts designed to meet the rigorous demands of modern construction and mining industries. Our R210W-9S wheel excavator components are manufactured with strict quality control to ensure stable performance in diverse working conditions.

Crafted with advanced technology and High Quality materials, these components guarantee durability and optimal functionality. Compatible with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, SPARKLING’s R210W-9S parts provide seamless integration and enhanced operational efficiency. Whether you need hydraulic components, undercarriage systems, engine parts, or electrical assemblies, SPARKLING offers customized solutions backed by expert technical support.

We believe in delivering not only superior products but also exceptional service, including meticulous consultation and continuous aftersales care. Our global sales network ensures timely delivery and reliable customer support worldwide, helping you reduce downtime and maintenance costs.

Choose SPARKLING MACHINERY for your R210W-9S wheel excavator components and experience the perfect balance of stability, precision, and perseverance. Trust in our commitment to quality and innovation — your peace of mind on every job site.

Detailed display

FAQ

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

ZGAQ-02211 Gear Ring ZGAQ-02224 Carrier Planet for Hyundai R170W-7 R200W-7 R210W-9S Excavator | Transmisson Parts | SPARKLING MACHINERY

The ZGAQ-02211 Gear Ring and ZGAQ-02224 Carrier Planet are precision-engineered transmission components for Hyundai wheel excavator models R170W-7, R180W-9A, R200W-7, and R210W-9S. These parts are critical elements of the final drive assembly, responsible for delivering stable torque and efficient power transmission under heavy-duty working conditions.

Manufactured with high-strength alloy steel, both the gear ring and carrier planet are heat-treated for durability, ensuring long service life and excellent wear resistance in demanding excavation environments.

SANY 14532878 Harness Assembly | SY330H SY305HC9I3KH.5.4B Wiring Harness | HARNESS ASSY for SANY Excavator

The SANY 14532878 Harness Assembly (HARNESS ASSY) is a high-quality electrical wiring component designed for SANY excavators, including models SY330H and SY305HC9I3KH.5.4B.

This harness assembly plays a critical role in the machine’s electrical system by securely transmitting signals and power between key components such as sensors, controllers, engine modules, and onboard displays. Designed to withstand the harsh environments of heavy-duty construction operations, it features durable insulation, corrosion-resistant terminals, and OEM-standard connectors for easy installation and long service life.

Whether you are conducting routine maintenance or replacing damaged wiring, this 14532878 wiring harness ensures optimal machine communication and electrical performance. It helps reduce downtime, prevent faults, and support efficient operation on the jobsite.

JCB Swing Gearbox Assembly for JS70, PC60-7 & PC70-7 Excavators – LNM0639

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

0006001 0006001H Wire Harness for HITACHI ZX200-3 ZX210K-3 ZX240-3 | Excavator Electrical Parts

The 0006001 / 0006001H Wire Harness is a high-quality electrical component specifically designed for HITACHI excavator models ZX200-3, ZX210H-3, ZX210K-3, and ZX240-3. This wire harness plays a vital role in ensuring the reliable transmission of electrical signals and power throughout the machine’s system, supporting essential functions such as sensors, engine management, lighting, and control units.

Engineered to meet OEM specifications, this harness features heat-resistant insulation, corrosion-resistant terminals, and precise connector layouts for plug-and-play compatibility. It offers outstanding durability and stable performance in harsh jobsite environments.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879