SPARKLING Swing Motor Gearbox – Reliable Excavator Part

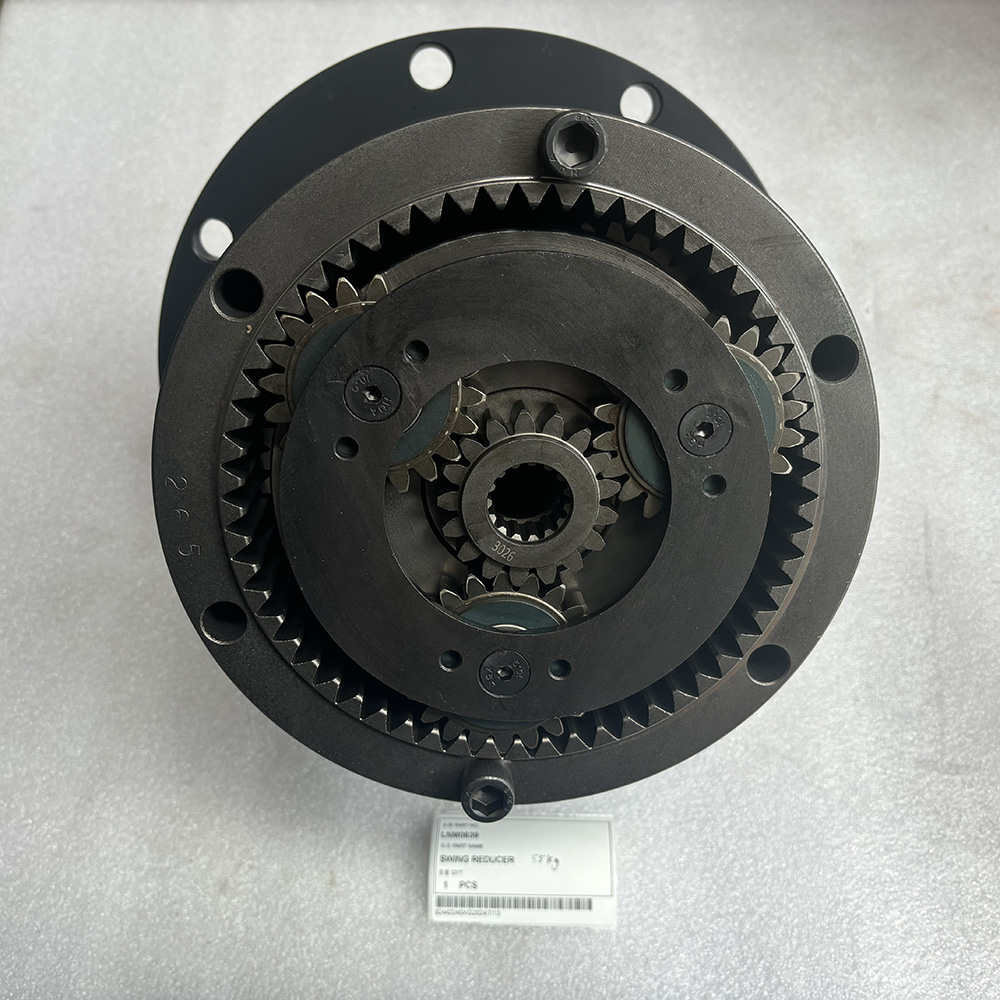

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

SPARKLING Swing Motor Gearbox: Precision, Power, and Reliability

SPARKLING MACHINERY, established in 2013, proudly presents its High Quality swing motor gearbox designed to meet the demanding needs of excavator operations. Engineered with unmatched precision and manufactured under strict quality control standards, the SPARKLING swing motor gearbox offers robust performance and long-lasting durability. Compatible with renowned excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, this gearbox seamlessly integrates with your machine to ensure smooth, efficient rotation and superior load handling.

Our swing motor gearbox is crafted to withstand extreme working conditions, maintaining stability and consistent output even during the most rigorous tasks. SPARKLING’s commitment to innovation and perseverance is evident in every component, guaranteeing you a dependable product that minimizes downtime and maximizes productivity.

At SPARKLING MACHINERY, we go beyond providing parts—we offer tailored solutions and technical support to fit your unique project requirements. Our expert consultation services and continuous after-sales care ensure peace of mind and enhanced operational efficiency.

Choose SPARKLING swing motor gearbox for a product backed by years of expertise, global reach, and a dedication to helping customers reduce costs without compromising quality. Trust SPARKLING MACHINERY as your reliable partner in excavator technology, advancing your business with stability, precision, and innovation.

Picture Show

Question you may concern

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

If you have any questions about our goods or services, please feel free to contact us.

JCB Swing Gearbox Assembly for JS70, PC60-7 & PC70-7 Excavators – LNM0639

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC250D EC250E EC300D EC300E 14604829 SHAFT SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC250D EC250E EC300D EC300E 14604829 Shaft is a dedicated power transmission component for VOLVO EC250D, EC250E, EC300D, and EC300E crawler excavators (heavy-duty equipment for mining, large-scale construction, and infrastructure projects). As a core part of the excavator’s hydraulic or undercarriage system, it transfers rotational power between gears, pumps, or track drives—ensuring smooth operation of critical functions like boom lifting, bucket digging, and track movement during high-intensity tasks.

Meeting VOLVO OEM standards (part no. 14604829), it endures high torque loads, -25°C to 100°C temperature fluctuations, and continuous vibration. It resists wear and corrosion, ensuring long-term reliable power transmission for the four VOLVO models, with strict testing guaranteeing seamless compatibility and stable performance.

24V HIGH-QUALITY 198-911-9240 RELAY for Komatsu Construction Equipment PC130-7 PC200-7 PC220-7 PC300-7 PC350-7 Wheel Excavator

The 24V HIGH-QUALITY 198-911-9240 RELAY is a premium electrical control component meticulously engineered for Komatsu Construction Equipment, specifically tailored to meet the reliable power switching demands of PC130-7, PC200-7, PC220-7, PC300-7, and PC350-7 Wheel Excavators. As a critical core of the machinery’s electrical system, this 24V relay functions as a high-performance switching device, precisely regulating electrical current flow to key auxiliary components (such as hydraulic pumps, lighting systems, wipers, and solenoids) in response to control signals.

Designed to seamlessly integrate with Komatsu’s -7 series wheel excavator electrical architecture, it delivers stable and consistent performance that safeguards the electrical system from overloads, prevents component damage, and ensures uninterrupted operation even in harsh construction environments.

Key Features

· 24V rated voltage optimized for perfect compatibility with Komatsu -7 series wheel excavator electrical systems

· Custom-engineered to match the exact specifications of Komatsu PC130-7, PC200-7, PC220-7, PC300-7, PC350-7 Wheel Excavators

· Fast signal response and high current-carrying capacity for reliable control of heavy-duty electrical loads

· Rugged, sealed housing design resistant to moisture, dust, vibration, and extreme temperature fluctuations

· Strict adherence to Komatsu OEM standards for seamless integration and consistent electrical performance

Compatible Models

· Komatsu Construction Equipment Wheel Excavators: PC130-7, PC200-7, PC220-7, PC300-7, PC350-7

Kubota HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW KX121 KX161 U45 RD118-69402 PUMP,GEAR SPARKLING MACHINERY

SPARKLING MACHINERY NEW KX121 KX161 U45 RD118-69402 Pump, Gear is a core hydraulic power component for Kubota KX121/KX161/U45 excavators (heavy-duty construction/mining use). It converts engine power into hydraulic pressure to drive actuators (arms, buckets), ensuring smooth operational movement.

Meeting Kubota OEM standards (RD118-69402), it resists -30°C to 100°C temps, pressure fluctuations, and wear, ensuring seamless compatibility and long-term reliable hydraulic power output.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879