SPARKLING Swing Reducer Replacement – Durable Excavator Parts

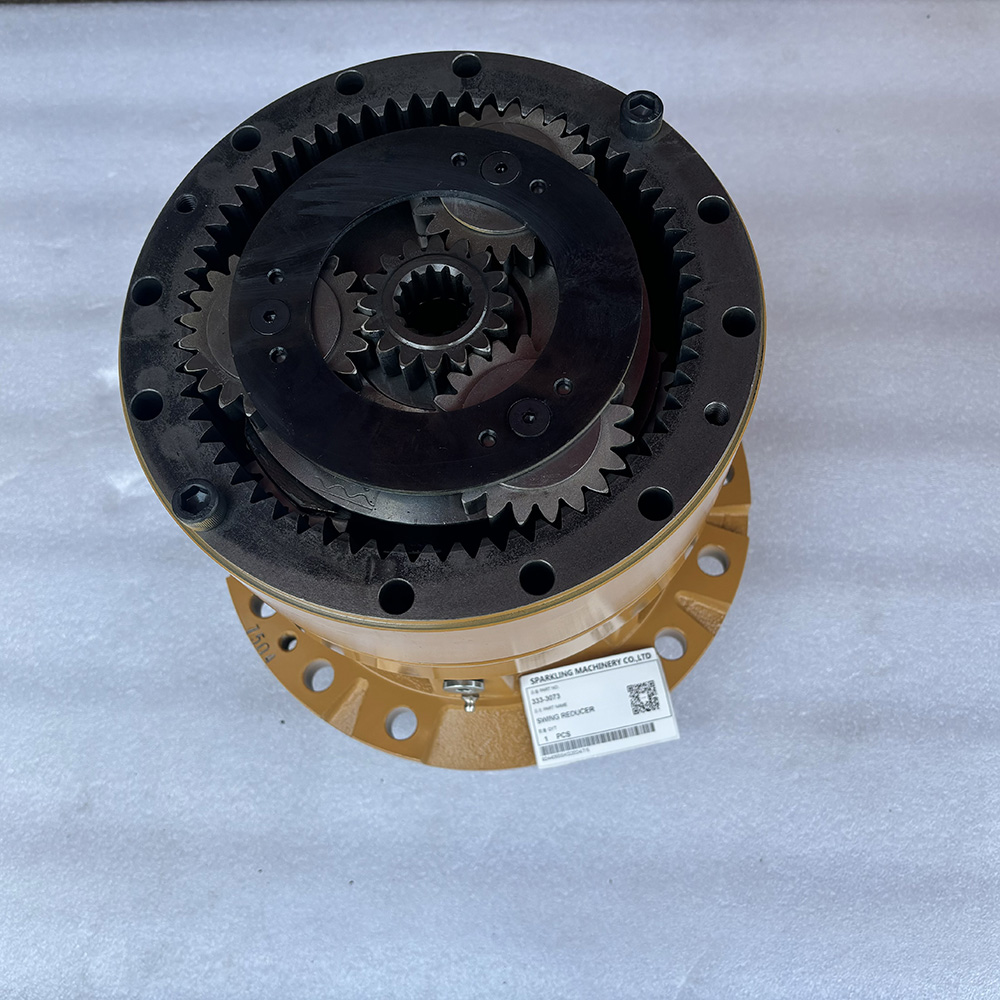

The Caterpillar Swing Reducer (Part No. 333‑3073 / 3333073) is a premium swing gearbox designed to restore smooth and powerful 360° rotation in CAT excavators—compatible with 312D, 312DL, 312D2, 312E, 313D, 313D2, 314C, and 314E models.

It features hardened steel planetary gears, sealed bearings, and robust housing to handle heavy-duty rotational loads while preventing leaks and contamination . Available as genuine OEM or high-quality aftermarket units, this swing reducer ensures a direct-fit replacement and optimized machine performance.

The SPARKLING swing reducer replacement is designed to keep your excavator performing at its best. Manufactured with precision and engineered for durability, this component plays a crucial role in the smooth rotation of your excavator’s upper structure. Whether you operate Caterpillar, Komatsu, Hitachi, Volvo, or other leading brands, our swing reducer offers perfect compatibility and reliable performance.

Founded in 2013, SPARKLING MACHINERY has focused on providing high-quality excavator parts that withstand tough working conditions. Our swing reducers undergo strict quality control to ensure stability and precision, helping reduce downtime and maintenance costs. This replacement part is built to last, ensuring your excavator runs efficiently and safely even in the most demanding environments.

We understand that excavator parts are critical to your business, so we provide full technical support and customized solutions to meet your specific needs. With competitive pricing and a global sales network, SPARKLING MACHINERY is dedicated to delivering products that increase your equipment’s lifespan while optimizing your investment.

Choose SPARKLING swing reducer replacement for a dependable, cost-effective solution that supports your excavator’s peak performance, backed by years of industry expertise and customer-focused service.

Product Images

Frequently Asked Questions

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

CATERPILLAR EXCAVATOR 312D L 312C 313D2 GC 313D2 333-3073 3333073 SWING REDUCER

The Caterpillar Swing Reducer (Part No. 333‑3073 / 3333073) is a premium swing gearbox designed to restore smooth and powerful 360° rotation in CAT excavators—compatible with 312D, 312DL, 312D2, 312E, 313D, 313D2, 314C, and 314E models.

It features hardened steel planetary gears, sealed bearings, and robust housing to handle heavy-duty rotational loads while preventing leaks and contamination . Available as genuine OEM or high-quality aftermarket units, this swing reducer ensures a direct-fit replacement and optimized machine performance.

KOMATSU MADE IN CHINA SPARKLING MACHINERY NEW 334/C2147 RADIATOR

SPARKLING MACHINERY NEW 334/C2147 Radiator is a critical cooling system component tailored for compatible heavy-duty construction machinery, such as excavators and loaders. As the core of the machinery’s heat dissipation system, it efficiently transfers heat from engine coolant to the surrounding air—preventing engine overheating during high-intensity operations like prolonged digging, heavy-load lifting, and continuous idling in construction, mining, or infrastructure projects. This function is vital for maintaining the engine’s optimal operating temperature (typically 82–95°C), which directly influences fuel efficiency, power output, and the long-term service life of key engine components.

Engineered to match original equipment performance standards, it retains strong heat dissipation efficiency even under harsh working conditions, including high ambient temperatures, dust accumulation, and constant machinery vibration. It resists coolant leakage and internal blockages, avoiding cooling system failures that could lead to costly engine damage or unplanned downtime. Backed by strict performance verification, it guarantees reliable heat exchange to support uninterrupted operation of compatible heavy-duty machinery.

Komatsu EXCAVATOR PARTS MADE IN CHINA NEW HB205 HB215 PC200 PC200LL PC210 PC220 708-2L-07710 VALVE ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW HB205 HB215 PC200 PC200LL PC210 PC220 708-2L-07710 Valve Assy is a dedicated hydraulic control assembly for Komatsu HB205, HB215, PC200, PC200LL, PC210, and PC220 crawler excavators (widely used in construction, mining, and infrastructure projects). As the "hydraulic control hub", it integrates multiple valves to regulate oil flow, pressure, and direction—powering key functions like boom lifting, bucket digging, and swing movements, ensuring smooth, precise operation during high-intensity tasks while maintaining system stability.

Meeting Komatsu OEM standards (part no. 708-2L-07710), it endures 30 MPa working pressure, -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and ensures leak-free performance. Strict testing guarantees seamless compatibility with the six Komatsu models and long-term hydraulic system reliability.

119005-77051 Intake Air Heater for Komatsu Equipment CK20-1 CK25-1 SK1020-5 | Construction Machinery Spare Parts

The 119005-77051 Intake Air Heater is a core cold-start component for Yanmar 4TNV94 engines in Komatsu skid steers CK20-1, CK25-1, and loader SK1020-5. It preheats intake air to ensure reliable cold starts, smooth idle, and reduced emissions in low-temperature conditions, critical for consistent operation of construction machinery.

Function: This component is powered by the vehicle's battery and designed to heat the incoming air charge, which facilitates faster starts, reduces white smoke (cold emissions), and minimizes engine wear during ignition in chilly conditions.

Compatible Engines and Equipment:

· Yanmar Engines: 4TNV94L, 4TNV98, 4TNE88, and 4TNV98T series diesel engines.

· Komatsu Engines: 4D94E and 4D94LE engines.

· Komatsu Equipment: CK20-1, CK25-1, SK1020-5, SK1026-5, and PC80MR-3.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879