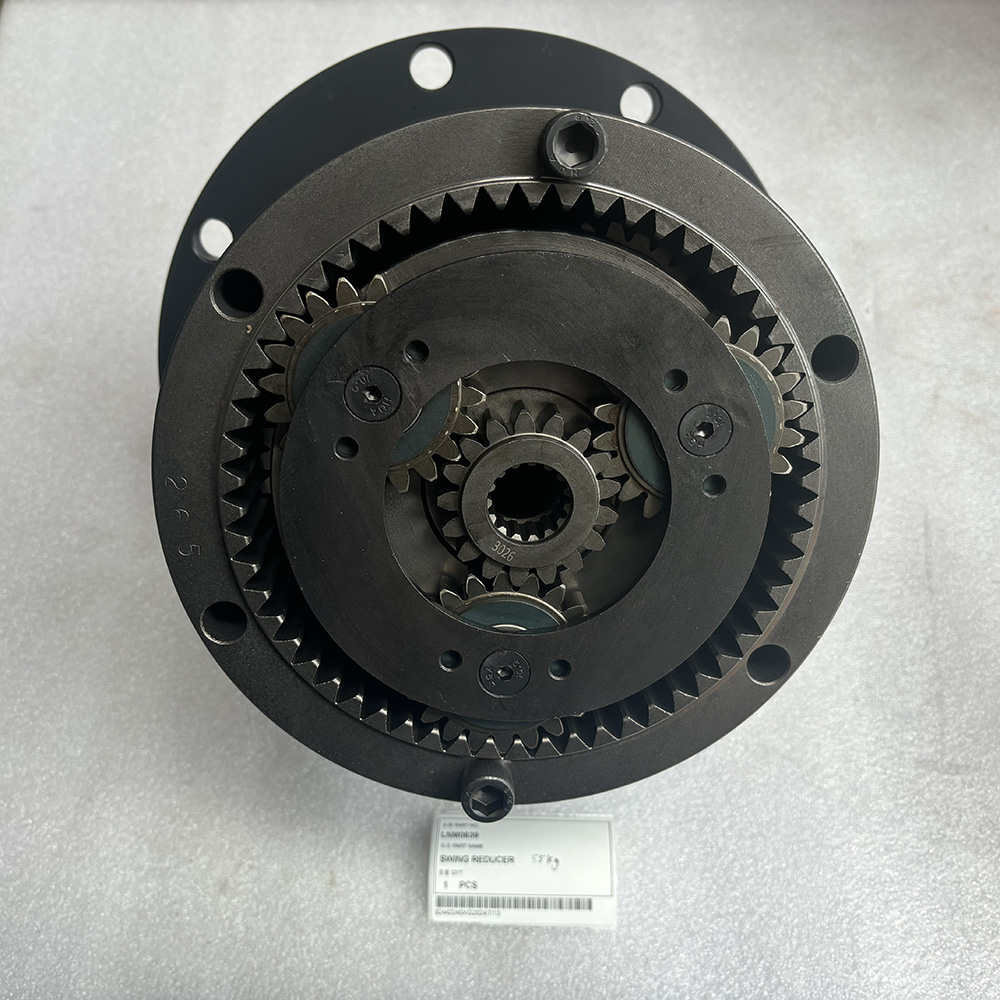

SPARKLING Swing Reducer Assembly – Durable & Precise Excavator Part

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

SPARKLING Swing Reducer Assembly – Precision and Durability for Your Excavator

Since 2013, SPARKLING MACHINERY has been a trusted name in the excavation industry, delivering high-quality excavator parts that guarantee stability, precision, and long-lasting performance. Our swing reducer assembly is expertly engineered to optimize your excavator’s swing mechanism, enhancing efficiency and reliability during operation.

Crafted using advanced manufacturing techniques and strict quality control, the SPARKLING swing reducer assembly provides smooth rotational motion and superior torque transmission. It is compatible with leading excavator brands, including Caterpillar, Komatsu, Hitachi, and Volvo, ensuring seamless fit and performance across different models. Whether working on heavy-duty projects or intricate tasks, our swing reducer assembly withstands rigorous working conditions, minimizing downtime and maintenance costs.

At SPARKLING MACHINERY, we emphasize innovation and customer-centric solutions. We offer customized configurations tailored to your specific machinery needs, combined with expert technical support and ongoing service to maximize your equipment’s life cycle. Our competitive pricing ensures you receive High Quality quality without compromise.

Choose SPARKLING’s swing reducer assembly to experience unmatched durability, precise engineering, and dependable service that keeps your excavator moving smoothly. Join thousands of satisfied customers worldwide who trust SPARKLING as their partner to reduce costs and boost productivity.

Elevate your excavator’s performance with SPARKLING MACHINERY — where quality meets innovation.

Picture Show

FAQ

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

About other questions pls contact me directily.

JCB Swing Gearbox Assembly for JS70, PC60-7 & PC70-7 Excavators – LNM0639

The JCB Swing Gearbox Assembly (suitable for JS70, PC60‑7, and PC70‑7/PC60‑7 excavators) is a precision-engineered swing reducer designed to deliver smooth and reliable rotational performance. Built to OEM standards (e.g., part no. LNM0639 / 201-26‑00130), this gearbox features hardened steel gears and robust bearings—ensuring durable operation under heavy load. It’s designed for easy drop-in replacement and reduces maintenance downtime. Ideal for construction, demolition, and excavation applications.

Excavator Spare Parts 8.3 Kg ME990328/60289472 WATER PUMP for Mitsubishi Engine 4M50 4M50T Excavators Sany SY215C KATO HD820-V-5

SPARKLING MACHINERY New Water Pump (ME990328/60289472) is a critical cooling system component for heavy-duty construction machinery (excavators, loaders included). As the core of the coolant circulation system, it drives coolant through radiators and engine blocks to transfer excess heat, maintaining the engine’s optimal operating temperature (82–95°C). This prevents overheating during high-intensity tasks, safeguarding engine power, fuel efficiency and long service life.

Function: This mechanical water pump is driven by the engine belt system and circulates coolant through the engine to prevent overheating.

Construction: The pump features a robust metal construction with a quality seal to ensure leak-resistant performance and durability.

Condition: Available as new aftermarket or OEM replacement parts, designed to meet original equipment specifications for a direct fit.

Compatible Engines and Equipment:

Engines: Mitsubishi 4M50 and 4M50T diesel engines.

Excavators:

Sany SY215C

KATO HD820-V-5

Sumitomo SH60-2

Mitsubishi Fuso (some models)

Planet Carrier 423-22-32662 for Komatsu Wheel Loader WA380-5 WA380-6 WA430-5 WA400-5 WA380-7 WA380-8

The 423-22-32662 planet carrier is a durable transmission component designed for Komatsu wheel loaders WA380-5, WA380-6, WA430-5, WA400-5, WA380-7, and WA380-8. It supports planetary gears and ensures stable torque transmission, reliable drivetrain performance, and long service life under heavy-duty working conditions.

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 6675-31-1011 CRANKSHAFT

SPARKLING MACHINERY NEW 6675-31-1011 Crankshaft is a critical power transmission component tailor-made for compatible heavy-duty diesel engines used in excavators, loaders, and industrial machinery. As the "rotational core" of the engine, it converts the reciprocating motion of pistons into continuous rotational torque, which drives the machinery’s hydraulic systems, undercarriage, and working mechanisms. This function is essential for delivering consistent power to support heavy-duty tasks like deep digging, large-volume material lifting, and continuous mining operations.

Designed to meet original equipment performance standards, it maintains stable operation even under extreme conditions—including high rotational speeds, intense mechanical loads, and temperature fluctuations. It ensures smooth torque transfer with minimal vibration, preventing premature wear of engine components and safeguarding long-term operational efficiency. Backed by strict performance verification, it guarantees reliable power output to minimize engine downtime and keep heavy machinery running continuously.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879