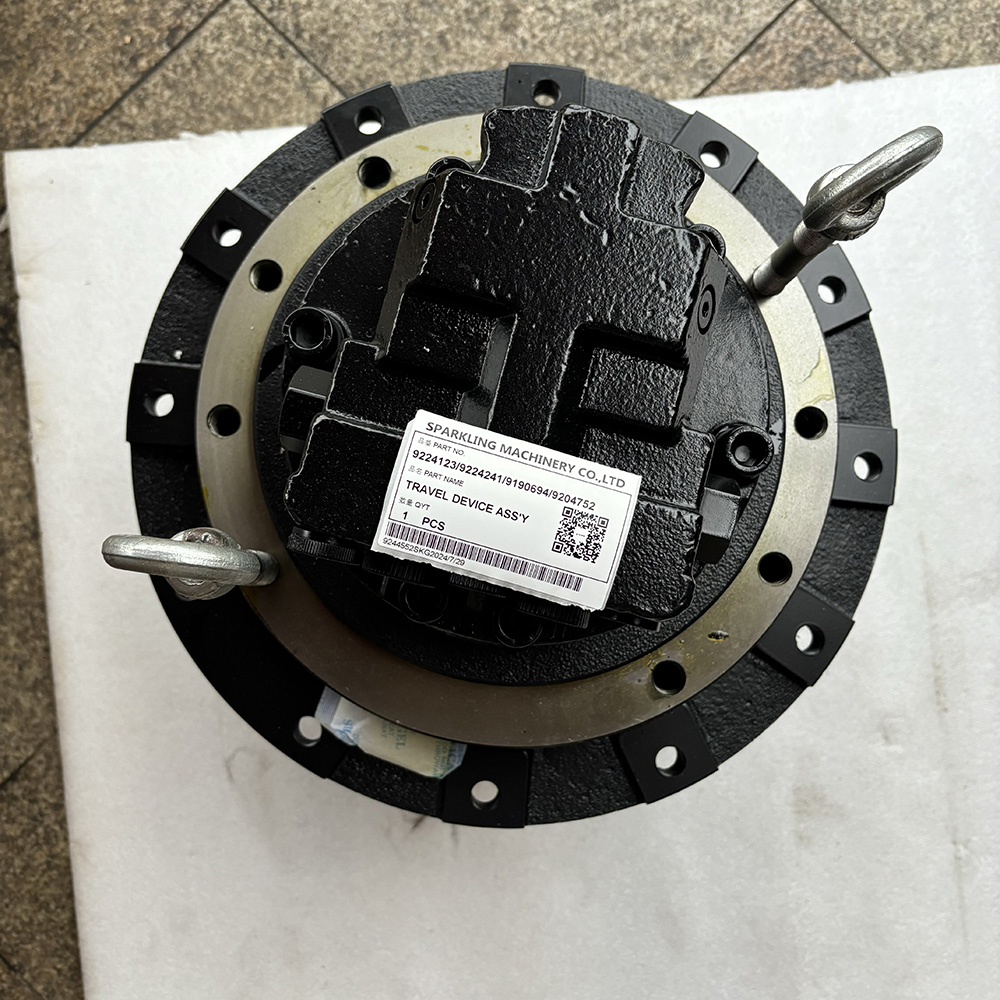

SPARKLING ZR240JC Final Drive Assy. – Reliable Excavator Part

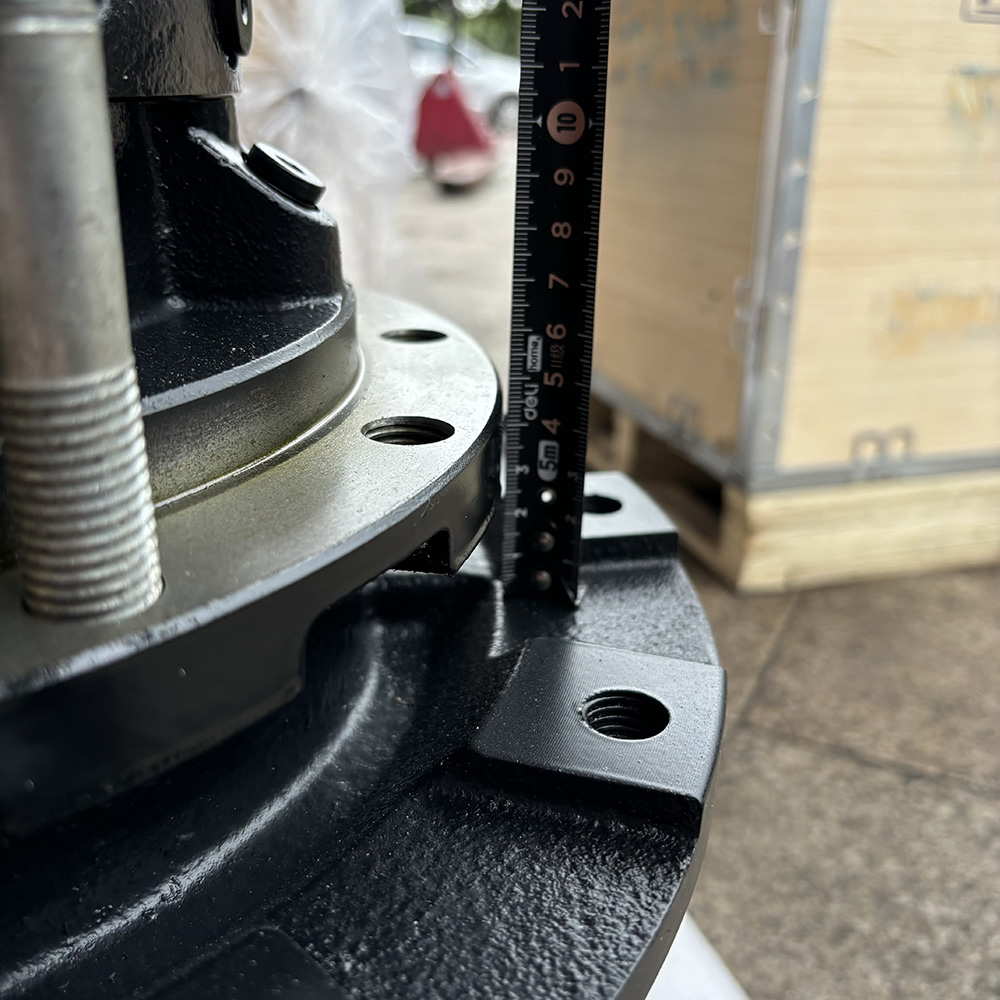

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

SPARKLING ZR240JC Final Drive Assy. – Precision and Reliability You Can Trust

The SPARKLING ZR240JC final drive assy. is engineered for performance and durability in demanding excavator operations. Since 2013, SPARKLING MACHINERY has specialized in manufacturing high-quality excavator parts, and this final drive assembly exemplifies our commitment to stability, precision, and perseverance.

Designed to seamlessly fit major excavator brands like Caterpillar, Komatsu, Hitachi, and Volvo, the ZR240JC final drive assy. undergoes rigorous quality control and precision manufacturing processes. This ensures superior reliability, allowing your machinery to operate smoothly even in harsh environments. Whether you’re involved in heavy construction or earthmoving, this final drive delivers consistent torque transmission and enhanced operational efficiency.

At SPARKLING MACHINERY, we prioritize customer satisfaction through customized solutions and expert technical support. Our global sales network and continuous after-sales service guarantee that you receive timely assistance and benefit from competitive pricing without compromising quality. With strict adherence to excellence and innovation, our products help reduce maintenance costs and extend equipment lifespan.

Choose the SPARKLING ZR240JC final drive assembly for a trusted, professional, and durable component that keeps your excavator running at peak performance. Rely on SPARKLING, your dependable partner in excavator parts, to bring stability and innovation to your heavy machinery needs.

Product Image

Q&A

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

ZR240JC ZX70 ZX70-HHE ZX80LCK ZX80SB-HCME 9224123 9224241 9190694 7204752 TRAVEL DEVICE ASS'Y FINAL DRIVE ASSY

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

Excavator Spare Parts 2.4KG 15 teeth(external) 41 teeth(internal/spline) 4110001903084 SUN GEAR for SDLG Wheel Loaders LG936 LG956

The Excavator Spare Parts 2.4KG 15 teeth(external) 41 teeth(internal/spline) 4110001903084 SUN GEAR is a core powertrain component for SDLG LG936/LG956. It ensures precise power transmission with fixed specs, delivers stable performance under heavy loads, and seamlessly integrates with SDLG’s wheel loader systems in harsh construction environments.

Key Features

· Fixed specs: 2.4KG weight, 15 external teeth & 41 internal spline teeth for perfect meshing

· Tailored for SDLG LG936 and LG956 wheel loaders

· High torque-bearing capacity for heavy-duty material handling

· Stable operation with minimal power loss

· Compliant with SDLG OEM standards for seamless integration

Compatible Models

· SDLG Wheel Loaders: LG936, LG956

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW A25G A30G A35G A40G A45G VOE17487756 CONTROL VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW A25G A30G A35G A40G A45G VOE17487756 Control Valve is a core hydraulic control component for 5 Volvo articulated hauler models (mining/construction use). It regulates hydraulic oil flow and pressure to control vehicle functions (e.g., dumping, steering), ensuring smooth and precise operation.

Meeting Volvo OEM standards (VOE17487756), it resists -30°C to 100°C temps, oil corrosion, and vibration, guaranteeing seamless compatibility and long-term reliable hydraulic control.

BULLDOZERS SPARE PARTS 708-7W-00020 708-7W-00021 708-7W-11520 HYDRAULIC FAN MOTOR FOR D275

The 708-7W-00020 / 708-7W-00021 / 708-7W-11520 hydraulic fan motor by SPARKLING MACHINERY is a reliable cooling solution for Komatsu D275 bulldozers. It offers high torque, smooth operation, and OEM fitment—ideal for maintaining engine performance under tough conditions. Fast global delivery and expert support included.

The 708-7W series hydraulic fan motor, including part numbers 708-7W-00020, 708-7W-00021, and 708-7W-11520, is a vital cooling system component specifically designed for the Komatsu D275 bulldozer. This motor powers the engine cooling fan, ensuring stable operating temperatures under extreme working conditions.

Manufactured to OEM-level specifications, the fan motor features a high-torque output, pressure-resilient seals, and durable internal components. It ensures smooth, consistent airflow, minimizing the risk of engine overheating and reducing fuel consumption associated with engine temperature spikes.

This hydraulic fan motor is engineered for easy replacement, stable high-speed rotation, and long service intervals, making it the ideal choice for maintaining your D275’s cooling system in peak condition.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879