SPARKLING Remanufactured Hydraulic Pump – Precision & Reliability

SPARKLING Remanufactured Hydraulic Pump – Precision & Reliability Guaranteed

SPARKLING MACHINERY, established in 2013, has built a solid reputation for delivering high-quality excavator parts with a focus on stability, precision, and perseverance. Our remanufactured hydraulic pump exemplifies these core values by offering exceptional performance and durability for your heavy machinery needs.

Crafted with stringent quality control processes, the SPARKLING remanufactured hydraulic pump is designed to fit seamlessly with excavators from leading brands like Caterpillar, Komatsu, Hitachi, and Volvo. Each pump undergoes a comprehensive remanufacturing process to restore it to near-original condition, ensuring reliable operation under even the most demanding working environments.

With SPARKLING’s hydraulic pump, customers benefit from a tailored solution backed by professional technical support and continuous service. Our commitment to innovation and altruism means not only competitive pricing but also a focus on reducing your operational costs without compromising quality. Whether you operate in construction, mining, or agriculture, our remanufactured hydraulic pumps provide optimal efficiency and longevity.

Choose SPARKLING for remanufactured hydraulic pumps that uphold the highest standards of precision and reliability. Trust in our expertise to keep your excavators running smoothly, backed by a global sales network and dedicated customer service. Experience peace of mind with components engineered for performance, durability, and cost-effectiveness.

Product Images

Question you may concern

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

HYUNDAI WHEEL LOADER HL770-7A HL770-9S 31LB-00400 HYDRAULIC MAIN PUMP ASSY

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC160C EC180C EC200B EC210B EC210C VOE22243151 CABLE HARNESS SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC160C EC180C EC200B EC210B EC210C VOE22243151 Cable Harness is a dedicated electrical connection component for VOLVO EC160C, EC180C, EC200B, EC210B, and EC210C crawler excavators (mid-sized equipment for construction, municipal engineering, and light mining). As the "nervous system" of the excavator, it transmits stable electrical signals between the control unit, sensors, and actuators, ensuring smooth operation of functions like engine start, hydraulic control, and instrument display during tasks like trench digging and material loading.

Meeting VOLVO OEM standards (part no. VOE22243151), it endures -30°C to 85°C temperatures, resists moisture and abrasion, and maintains signal integrity amid vibration. Strict testing guarantees seamless compatibility and long-term reliable performance for the five VOLVO models.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW205D EW210C EW210D EW230C VOE14603102/4472399046 PIN SPARKLING MACHINERY

SPARKLING MACHINERY NEW EW205D EW210C EW210D EW230C VOE14603102/4472399046 Pin is a key structural fastener for 4 Volvo wheeled excavator models (construction/municipal use). It secures movable components (e.g., arm hinges, bucket joints) to maintain alignment and withstand operational loads, ensuring stable mechanical performance.

Meeting Volvo OEM standards (VOE14603102/4472399046), it resists -30°C to 85°C temps, corrosion, and impact, guaranteeing seamless compatibility and long-term reliability.

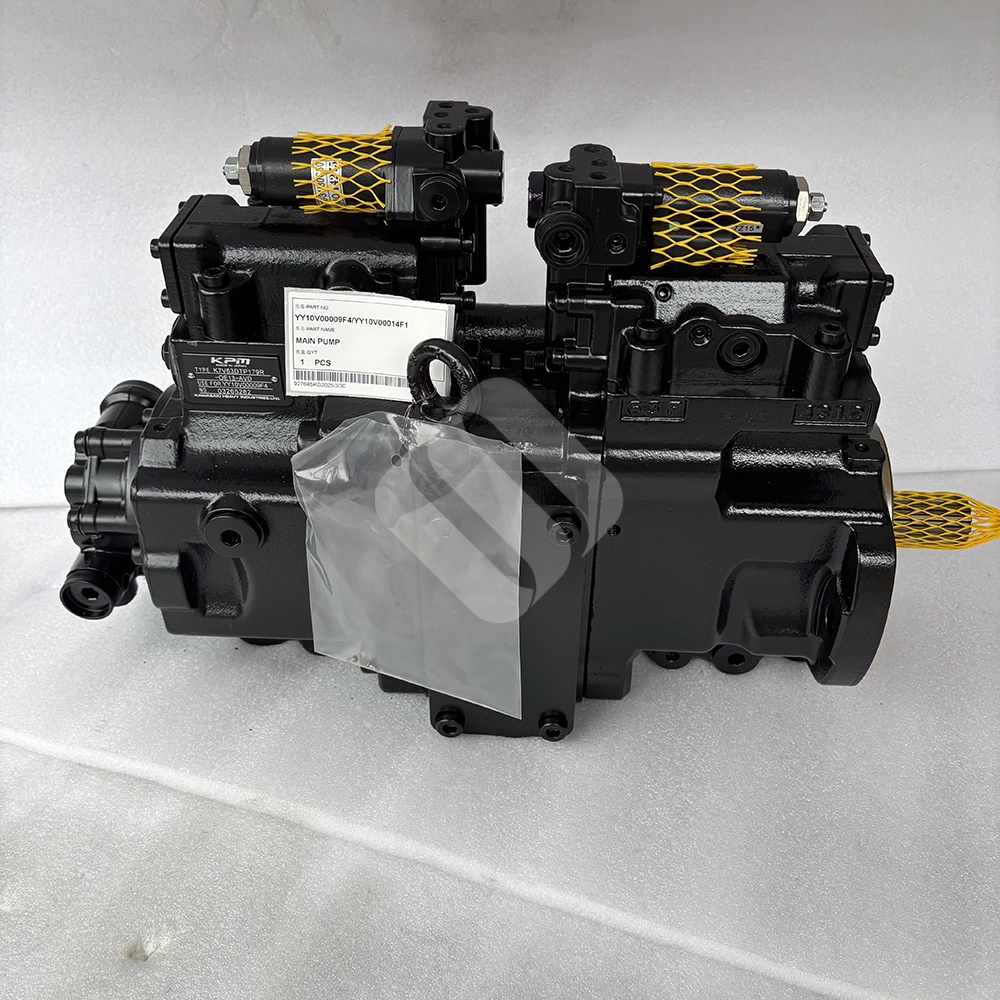

Excavator Spare Parts YY10V00009F4 YY10V00014F1 YY10V00009F1 YY10V00009F5 HYDRAULIC PUMP for Kobelco Construction Equipment Excavators SK140SRLC 140SR

The Made in China SPARKLING MACHINERY SK140SRLC/E135B Hydraulic Pump (Part Numbers: YY10V00009F4, YY10V00014F1, YY10V00009F1, YY10V00009F5) is a high-performance core component engineered for Kobelco SK140SRLC and E135B excavators. As the "heart" of the hydraulic system, it delivers consistent power transmission, ensuring smooth operation of lifting, digging, and rotating functions in heavy-duty construction scenarios. Crafted with premium materials and advanced manufacturing techniques, this pump withstands high pressure and harsh working conditions. Backed by SPARKLING’s strict quality standards, it minimizes leakage risks, reduces energy loss, and maximizes machine efficiency—your reliable choice for uninterrupted excavator performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879