SPARKLING YN35V00052F2 Excavator Part – High-Quality & Durable

The Kobelco Solenoid Valve (part no. YN35V00054F1 / YN35V00052F2) is a precision-engineered hydraulic control valve designed for mid-to-large Kobelco excavators. Compatible with popular models like SK295‑9, SK350‑9, SK260‑9, SK210‑9, SK210‑8, SK140SRLC, and more, this valve delivers accurate pressure regulation, responsive hydraulic actuation, and robust performance under heavy workload conditions. Built to OEM-quality specifications with high-grade materials, it ensures long-lasting reliability and seamless drop-in replacement for both genuine and aftermarket options.

SPARKLING YN35V00052F2 Excavator Part – Precision and Durability You Can Trust

Introducing the YN35V00052F2, a High Quality excavator part from SPARKLING MACHINERY, a leader in high-quality excavator components since 2013. Engineered with exceptional precision and durability, this part exemplifies SPARKLING’s commitment to stability, performance, and long-lasting service. Designed to meet the demanding needs of heavy machinery, the YN35V00052F2 seamlessly integrates with a broad range of excavator systems, including hydraulic, electrical, and undercarriage configurations.

SPARKLING MACHINERY’s rigorous manufacturing process ensures that each YN35V00052F2 part maintains superior workmanship, meeting strict quality controls that guarantee flawless operation in the toughest environments. Compatible with industry giants like Caterpillar, Komatsu, Hitachi, and Volvo, this part offers unparalleled reliability and versatility for your machinery.

What sets the YN35V00052F2 apart is not just its High Quality quality but also SPARKLING's commitment to customer satisfaction. The company offers customized solutions tailored to your specific needs, expert technical support, and ongoing consultation, helping you optimize performance while reducing costs.

Choose SPARKLING’s YN35V00052F2 excavator part for a combination of advanced engineering, affordability, and trusted service. With a global network, SPARKLING MACHINERY stands as your dependable partner in enhancing excavator efficiency and longevity. Invest in the YN35V00052F2 and experience the assurance of a part built for excellence.

Product Image

Q&A

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Kobelco Solenoid Valve YN35V00054F1 / YN35V00052F2 – Fits SK295‑9, SK350‑9, SK260‑9 & More

The Kobelco Solenoid Valve (part no. YN35V00054F1 / YN35V00052F2) is a precision-engineered hydraulic control valve designed for mid-to-large Kobelco excavators. Compatible with popular models like SK295‑9, SK350‑9, SK260‑9, SK210‑9, SK210‑8, SK140SRLC, and more, this valve delivers accurate pressure regulation, responsive hydraulic actuation, and robust performance under heavy workload conditions. Built to OEM-quality specifications with high-grade materials, it ensures long-lasting reliability and seamless drop-in replacement for both genuine and aftermarket options.

DX140W DX140W-3 DX140W-5 DX170W-5 DX190W-3 1.430-00026 1430-00026 1430-00026 GEAR SHIFT SYSTEM

The 1.430-00026 Gear Shift System is a vital transmission component designed for DOOSAN wheeled excavators, including models DX140W, DX140W-3, DX140W-5, DX170W-5, and DX190W-3. This gear shifting system ensures smooth and reliable transmission performance under various operating conditions, enabling your equipment to adapt seamlessly to job site demands.

Manufactured to meet or exceed OEM standards, this replacement unit by SPARKLING MACHINERY delivers exceptional durability, accurate shifting response, and easy installation—perfect for keeping your DOOSAN machine operating at peak performance.

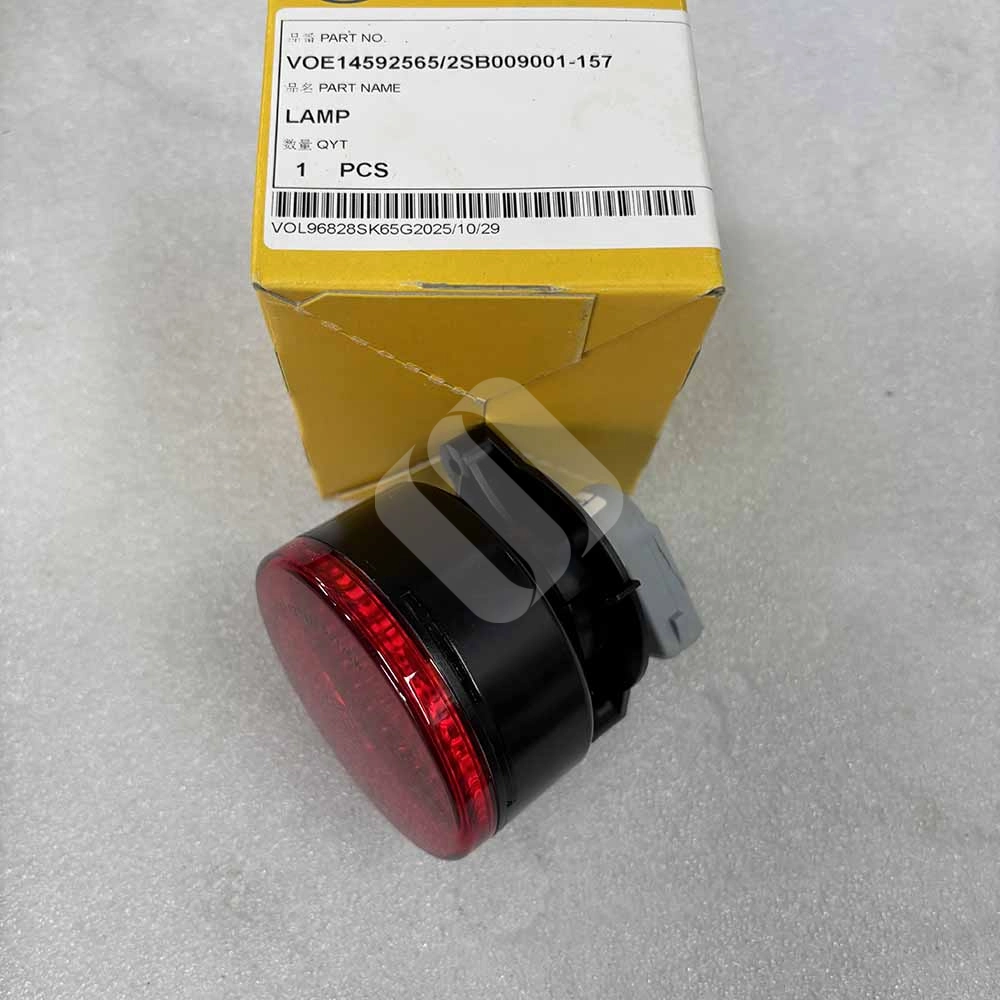

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW140C EW145B EW160C EW180C VOE14592565/2SB009001-157 LAMP SPARKLING MACHINERY

SPARKLING MACHINERY NEW EW140C EW145B EW160C EW180C VOE14592565 2SB009001-157 Lamp is a critical lighting component for 4 Volvo excavator models (construction/municipal use). It delivers bright, stable illumination for work areas—essential for low-light/nighttime operations—to ensure operator visibility and safety.

Meeting Volvo OEM standards (VOE14592565 & 2SB009001-157), it resists -30°C to 85°C temps, moisture, and vibration, guaranteeing seamless compatibility and long-term reliable performance.

Construction Equipment Spare Parts 0.8kg Ya00030724 Monitor For Hitachi Excavators Zx70 Zx110

SPARKLING MACHINERY New Monitor (YA00030724) is a premium China-made HMI component for construction machinery (excavators, loaders, bulldozers included). As the central information hub of the control system, it displays real-time operational data (engine speed, hydraulic pressure, fuel level, coolant temperature, fault codes) and allows operators to adjust settings and access diagnostics. This keeps operators updated on machinery status, enabling timely adjustments to prevent failures and ensure efficient, safe operation in construction, mining and earthmoving tasks.

Function: Provides a clear LCD display and flexible keys for better machine control and monitoring.

Compatible Models: Hitachi ZX70, ZX110, ZX120-3, ZX120-5G, ZX200-1, ZX200-3G, ZX330, and ZX360 excavators.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879