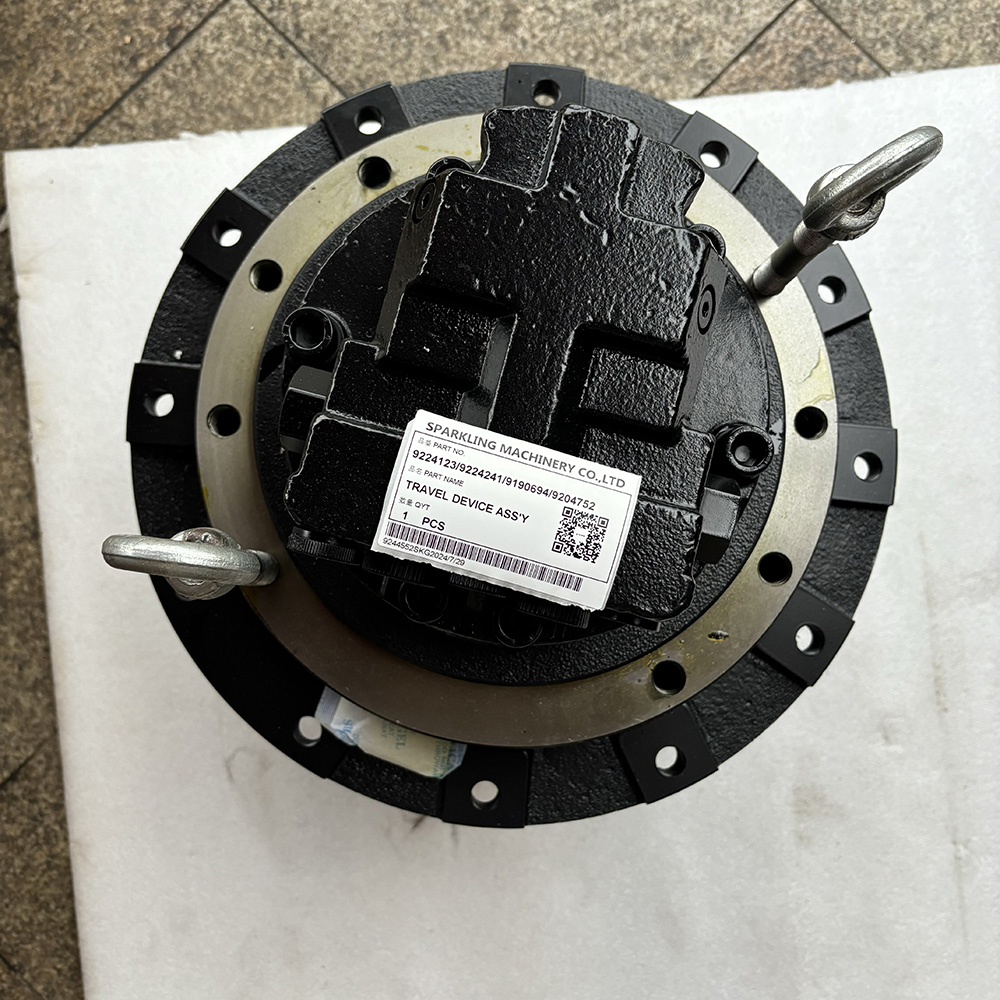

SPARKLING ZX80SB Final Drive Assembly – Durable Excavator Part

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

SPARKLING ZX80SB Final Drive Assembly – Precision and Durability You Can Trust

The SPARKLING ZX80SB final drive assembly is engineered to deliver superior performance and long-lasting reliability for your excavator. As a core component in the undercarriage system, this final drive assembly ensures smooth power transmission, enhancing your machine’s mobility and operational efficiency on any terrain.

Founded in 2013, SPARKLING MACHINERY has built a reputation for high-quality excavator parts, driven by values of stability, precision, and perseverance. Our ZX80SB final drive assembly is crafted with advanced manufacturing techniques and subjected to rigorous quality control standards to withstand demanding work environments. Compatible with major excavator brands such as Caterpillar, Komatsu, Hitachi, and Volvo, it fits perfectly and functions seamlessly, minimizing downtime and maintenance costs.

What sets SPARKLING’s ZX80SB final drive assembly apart is our commitment to customized solutions and technical expertise. We provide meticulous consultation to ensure the part meets your specific needs, backed by continuous after-sales support. Our competitive pricing does not compromise quality, enabling you to optimize operational budgets without sacrificing performance.

Whether you operate in construction, mining, or other heavy industries, trust SPARKLING ZX80SB final drive assembly to empower your excavator with enhanced durability and precision. Join countless customers worldwide who choose SPARKLING MACHINERY as their reliable partner in excavator parts.

Detailed display

FAQ

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

About other questions pls contact me directily.

ZR240JC ZX70 ZX70-HHE ZX80LCK ZX80SB-HCME 9224123 9224241 9190694 7204752 TRAVEL DEVICE ASS'Y FINAL DRIVE ASSY

The Travel Device Assembly / Final Drive Assy is an essential component in your excavator’s undercarriage system, responsible for converting hydraulic energy into mechanical movement, enabling the machine to crawl with precision, stability, and power.

This product is designed for compatibility with a range of Hitachi compact and medium excavators, ensuring direct fit, smooth torque transfer, and long-term durability even in challenging jobsite conditions.

Each unit is manufactured using high-strength gears, reliable oil seals, and precision assembly to guarantee quiet operation, resistance to wear, and stable output power.

JCB HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 25/221094 25/222891 PILOT VALVE SPARKLING MACHINERY

SPARKLING MACHINERY NEW 25/221094 25/222891 Pilot Valve is a core hydraulic control component for JCB excavators (heavy-duty construction/mining use). It regulates low-pressure hydraulic signals to control main hydraulic systems, ensuring precise, responsive operation of arms, booms, and attachments.

Meeting JCB OEM standards (25/221094, 25/222891), it resists -30°C to 100°C temps, pressure fluctuations, and corrosion, ensuring seamless compatibility and long-term reliable control performance.

VOLVO MADE IN CHINA SPARKLING MACHINERY NEW EC250D EC290B EC290C 14616531 SOLENOID VALVE

SPARKLING MACHINERY NEW EC250D EC290B EC290C 14616531 Solenoid Valve is a premium China-made hydraulic control component specifically engineered for EC250D, EC290B, and EC290C excavators. As a critical part of the hydraulic and electrical system interface, it uses electromagnetic signals to control fluid flow direction, pressure, and flow rate, enabling precise activation of hydraulic actuators such as cylinders and motors during operational tasks.

Designed to original equipment standards, it maintains rapid response times and stable switching performance even under continuous electrical and hydraulic stress. With optimized valve body design for minimal pressure loss, it adapts seamlessly to harsh working environments, from dusty construction sites to wet conditions. Backed by strict quality verification, it guarantees consistent performance to support uninterrupted machinery operation.

VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EC300D EC250D EC220D EC235D EC160D 17253748(14613051) PRESSURE SENSOR SPARKLING MACHINERY

SPARKLING MACHINERY NEW EC300D EC250D EC220D EC235D EC160D 17253748(14613051) Pressure Sensor is a critical hydraulic/pneumatic monitoring component for Volvo EC300D, EC250D, EC220D, EC235D, and EC160D excavators (widely used in construction, mining, and infrastructure projects). As the "pressure guardian", it real-time detects hydraulic system pressure (e.g., boom, bucket circuits) or pneumatic pressure—alerting operators to abnormal pressure spikes/drops during tasks like digging, lifting, and rock breaking, while preventing component damage from overpressure and ensuring stable equipment operation.

Meeting Volvo OEM standards (part nos. 17253748/14613051), it endures -30°C to 100°C temperatures, resists oil corrosion and vibration, and guarantees accurate pressure signal output. Strict testing ensures seamless compatibility with the five Volvo models and long-term pressure monitoring reliability.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879