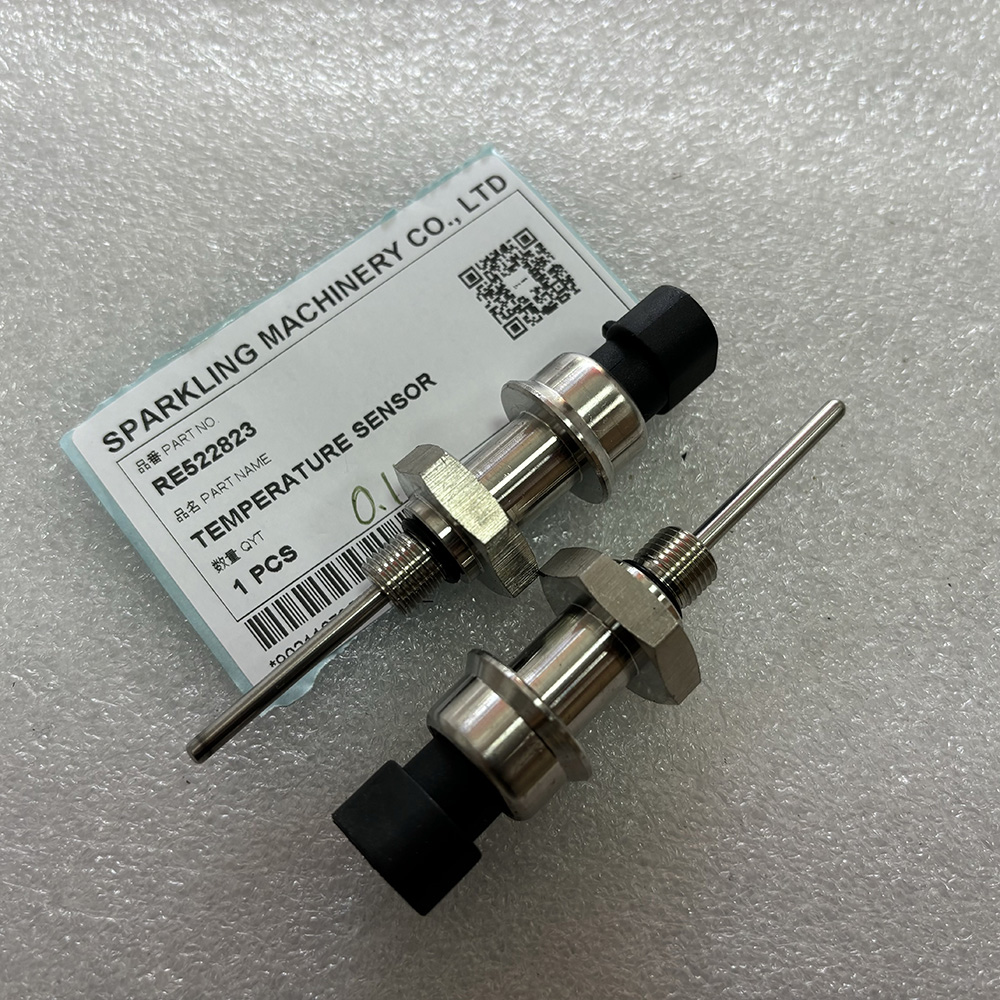

SPARKLING Temperature Sensor – Precision Excavator Monitoring

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

SPARKLING Temperature Sensor – Precision and Reliability for Excavators

Since 2013, SPARKLING MACHINERY has been a leader in delivering high-quality excavator parts, dedicated to stability, precision, and perseverance. Our SPARKLING temperature sensor exemplifies our commitment to excellence, engineered to provide accurate, real-time temperature monitoring in demanding excavator environments.

Designed to withstand harsh conditions, the SPARKLING temperature sensor integrates seamlessly with major brands like Caterpillar, Komatsu, Hitachi, and Volvo. Its advanced sensing technology ensures optimal engine temperature management, preventing overheating and enhancing machinery performance. By maintaining precise temperature control, SPARKLING temperature sensors contribute to extended engine life, reduced downtime, and improved operational efficiency.

What sets our sensor apart is the rigorous quality control applied throughout the manufacturing process. Every unit is tested to meet strict standards, guaranteeing durability and consistent performance across diverse working conditions. Additionally, SPARKLING MACHINERY provides tailored technical support and consultation, enabling customers to find the perfect fit for their excavator fleets.

Our competitive pricing strategy ensures that you receive superior products without compromising your budget, helping you reduce operational costs while maintaining the highest quality standards. Supported by a global sales network, SPARKLING MACHINERY is more than just a supplier; we are your reliable partner committed to innovation and customer satisfaction.

Upgrade your excavator’s performance with SPARKLING temperature sensors—engineered for precision, built for endurance.

Product Image

Question you may concern

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

About other questions pls contact me directily.

John Deere Temperature Sensor RE522823 – Fits 1210E • 670G • 290GLC • 755D • 624K • 350DLC • 953M

The John Deere Temperature Sensor (RE522823) is a vital engine and hydraulic monitoring component for mid-to-large John Deere equipment—optimizing operational safety across models like the 1210E, 670G, 290GLC, 755D, 624K, 350DLC, and 953M. Engineered for precise temperature measurement, this two-terminal sensor ensures accurate data feedback to prevent overheating and protect critical engine components. Built to meet or exceed OEM standards, it delivers reliable performance in rugged environments.

Excavator Spare Parts 0.1KG 2566454 TEMPERATURE SENSOR for Caterpillar Equipment M313D M315D M316D

SPARKLING MACHINERY New Temperature Sensor (2566454) is a precision monitoring component dedicated to 312E, 320E and 324E excavators. As a core part of the engine and hydraulic system monitoring, it real-time detects coolant and hydraulic oil temperatures, and transmits accurate signals to the control panel. This prevents overheating during heavy-duty operations, ensures stable engine power, protects hydraulic components from thermal damage, and avoids unplanned downtime.

Function: Measures the temperature of the engine coolant or air inlet manifold to help maintain optimal engine operating conditions and ensure proper function of the engine control unit (ECU).

Material/Design: Features a durable brass or high-quality stainless steel body and a sealed, standard blade-style electrical connector designed for tough working conditions.

Specifications:

Thread Size: M18-1.5.

Overall Length: Approximately 1.81 inches (46 mm).

Cross Reference: This part can also cross-reference with the Perkins part number T407354.

Compatible Caterpillar Engines and Equipment:

Engines: C4.4, C6.6, C7, C7.1, C9, C9.3, C13, C15, C18.

Excavators: M313D, M315D, M316D, M318D, M322D, 312E, 312E L, 314E CR, 314E LCR, 316E L, 318E L, 320E, 320E L, 329E, 323F SA.

Generators: LC51XX, LC31XX.

Other Machinery: Wheel tractor-scrapers, wheel skidders, asphalt compactors, and mini hydraulic excavators (e.g., 304, 305).

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 23527830 OIL TEMPERATURE SENSOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW 23527830 Oil Temperature Sensor is a core monitoring component for Volvo excavators (construction/mining use). It accurately detects hydraulic or engine oil temperature, transmitting real-time data to prevent overheating damage.

Meeting Volvo OEM standards (23527830), it resists -30°C to 120°C temps, oil corrosion, and electrical interference, ensuring seamless compatibility and reliable long-term temperature monitoring performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879