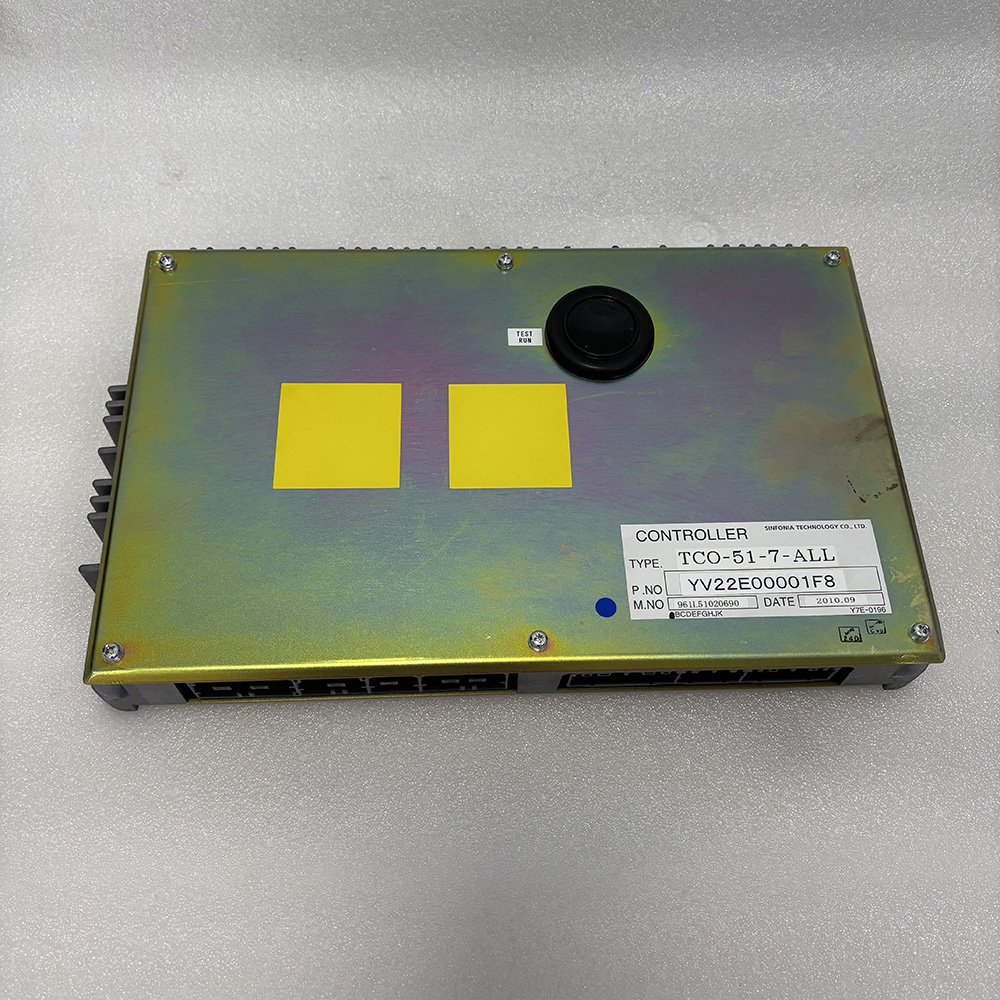

SPARKLING YV22E00001F8 ECU – Reliable Excavator Control Unit

The YV22E00001F8 / YV22E00001F5 CPU Controller Unit is an original electronic control module designed specifically for KOBELCO excavators SK115SR and SK135SR. As the central brain of your machine’s electronic system, this controller ensures precise management of engine, hydraulic, and diagnostic systems, helping maintain peak performance and fuel efficiency.

Manufactured with high reliability standards, this OEM-grade controller unit is pre-programmed and ready for plug-and-play installation. It delivers accurate operational feedback, error detection, and optimized machine responsiveness, making it a critical replacement part for professional excavator maintenance.

SPARKLING YV22E00001F8 ECU – Precision Control for Your Excavator

Discover the SPARKLING YV22E00001F8 ECU, engineered to elevate the performance and reliability of your excavator. As a vital electrical control unit, this ECU ensures precise management of engine and hydraulic functions, optimizing efficiency and reducing downtime. Manufactured with SPARKLING MACHINERY’s commitment to stability, precision, and perseverance, the YV22E00001F8 ECU is compatible with leading brands such as Caterpillar, Komatsu, Hitachi, and Volvo, assuring seamless integration and dependable operation.

At SPARKLING, founded in 2013, every product undergoes rigorous quality control to withstand diverse working environments. The YV22E00001F8 ECU stands out for its robust design, consistent performance, and ability to enhance excavator responsiveness. We also provide tailored technical support and solutions to help you achieve maximum productivity.

Choosing SPARKLING means you receive more than an excavator part; you gain a trusted partner dedicated to reducing your maintenance costs through durable and affordable solutions. Our global sales network ensures prompt delivery and after-sales service, so you always feel supported.

Upgrade your excavator’s functionality today with the YV22E00001F8 ECU from SPARKLING. Performance, reliability, and care combined for your peace of mind.

Product Images

Q&A

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

KOBELCO EXCAVATOR SK115SR SK135SR YV22E00001F8 YV22E00001F5 CPU CONTROLLER UNIT ORIGINAL

The YV22E00001F8 / YV22E00001F5 CPU Controller Unit is an original electronic control module designed specifically for KOBELCO excavators SK115SR and SK135SR. As the central brain of your machine’s electronic system, this controller ensures precise management of engine, hydraulic, and diagnostic systems, helping maintain peak performance and fuel efficiency.

Manufactured with high reliability standards, this OEM-grade controller unit is pre-programmed and ready for plug-and-play installation. It delivers accurate operational feedback, error detection, and optimized machine responsiveness, making it a critical replacement part for professional excavator maintenance.

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 350 594-7756 TURBO SPARKLING MACHINERY

SPARKLING MACHINERY NEW 350 594-7756 Turbo is a core engine performance component exclusively for Caterpillar 350 excavators (heavy-duty construction/mining use). It boosts air intake pressure to enhance combustion efficiency and maximize engine power output.

Meeting Caterpillar OEM standards (594-7756), it resists up to 850°C high temps, high pressure, and wear, ensuring seamless compatibility and long-term reliable engine performance.

Excavator Spare Parts VOE20450742 PULLY for Volvo Construction Equipment EC210 EC210B EC240B EC290 EW140B

The Excavator Spare Parts VOE20450742 PULLY is a premium power transmission component tailored for Volvo EC/EW-series equipment. It ensures smooth belt operation, delivers stable torque transfer, integrates seamlessly with target models, and maintains durability in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo EC210/EC210B/EC240B/EC290/EW140B

· Precision-machined groove design for secure belt engagement and minimal slippage

· High load-bearing capacity to withstand heavy-duty power transmission demands

· Wear-resistant and corrosion-proof for long-lasting performance in outdoor conditions

· Strict adherence to Volvo OEM specifications for consistent functionality

Compatible Models

· Volvo Construction Equipment: EC210, EC210B, EC240B, EC290, EW140B

VOE14616866 / 14400789 Hose for Volvo EC140B EC160B EC180B | Excavator Spare Parts

SPARKLING MACHINERY NEW EC140B EC160B EC180B VOE114616866/14400789 Hose is a dedicated flexible fluid transmission component for VOLVO EC140B, EC160B, and EC180B crawler excavators (widely used in construction, municipal engineering, and medium-scale earthmoving projects). As a key part of the excavator’s hydraulic or cooling system, it enables seamless transfer of hydraulic oil or coolant between moving and fixed components (e.g., hydraulic cylinders, pumps, radiators)—ensuring uninterrupted fluid flow during tasks like digging, loading, and road grading.

- Compatible Equipment: These hoses are a direct fit for several models, including the Volvo EC140B, EC160B, and EC180B excavators.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879