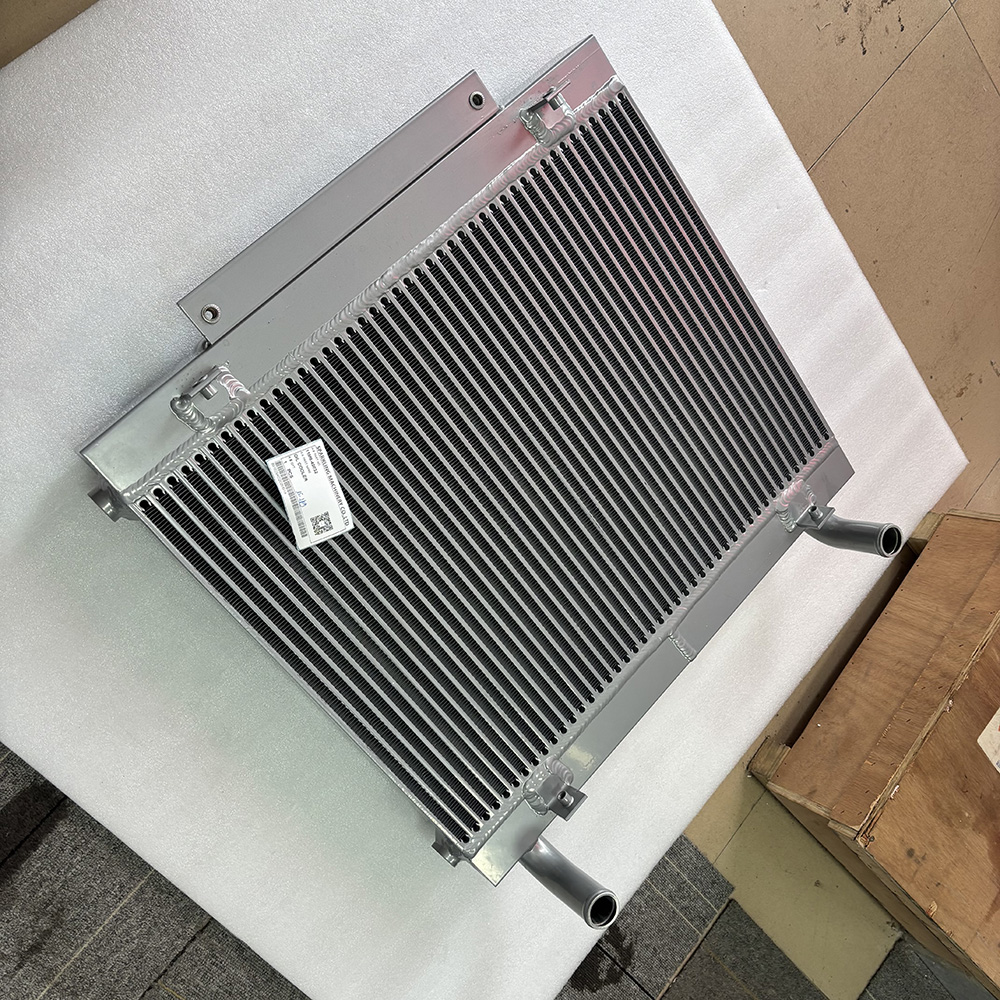

SPARKLING R55-7 Hydraulic Oil Cooler – Durable Excavator Part

The Hydraulic Oil Cooler Assembly (part no. 11M8‑40032 / 11M8‑43120) is a high-efficiency, all‑aluminum plate‑fin heat exchanger engineered for Hyundai compact excavators—specifically R55‑7 and R55W‑7 (also fitting R60‑7). Built free of epoxy, this OEM‑spec cooler ensures optimal heat dissipation and withstands continuous high pressure (up to 2 MPa), making it a reliable drop‑in replacement for demanding operation environments

The SPARKLING R55-7 hydraulic oil cooler is an essential component designed to keep your excavator’s hydraulic system running efficiently. Manufactured with precision and durability in mind, this cooler helps maintain optimal oil temperature, preventing overheating and ensuring smooth operation under heavy workloads.

Built to meet the high standards of the excavator industry, the R55-7 is compatible with popular brands such as Caterpillar, Komatsu, Hitachi, and Volvo. Its robust construction guarantees long service life, even in harsh working environments. By efficiently dissipating heat, it protects your hydraulic components, extending their lifespan and reducing costly downtime and repairs.

At SPARKLING MACHINERY, we are committed to delivering reliable and high-performance parts. Since 2013, our focus has been on quality, precision, and customer satisfaction. The R55-7 cooler not only boosts your equipment’s performance but also helps lower maintenance costs. We offer expert technical support and customization options to meet your unique needs, ensuring the best fit and function for your excavator.

Choose the SPARKLING R55-7 hydraulic oil cooler for dependable, stable cooling performance that enhances your excavator's productivity and longevity. Trust in our experience and global reputation to keep your machinery operating at peak efficiency.

Detailed display

Frequently Asked Questions

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Hyundai Oil Cooler Assy 11M8‑40032 / 11M8‑43120 for R55‑7 & R55W‑7 Excavators

The Hydraulic Oil Cooler Assembly (part no. 11M8‑40032 / 11M8‑43120) is a high-efficiency, all‑aluminum plate‑fin heat exchanger engineered for Hyundai compact excavators—specifically R55‑7 and R55W‑7 (also fitting R60‑7). Built free of epoxy, this OEM‑spec cooler ensures optimal heat dissipation and withstands continuous high pressure (up to 2 MPa), making it a reliable drop‑in replacement for demanding operation environments

401-00331 Final Drive Gearbox with Travel Motor for Doosan Daewoo S340LC-V S330LC-V

SPARKLING MACHINERY NEW S340LC-V 401-00331 Travel Reducer is a core power transmission component exclusively for Doosan S340LC-V excavators (heavy-duty construction/mining use). It reduces speed and amplifies torque for stable track movement, critical for heavy-load and rough-terrain operations.

Part number 401-00331 identifies a Final Drive Gearbox with Travel Motor (also referred to as a propel motor or travel device assembly) primarily used in heavy excavators.

Compatible Machines

This part is specifically designed for the following Doosan and Daewoo crawler excavator models:

Solar 340LC-V (S340LC-V)、Solar 330LC-V (S330LC-V)、Solar 340LC-7

Technical Specifications

Weight: 458kg

Components: Includes a complete assembly of the hydraulic travel motor and the gear reduction sections.

Alternative Part Numbers: This component may also be listed as 401-00331A, 401-00331B, or replace older numbers such as 2401-9264C and 170401-00027.

Tadano EXCAVATOR PARTS MADE IN CHINA NEW 363-811-25090 BRAKE PAD KIT,FRONT SPARKLING MACHINERY

SPARKLING MACHINERY NEW 363-811-25090 Front Brake Pad Kit is a critical safety component for Tadano excavators (widely used in construction, heavy lifting, and infrastructure projects). As the "front braking backbone", it generates friction with the front brake disc to decelerate or stop the excavator during on-site maneuvering—ensuring responsive braking for tasks like load positioning, slope navigation, and tight-space turning, while preventing front brake failure that risks equipment collisions or on-site accidents.

Meeting Tadano OEM standards (part no. 363-811-25090), it endures -30°C to 300°C braking temperatures, resists heat fading and wear, and maintains a stable friction coefficient. Strict testing guarantees seamless compatibility with applicable Tadano models and long-term front braking system reliability.

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW 306E 307E 308E 423-4562 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW 306E 307E 308E 423-4562 Solenoid Assy is a dedicated electrical control component for Caterpillar 306E, 307E, and 308E mini crawler excavators (versatile for landscaping, indoor demolition, and small-scale construction). As a key part of the excavator’s hydraulic or fuel system, it integrates solenoid and accessory components to convert electrical signals into mechanical action—controlling valve actuation or fuel flow to ensure precise operation of functions like bucket tilting and arm movement during delicate tasks.

Meeting Caterpillar OEM standards (part no. 423-4562), it endures -30°C to 85°C temperatures, resists vibration and electrical interference, and maintains stable switching performance. Strict testing guarantees seamless compatibility and long-term reliability for the three Caterpillar models.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879