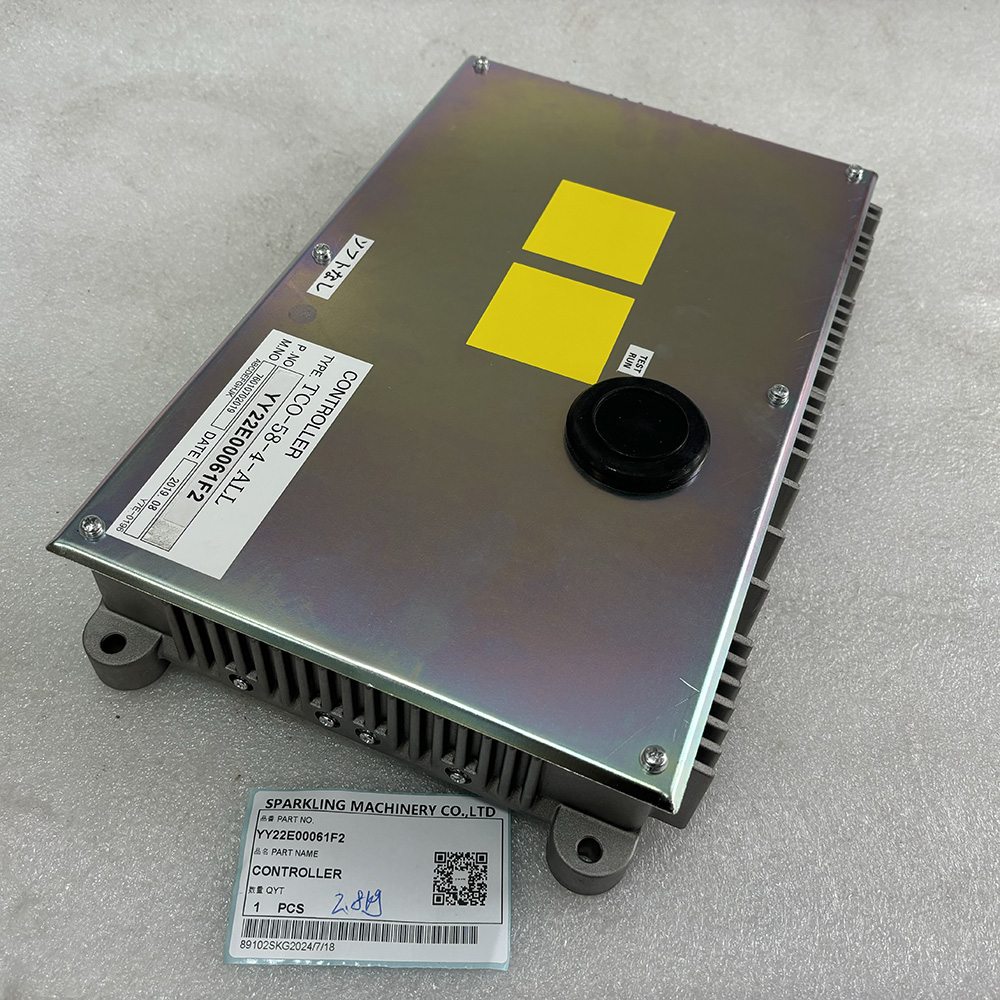

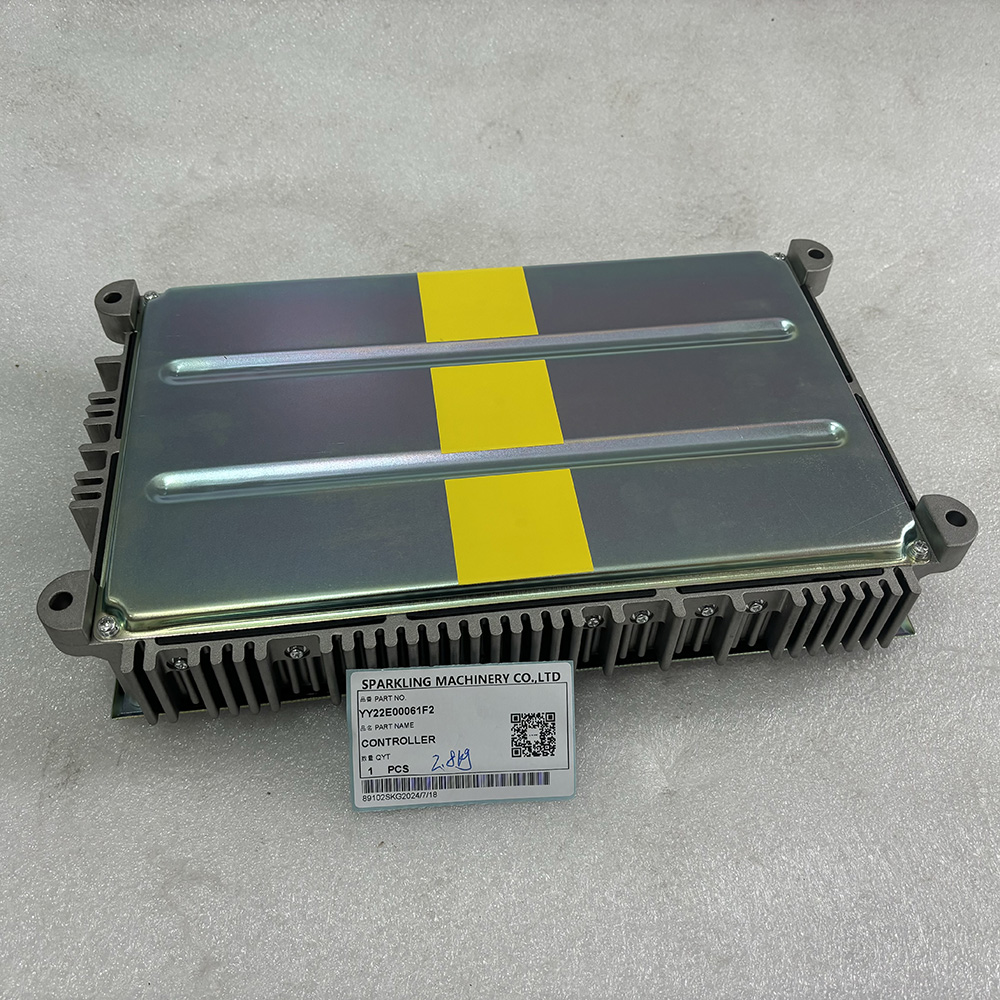

SPARKLING YY22E00061F1 - Durable Excavator Hydraulic Component

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

Discover the YY22E00061F1 hydraulic component by SPARKLING, a trusted choice for excavator efficiency and durability. Manufactured by SPARKLING MACHINERY—a leader in high-quality excavator parts since 2013—this product embodies precision engineering and reliable performance. Designed to seamlessly fit with leading excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, the YY22E00061F1 ensures optimal functionality across diverse working environments.

SPARKLING’s commitment to stability and perseverance means every YY22E00061F1 component undergoes rigorous quality control to withstand the toughest conditions, minimizing downtime and maximizing productivity. Whether you operate in construction, mining, or landscaping, this hydraulic part supports smooth, efficient machine operation, ly reducing maintenance costs and extending excavator lifespan.

Backed by SPARKLING’s global sales network and expert technical support, customers receive tailored solutions and meticulous consultations to ensure the perfect fit for their machinery. Our competitive pricing policy doesn’t compromise on quality, reflecting our core values of altruism and innovation, and helping you get more value for your investment.

Choose YY22E00061F1 from SPARKLING and experience a product designed with your needs in mind—durable, precise, and built to keep your equipment running at its best.

Product Image

Frequently Asked Questions

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

E135SRLC E135SR Control Unit YY22E00061F1 F2 F5 F6 | Excavator ECU ECM Module | SPARKLING MACHINERY

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

Kubota EXCAVATOR PARTS MADE IN CHINA NEW KX033 KX040 KX057 KX12 RD411-51122 CAP SPARKLING MACHINERY

SPARKLING MACHINERY NEW KX033 KX040 KX057 KX12 RD411-51122 Cap is a key protective component for 4 Kubota excavator models (construction/municipal use). It seals fluid reservoirs (oil, coolant) or access ports, preventing leakage, dust ingress, and component corrosion. Meeting Kubota OEM standards (RD411-51122), it resists -30°C to 85°C temps, oil, and UV damage, ensuring seamless compatibility and long-term protection.

Hitachi HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW ZX70-3 ZX75UR-3 ZX75US-3 4668185 RADIATOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW ZX70-3 ZX75UR-3 ZX75US-3 4668185 Radiator is a core cooling component for 3 Hitachi excavator models (construction/mining use). It dissipates engine heat efficiently to maintain optimal operating temperatures, critical for heavy-load durability.

Meeting Hitachi OEM standards (4668185), it resists -30°C to 120°C temps, dust, and corrosion, ensuring seamless compatibility and long-term reliable thermal management performance.

Excavators Spare Parts 720-2M-13412 CAM, ROCKER for Komatsu Construction Equipment D31EX-21 D31PX-21 D37EX-21 D37PX-21 D39EX-21 D39PX-21

The Excavators Spare Parts 720-2M-13412 CAM, ROCKER is a core valve train component for Komatsu D31EX-21/D31PX-21/D37EX-21/D37PX-21/D39EX-21/D39PX-21. It ensures precise valve timing, delivers stable performance under heavy loads, and seamlessly integrates with Komatsu’s engine system in harsh construction environments.

Key Features

· Custom-tailored for target Komatsu -21 series construction equipment

· Precision-machined profile for accurate valve actuation and synchronization

· High wear resistance to withstand prolonged engine operation

· Stable performance under high temperature and mechanical stress

· Compliant with Komatsu OEM specifications for seamless integration

Compatible Models

· Komatsu Construction Equipment: D31EX-21, D31PX-21, D37EX-21, D37PX-21, D39EX-21, D39PX-21

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879