SPARKLING YF30V00011F3 - Reliable Excavator Hydraulic Component

Precision Hydraulic Control Valve for E235BSR Series Crawler Excavators

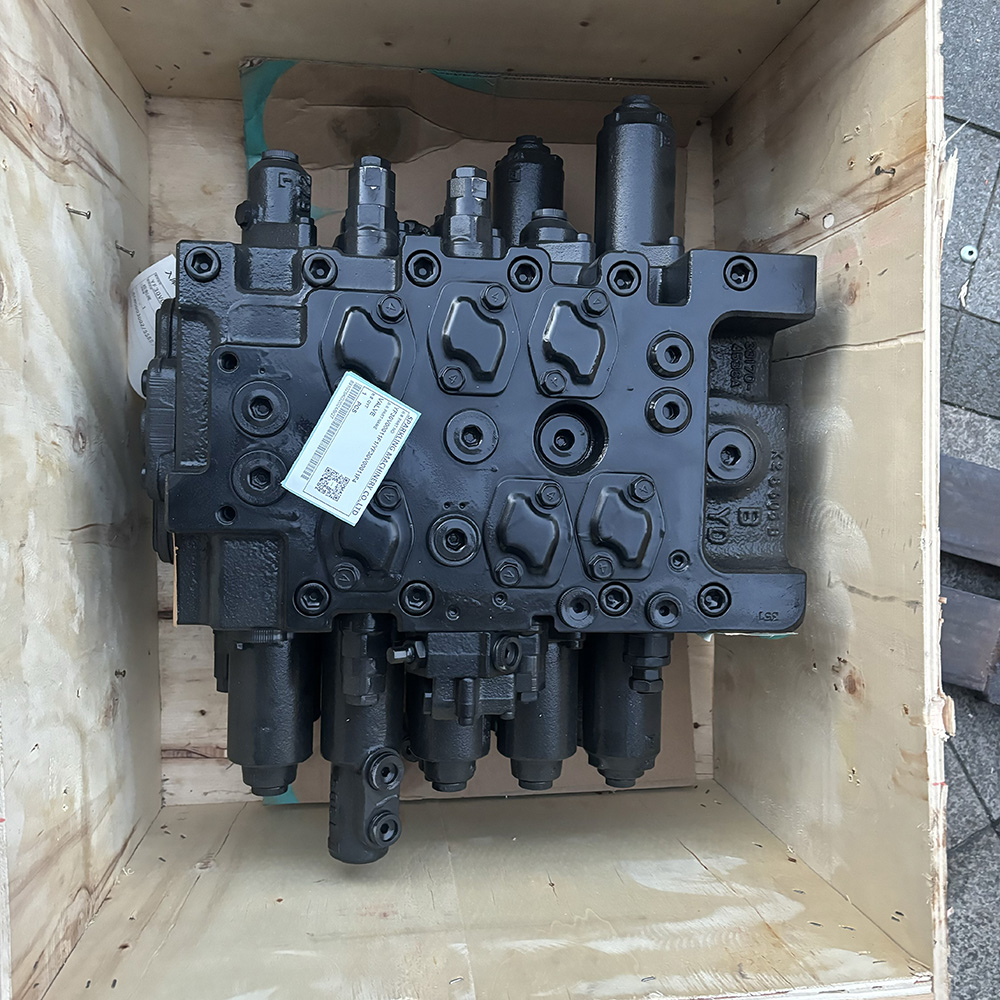

Engineered for E235BSR, E235BSRLC, and E235BSRNLC crawler excavators, the Hydraulic Control Valve (YF30V00011F1/F3/F4) is the intelligent nerve center of your machine’s hydraulic system. This OEM-compatible valve integrates advanced flow distribution and pressure regulation technologies, enabling seamless coordination of multiple actuators (boom, arm, swing, travel) under heavy loads. Featuring hardened spools with laser-etched metering profiles and triple-layer Nitrile seals6, it minimizes internal leakage, reduces heat generation, and eliminates sudden pressure drops during complex compound operations. Rigorously tested to exceed 500,000 cycles at 350 bar4, SPARKLING MACHINERY’s valve ensures precise controllability in demanding applications – from trenching to lifting – while extending pump life by stabilizing system pressure fluctuations.

SPARKLING YF30V00011F3 Excavator Part – Precision and Reliability You Can Trust

Since its founding in 2013, SPARKLING MACHINERY has built a reputation for excellence in the excavator parts industry. The YF30V00011F3, a flagship hydraulic component from SPARKLING, embodies the company’s commitment to stability, precision, and long-lasting performance. Designed for compatibility with industry-leading brands such as Caterpillar, Komatsu, Hitachi, and Volvo, this part ensures seamless integration and superior functionality.

Manufactured under strict quality control processes, the YF30V00011F3 provides dependable operation even in the most challenging environments. Whether used in heavy-duty construction or intensive excavation projects, this component delivers consistent power and efficiency. At SPARKLING, every product undergoes rigorous testing to meet the highest standards, giving you confidence in its durability and performance.

Beyond product quality, SPARKLING MACHINERY offers tailored solutions and expert technical support. Our dedicated consultation services help you select the right parts to optimize your machinery, reduce downtime, and lower operational costs. With a global sales network and continuous after-sales service, SPARKLING is your reliable partner throughout the lifecycle of your excavator parts.

Choosing the YF30V00011F3 means investing in excellence, innovation, and comprehensive support. Trust SPARKLING MACHINERY to keep your equipment running at peak performance with parts designed for stability and precision.

Product Images

Frequently Asked Questions

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

CRAWLER EXCAVATORS E235BSR E235BSRLC E235BSRNLC YF30V00011F1 YF30V00011F3 YF30V00011F4 HYDRAULIC CONTROL VALVE

Precision Hydraulic Control Valve for E235BSR Series Crawler Excavators

Engineered for E235BSR, E235BSRLC, and E235BSRNLC crawler excavators, the Hydraulic Control Valve (YF30V00011F1/F3/F4) is the intelligent nerve center of your machine’s hydraulic system. This OEM-compatible valve integrates advanced flow distribution and pressure regulation technologies, enabling seamless coordination of multiple actuators (boom, arm, swing, travel) under heavy loads. Featuring hardened spools with laser-etched metering profiles and triple-layer Nitrile seals6, it minimizes internal leakage, reduces heat generation, and eliminates sudden pressure drops during complex compound operations. Rigorously tested to exceed 500,000 cycles at 350 bar4, SPARKLING MACHINERY’s valve ensures precise controllability in demanding applications – from trenching to lifting – while extending pump life by stabilizing system pressure fluctuations.

CATERPILLAR MADE IN CHINA SPARKLING MACHINERY NEW 312E 320E 324E 329E 3576475 FUEL TRANSFER PUMP

SPARKLING MACHINERY NEW 312E 320E 324E 329E 3576475 Fuel Transfer Pump is a dedicated fuel system component exclusively designed for 312E, 320E, 324E, and 329E excavators. As the core of the excavators’ fuel supply chain, it efficiently transfers fuel from the fuel tank to the engine’s injection system—ensuring a steady, pressure-stable fuel flow to support optimal combustion during heavy-duty operations like construction digging, mining loading, and infrastructure maintenance. This function is vital for maintaining consistent engine power output, preventing fuel starvation (which causes sudden power drops or stalling), and protecting the injection system from damage due to insufficient fuel supply.

Engineered to match original equipment performance standards, it maintains reliable fuel transfer efficiency even under harsh working conditions, including extreme temperatures (-30°C to 80°C), continuous excavator vibration, and exposure to fuel contaminants or construction site dust. It resists fuel leakage and internal component wear, avoiding fuel system failures that could lead to costly engine repairs or unplanned downtime. Backed by strict performance verification, it guarantees consistent fuel delivery to support uninterrupted operation of 312E/320E/324E/329E excavators.

Caterpillar EXCAVATOR PARTS MADE IN CHINA NEW E320GC E323D E326GC E330GC E336GC E349GC 485-5747 SOLENOID VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW E320GC E323D E326GC E330GC E336GC E349GC 485-5747 Solenoid Valve is a core hydraulic control component for Caterpillar E320GC, E323D, E326GC, E330GC, E336GC, and E349GC excavators (widely used in construction, mining, and large-scale infrastructure projects). As the "hydraulic flow switch", it regulates the on/off and direction of hydraulic oil flow—controlling key functions like boom lifting, bucket digging, and arm movement during high-intensity tasks, while ensuring responsive and precise operation to avoid hydraulic system misalignment.

Meeting Caterpillar OEM standards (part no. 485-5747), it endures -30°C to 95°C temperatures, resists hydraulic oil corrosion and vibration, and guarantees leak-free and stable electromagnetic control. Strict testing ensures seamless compatibility with the six Caterpillar models and long-term hydraulic system reliability.

HIGH-QUALITY 22B-54-16221 HANDLE for KOMATSU Construction Equipment PC45MR PC55MR PC78US PC78UU PC88MR PC138 PC228US Excavator

The HIGH-QUALITY 22B-54-16221 HANDLE is a premium operational component meticulously engineered for KOMATSU Construction Equipment, specifically tailored to meet the precise control needs of PC45MR, PC55MR, PC78US, PC78UU, PC88MR, PC138, and PC228US excavators. As a critical part of the machinery’s operator control system, this handle delivers responsive, ergonomic operation, enabling precise manipulation of excavator functions while ensuring comfort during long working hours. It is designed to seamlessly integrate with KOMATSU’s excavator control architecture, guaranteeing consistent performance that enhances operational efficiency and operator experience.

Key Features

· Custom-engineered for perfect compatibility with KOMATSU PC45MR, PC55MR, PC78US, PC78UU, PC88MR, PC138, PC228US excavators

· Ergonomic design with optimized grip texture and contour for reduced operator fatigue during extended use

· High-strength, wear-resistant material construction for durability in harsh construction environments

· Precision-machined connection points for secure installation and responsive control feedback

· Strict adherence to KOMATSU OEM specifications for seamless integration and reliable performance

Compatible Models

· KOMATSU Construction Equipment Excavators: PC45MR, PC55MR, PC78US, PC78UU, PC88MR, PC138, PC228US

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879