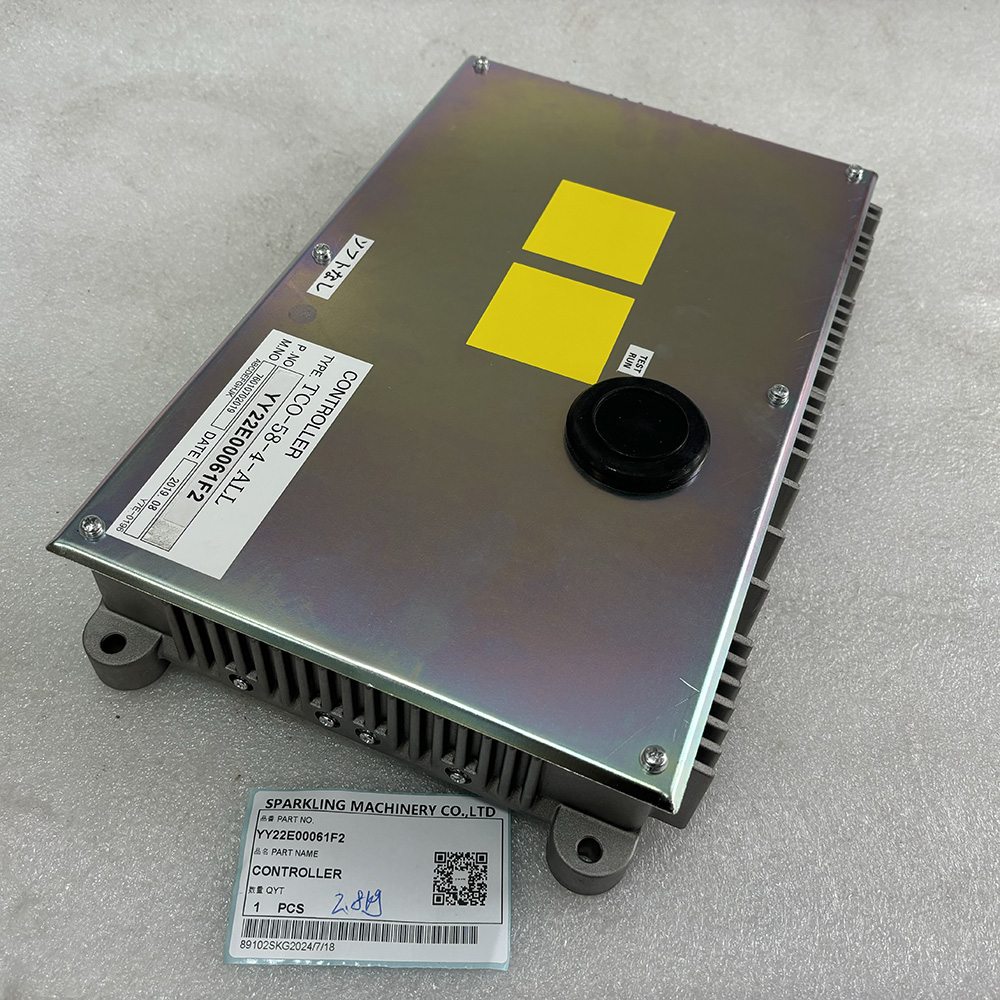

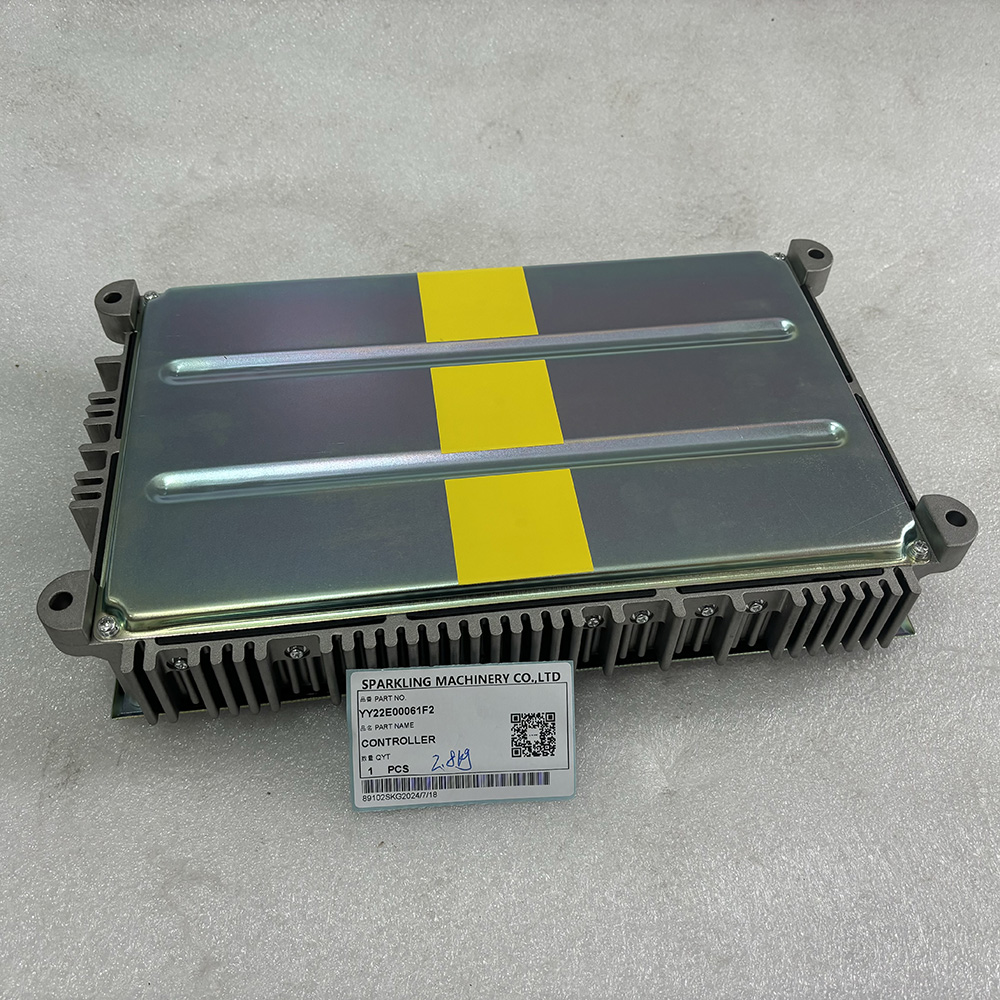

SPARKLING YY22E00061F6 - High Quality Excavator Part for Reliable Performance

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

Introducing the SPARKLING YY22E00061F6 – a premier excavator component designed to elevate your machinery’s performance. As part of SPARKLING MACHINERY’s extensive lineup, this high-precision part embodies the brand’s commitment to stability, durability, and cutting-edge engineering, making it an essential choice for heavy-duty operations.

Since 2013, SPARKLING MACHINERY has been a leader in producing high-quality excavator parts, including hydraulic components, undercarriage systems, engine parts, electrical components, cabs, mini excavators, and accessories. The YY22E00061F6 product is engineered for compatibility with globally renowned brands such as Caterpillar, Komatsu, Hitachi, and Volvo, ensuring seamless integration and peak performance across various machines.

Crafted with rigorous manufacturing standards and stringent quality control procedures, the YY22E00061F6 guarantees long-lasting reliability even under the most challenging working conditions. This part is ideal for operators seeking precision and endurance, backed by SPARKLING’s technical expertise and customized solutions.

SPARKLING MACHINERY not only offers competitively priced products but also provides comprehensive technical support and personalized consultation, helping customers optimize their equipment lifecycle and reduce maintenance costs. With a worldwide sales network and a steadfast vision to be the leading excavator parts manufacturer globally, SPARKLING is your trusted partner in enhancing construction productivity.

Experience superior quality, innovation, and service with the SPARKLING YY22E00061F6 – where performance meets reliability.

Detailed display

FAQ

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

If you have another questions, please feel free to contact us.

E135SRLC E135SR Control Unit YY22E00061F1 F2 F5 F6 | Excavator ECU ECM Module | SPARKLING MACHINERY

The YY22E00061F1 / F2 / F5 / F6 Control Unit is an essential electronic component designed for use in New Holland Kobelco E135SRLC and E135SR excavators. This control unit is responsible for managing the excavator’s core electronic systems, including engine, hydraulic functions, and machine diagnostics, ensuring optimal performance and operational efficiency.

This series of controllers is known for its fast data processing, stable communication, and durable circuit design that can withstand the tough environments excavators operate in.

Construction Equipment Spare Parts 24v 11q6-90040 Compressor Assy For Hyundai Excavators Hw140 Hw160 Hw210 Case Wheel Loaders 1221e And 1221f

SPARKLING MACHINERY NEW R210-7 R220-7 R250-7 R290-7 R305-7 R335-7 11Q6-90040 Compressor Assy is a dedicated air conditioning core component for Hyundai R210-7, R220-7, R250-7, R290-7, R305-7, and R335-7 crawler excavators (widely used in construction, mining, and infrastructure projects). As the "cooling power source" of the excavator cab, it compresses refrigerant to maintain stable temperature control—ensuring a comfortable operating environment for operators during long-hour tasks in high-temperature or harsh weather.

Compatible Equipment Models:

· Hyundai Excavators: HW140, HW160, HW210, HX140L, HX160L, HX180L, R140LC-9, R210LC-9, R250LC-9, and others in the 7 and 9 series.

· Hyundai Wheel Loaders: HL730-9, HL740-9, HL757-9, HL760-9, HL770-9, and others in the 7 and 9 series.

· CASE Wheel Loaders: 1221E and 1221F models.

Excavator Spare Parts VOE14598793 STAY for Volvo Construction Equipment EC120D EC140D EC160D EC170D EC180D

The Excavator Spare Parts VOE14598793 STAY is a premium structural support component tailored for Volvo D-series excavators. It provides stable mounting and reinforcement for key parts, ensures equipment structural integrity, integrates seamlessly, and performs reliably in harsh construction environments.

Key Features

· Custom-engineered for perfect compatibility with Volvo D-series target models

· High load-bearing capacity to maintain stable component mounting

· Rigid structural design for long-lasting support and vibration resistance

· Weatherproof and corrosion-resistant for durability in outdoor conditions

· Strict adherence to Volvo OEM specifications for consistent functionality

Compatible Models

· Volvo Construction Equipment: EC120D, EC140D, EC160D, EC170D, EC180D

Volvo EC480E Die-Cast Excavator Model – High-Detail Metal Alloy Replica

The Volvo EC480E die-cast excavator model is a premium, high-precision replica designed to accurately represent the structure and appearance of the Volvo EC480E heavy-duty excavator. Built with a durable metal alloy body, the model showcases detailed hydraulic cylinders, realistic bucket teeth, finely crafted handrails, track assemblies, and a highly accurate cabin interior.

The boom, arm, and bucket are fully movable, allowing the model to demonstrate realistic excavation motions. The track system is smoothly operational, providing additional authenticity for display or demonstration use. The model features Volvo’s signature color scheme and precise decals, enhancing both visual appeal and brand recognition.

This model is suitable for:

-

Construction equipment collector displays

-

Dealer showroom decoration

-

Promotional and corporate gifts

-

Engineering machinery training demonstrations

-

Volvo machine fans and model enthusiasts

SPARKLING MACHINERY offers a complete range of construction machinery models, including excavators, wheel loaders, articulated haulers, compactors, bulldozers, and more. Brands supported include CAT, Komatsu, Volvo, Kobelco, SANY, and Shantui.

The Volvo EC480E model combines realism, durability, and professional detailing, making it an excellent choice for collectors and industry professionals.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879