SPARKLING Wheel Excavator Shaft China

The ZGAQ-01370 Input Shaft is a high-performance replacement component specifically designed for the Hyundai R200W-7 Wheel Excavator. It plays a critical role in transmitting torque from the engine or transmission to the working components of the drivetrain.

Manufactured in China under strict quality control, this input shaft is built with high-grade alloy steel, offering excellent wear resistance, precision machining, and outstanding durability under heavy-duty operation. Weighing just 2KG, it provides optimal strength without unnecessary weight, making it an ideal fit for your excavator’s power system.

Discover the exceptional quality of the wheel excavator shaft China by SPARKLING MACHINERY, a leader in excavator parts since 2013. Our wheel excavator shafts are engineered with precision and durability to meet the rigorous demands of heavy-duty construction and mining equipment. Compatible with major excavator brands including Caterpillar, Komatsu, Hitachi, and Volvo, SPARKLING’s shafts ensure seamless performance and long-lasting reliability.

At SPARKLING MACHINERY, we prioritize stability and perseverance, implementing strict manufacturing protocols and comprehensive quality control. This commitment guarantees that every wheel excavator shaft is crafted to withstand challenging working conditions, minimizing downtime and maintenance costs for our customers. Our extensive experience enables us to provide customized solutions and expert technical support, ensuring each part integrates perfectly with your machinery.

Trusted worldwide, SPARKLING stands for professionalism and reliability. Our competitive pricing structure does not compromise quality, allowing businesses to optimize their operations cost-effectively. Backed by a global sales network and continuous after-sales service, SPARKLING MACHINERY is your dependable partner for excavator parts.

Choose SPARKLING’s wheel excavator shaft China for unmatched quality, expert support, and peace of mind on every project.

Detailed display

Q&A

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

If you have any questions or concern, please contact us.

HYUNDAI WHEEL EXCAVATOR R200W-7 ZGAQ-01370 SHAFT-INPUT CHINA MADE SPARKLING MACHINERY 2KG

The ZGAQ-01370 Input Shaft is a high-performance replacement component specifically designed for the Hyundai R200W-7 Wheel Excavator. It plays a critical role in transmitting torque from the engine or transmission to the working components of the drivetrain.

Manufactured in China under strict quality control, this input shaft is built with high-grade alloy steel, offering excellent wear resistance, precision machining, and outstanding durability under heavy-duty operation. Weighing just 2KG, it provides optimal strength without unnecessary weight, making it an ideal fit for your excavator’s power system.

Excavators Spare Parts 150106-00133B COVER for Doosan Construction Equipment D24 DX57W-5 D20S-7 D25S-7 D30S-7 D33S-7

The Excavators Spare Parts 150106-00133B COVER is a premium protective component for Doosan D24/DX57W-5/D20S-7/D25S-7/D30S-7/D33S-7. It shields internal parts from hazards, ensures structural reinforcement, and seamlessly integrates with Doosan’s system for stable performance in harsh construction environments.

Key Features

· Custom-tailored for target Doosan construction equipment models

· Protective design to block dust, debris, and mechanical impact

· Reinforced structure to enhance equipment rigidity

· Precision-contoured for seamless fit and unobstructed heat dissipation

· Compliant with Doosan OEM specifications for consistent integration

Compatible Models

· Doosan Construction Equipment: D24, DX57W-5, D20S-7, D25S-7, D30S-7, D33S-7

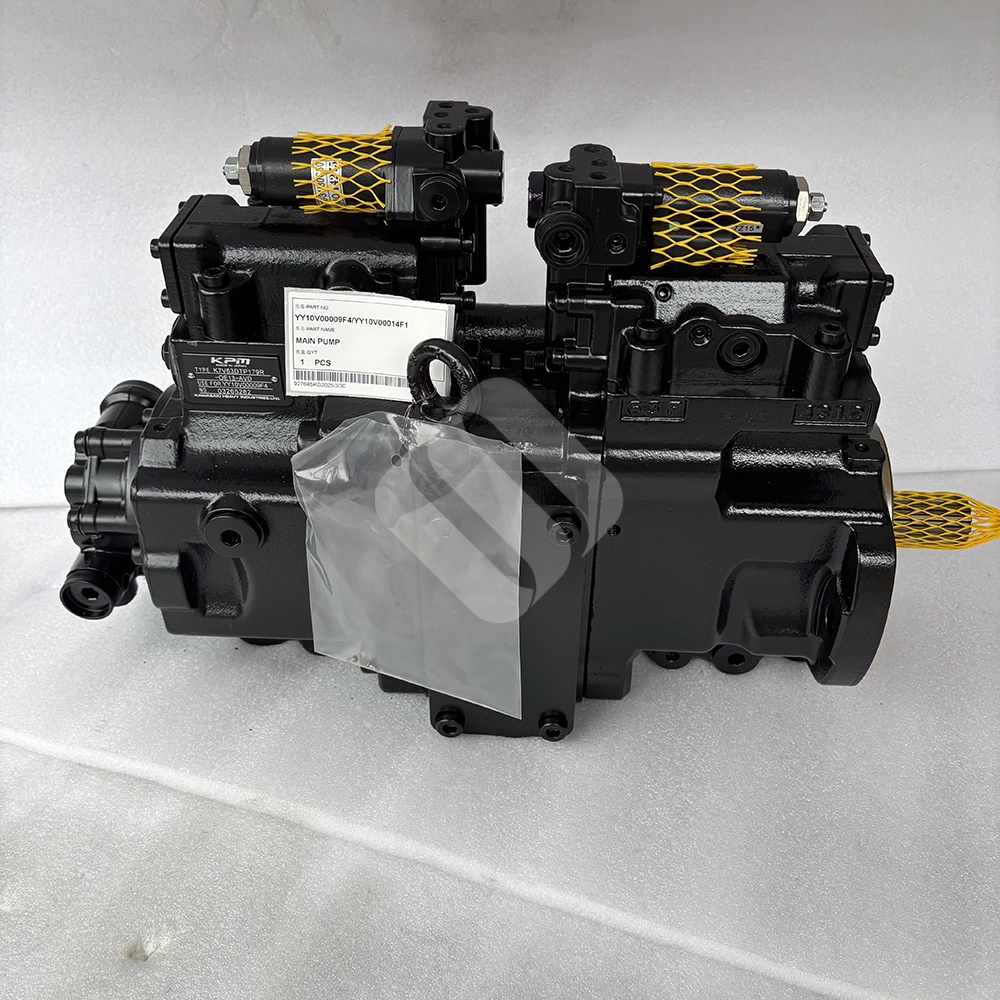

Excavator Spare Parts YY10V00009F4 YY10V00014F1 YY10V00009F1 YY10V00009F5 HYDRAULIC PUMP for Kobelco Construction Equipment Excavators SK140SRLC 140SR

The Made in China SPARKLING MACHINERY SK140SRLC/E135B Hydraulic Pump (Part Numbers: YY10V00009F4, YY10V00014F1, YY10V00009F1, YY10V00009F5) is a high-performance core component engineered for Kobelco SK140SRLC and E135B excavators. As the "heart" of the hydraulic system, it delivers consistent power transmission, ensuring smooth operation of lifting, digging, and rotating functions in heavy-duty construction scenarios. Crafted with premium materials and advanced manufacturing techniques, this pump withstands high pressure and harsh working conditions. Backed by SPARKLING’s strict quality standards, it minimizes leakage risks, reduces energy loss, and maximizes machine efficiency—your reliable choice for uninterrupted excavator performance.

Construction Machinery Spare Parts 8.8Kg 6215-11-5140 Exhaust Manifold For Komatsu Engines Sa12v140 Saa12v140e-3a And Wa900-3 Wheel Loaders

SPARKLING MACHINERY New Exhaust Manifold (6215-11-5140) is a dedicated engine exhaust component for EGS1000, EGS1050 and EGS1200 heavy-duty machinery (generators, construction equipment included). As a core part of the exhaust system, it collects exhaust gas from engine cylinders and channels it efficiently into the exhaust pipe, ensuring smooth gas flow and optimal engine backpressure. This preserves engine power, cuts fuel consumption and helps meet emission standards during high-load operations.

· Engine Compatibility - Komatsu engines:SA12V140 and SAA12V140E-3A models.

· Machine Compatibility - heavy machinery:D475A-3, D475A-5, HD985-3, HD985-5 dump trucks, and WA900-3 wheel loaders.

· More: EGS1000, EGS1050, EGS1200

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879