Procurement Guide: 3Mpa Low Pressure Sensor for SK200-6 Series

- Procurement Guide: 3Mpa Low Pressure Sensor for SK200-6 Series

- Overview: What is a low pressure sensor and why it matters for excavators

- Product introduction: SPARKLING SK200-6/6E/8 3Mpa Low Pressure Sensor

- Technical specification summary for procurement

- Compatibility and model fitment: Which machines use these part numbers

- Procurement checklist: What to verify before ordering a low pressure sensor

- Comparison table: Part numbers and quick reference

- Installation and bench testing: Steps to ensure correct operation

- Calibration, diagnostics and expected readings

- Maintenance schedule and lifecycle management

- Troubleshooting common issues with low pressure sensors

- Buying tips: Avoiding counterfeit and ensuring value

- Brand advantages and supplier assessment

- FAQ — Common questions about 3Mpa low pressure sensors

- Contact & CTA: Order, request tech support or view product

- Authoritative references

- Final notes

Procurement Guide: 3Mpa Low Pressure Sensor for SK200-6 Series

Overview: What is a low pressure sensor and why it matters for excavators

The low pressure sensor (3Mpa) used on Kobelco SK200-6/6E/8 and related models is a critical safety and control component. Part numbers LC52S00019P1, YN52S00102P1, YW52S00002P1, and LS52S00013F1 are electronic hydraulic low-pressure sensors designed to monitor hydraulic pressure and trigger alerts or protective actions when system pressure falls below predefined safe thresholds. In heavy machinery like excavators, reliable low pressure sensing prevents damage to hydraulic pumps, protects actuators, and ensures operator safety by initiating alarms or automatic shutdowns when needed.

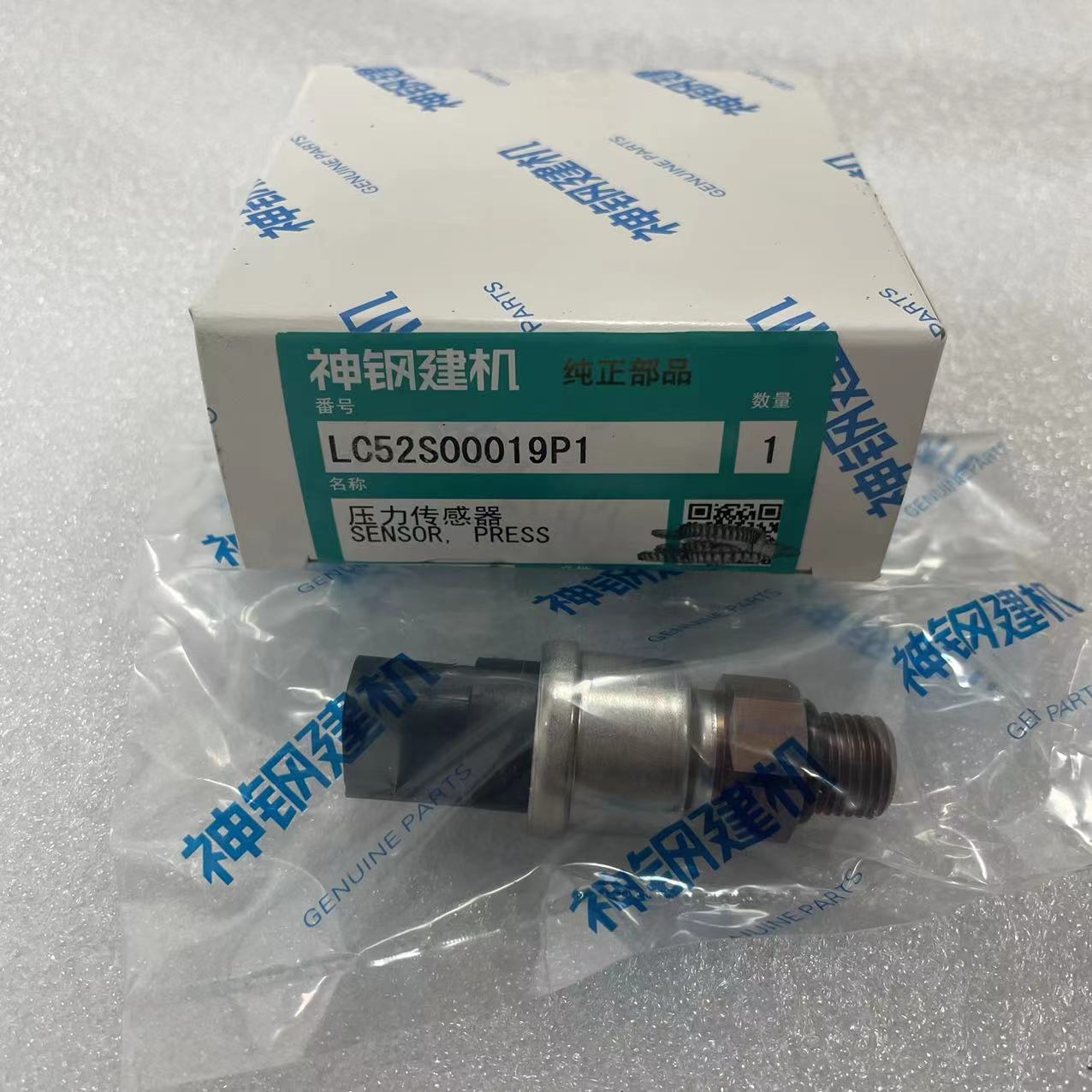

Product introduction: SPARKLING SK200-6/6E/8 3Mpa Low Pressure Sensor

The SPARKLING SK200-6/6E/8, SK250-6E/8, SK460-8, SK480-8 Low Pressure Sensor (3Mpa) models LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1 ensure precise switch control. Designed for reliable low pressure sensing, these sensors optimize performance and durability in industrial applications. The LC52S00019P1 specifically refers to an electronic hydraulic low-pressure sensor widely used in excavators to monitor hydraulic circuits and protect the system from insufficient pressure events.

Technical specification summary for procurement

When procuring a 3Mpa low pressure sensor, confirm the following technical attributes to ensure compatibility and performance: rated pressure (3.0 MPa threshold or switch point), sensor type (electronic switch vs analog output), thread size and sealing type, electrical connector and pinout, temperature tolerance, vibration and shock rating, and EMC/insulation ratings. Ask the supplier for a datasheet that shows switch actuation point, hysteresis, and environmental specifications to avoid misfit and premature failure.

Compatibility and model fitment: Which machines use these part numbers

These sensors are compatible with a broad range of Kobelco excavators and certain New Holland models. Confirm fitment before purchase by matching part numbers, thread size and connector type. Known compatible models include Kobelco SK Series: SK130-8, SK140LC-8, SK200-6/6E/8, SK210-6E/8/9, SK230-6E, SK250-6E/8, SK260-8/9, SK330-6E/8, SK350-8/9, SK460-8, SK480-8. New Holland compatible models include E70, E135, E175, E215, and E235. Always cross-reference chassis serial numbers and hydraulic schematic diagrams when in doubt.

Procurement checklist: What to verify before ordering a low pressure sensor

Follow this checklist to avoid ordering the wrong sensor or counterfeit parts:

- Confirm exact part number (LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1).

- Request OEM or verified aftermarket certificate and datasheet.

- Verify mechanical fit: thread size, sealing type, and torque specification.

- Verify electrical compatibility: connector type, voltage, and wiring color coding.

- Check operating range: 3 MPa switching threshold, environmental ratings (temperature, IP rating).

- Ask for test reports or batch calibration data if available.

- Confirm warranty, return policy, and lead time.

- Source from authorized dealers or reputable aftermarket suppliers to reduce counterfeit risk.

Comparison table: Part numbers and quick reference

Use the table below to compare part numbers and compatibility at a glance. Confirm final selection with the machine serial number and the hydraulic schematic.

| Part Number | Type | Rated Switch Pressure | Common Fit Models | Notes |

|---|---|---|---|---|

| LC52S00019P1 | Electronic hydraulic low-pressure switch | 3.0 MPa (switch threshold) | Kobelco SK200-6/6E/8, SK250-6E/8, SK330-6E/8 | Widely used; OEM reference |

| YN52S00102P1 | Electronic hydraulic low-pressure switch | 3.0 MPa | Kobelco SK460-8, SK480-8 | Variant for later models |

| YW52S00002P1 | Electronic hydraulic low-pressure switch | 3.0 MPa | SK250/350 series | Aftermarket/OEM equivalent |

| LS52S00013F1 | Electronic hydraulic low-pressure switch | 3.0 MPa | Multiple Kobelco & New Holland models | General replacement part |

Installation and bench testing: Steps to ensure correct operation

Proper installation and pre-fit testing reduce downtime and warranty claims. Follow these recommended steps:

1) Visual inspection: verify connectors, thread integrity and seals are intact on the new sensor.

2) Electrical continuity check: with the machine off, check wiring harness for opens/shorts; inspect connector pins for corrosion.

3) Bench test (if available): mount the sensor in a test rig or a hydraulic bench, slowly apply oil pressure up to and above 3.0 MPa while monitoring the sensor output (switch change, continuity or voltage output). Document actuation point and hysteresis.

4) Install on machine: apply correct thread sealant if required by OEM; torque to specified value in the service manual to avoid leaks or thread damage.

5) Commission: start the machine, cycle hydraulics and observe sensor responses under normal load. Check ECU or instrument cluster for correct alarms and messages.

Calibration, diagnostics and expected readings

Most low-pressure sensors used on these excavator models are switch-type devices that change state near the 3.0 MPa threshold. Diagnostics should include:

- Confirm closed/open state below/above threshold (use multimeter continuity).

- ECU fault codes: read machine error codes to confirm the sensor is communicating correctly.

- Hysteresis measurement: the difference between actuation and release pressures should be within the datasheet range; excessive hysteresis indicates wear or contamination.

- Electrical checks: measured resistance (for resistive switches) or expected voltage levels (for active sensors) versus datasheet values. If the datasheet is not available, request it from the supplier before final acceptance.

Maintenance schedule and lifecycle management

To extend sensor life and ensure system reliability, use a preventative maintenance schedule tailored to operating conditions. A typical guideline:

- Daily: visual check for leaks, wiring damage, or connector looseness.

- Monthly: confirm secure fastening and clean connector terminals if necessary.

- Quarterly (or every 250 operating hours): electrical function test and pressure verification.

- Annually: replace sensor if exposed to severe contamination, vibration or if it shows drift in switch point. In harsh environments, consider a proactive replacement interval of 2–4 years depending on hours and operating conditions.

Troubleshooting common issues with low pressure sensors

Common symptoms, root causes and fixes:

- Symptom: False low-pressure alarms. Possible causes: sensor contamination, wiring short, incorrect switch hysteresis. Fix: bench test sensor, clean or replace, inspect wiring.

- Symptom: No alarm when low pressure occurs. Possible causes: open circuit, failed sensor, ECU communication fault. Fix: check continuity, scan for ECU errors, replace sensor if necessary.

- Symptom: Intermittent alarm. Possible causes: loose connector, vibration-induced failure, intermittent contact. Fix: secure connectors, replace mounting grommet, or replace sensor.

Buying tips: Avoiding counterfeit and ensuring value

When purchasing a 3Mpa low pressure sensor, consider these buying tips to ensure value and reliability:

- Buy from authorized dealers or reputable industrial parts suppliers with clear return policies.

- Request batch test results or calibration certificates for critical fleet purchases.

- Avoid extremely low-cost offers without provenance — counterfeit parts can fail early and damage hydraulic systems.

- Where possible, stock a small number of certified spares to reduce downtime on critical machines.

Brand advantages and supplier assessment

Choosing the right brand or supplier matters. For example, SPARKLING-branded SK200-6 series 3Mpa low pressure sensors are designed to meet OEM switch characteristics and fitment. Evaluate brands on these criteria: proven fitment history with Kobelco or New Holland models, published datasheets, warranty terms, responsiveness of technical support, and field service availability. A supplier that offers return material authorization (RMA) and batch traceability provides better risk management for fleet operations.

FAQ — Common questions about 3Mpa low pressure sensors

Q1: How do I know if my sensor is the correct 3Mpa model?

A1: Match the OEM part number (LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1), confirm thread and connector type, and verify the switch actuation point (3.0 MPa) on the supplier datasheet.

Q2: Can I replace the sensor with a universal low-pressure switch?

A2: Only replace with a universal switch if it matches mechanical, electrical and switching characteristics. Differences in hysteresis, thread seal, or electrical output can cause malfunctions or safety risks.

Q3: What tests should I run after installation?

A3: Perform a bench actuation test (if possible), electrical continuity check, and machine commissioning under controlled hydraulic loads to confirm proper alarm and ECU response.

Q4: How often should I replace the sensor?

A4: Replacement frequency depends on operating environment. Inspect regularly; consider replacing every 2–4 years under heavy usage or sooner if performance drifts or failure signs appear.

Q5: What causes sensor failure?

A5: Most failures stem from contamination in hydraulic fluid, vibration stress, connector corrosion, electrical transient damage, or mechanical overtightening during installation.

Contact & CTA: Order, request tech support or view product

If you need to order genuine 3Mpa low pressure sensors for Kobelco SK200-6/6E/8 and related models, request datasheets, or book technical installation support, contact our sales and support team. Click to view product details or request a quotation: . For urgent fleet support, provide your machine serial number and current sensor part number to speed sourcing and compatibility checks.

Authoritative references

For technical background and standards, consult these authoritative resources:

- Pressure sensor overview — Wikipedia: https://en.wikipedia.org/wiki/Pressure_sensor

- Hydraulic system basics — Wikipedia: https://en.wikipedia.org/wiki/Hydraulics

- Kobelco Construction Machinery (official): https://www.kobelco-usa.com/

- New Holland Construction (official): https://construction.newholland.com/

- General guidance on hydraulic safety — OSHA: https://www.osha.gov/ (search hydraulic fluid power for relevant guidance)

Final notes

Procuring the correct 3Mpa low pressure sensor requires careful verification of part number, mechanical and electrical fit, and environmental specifications. Use this guide as a procurement and installation checklist to reduce risk, improve uptime, and ensure safe hydraulic system operation. When in doubt, request OEM datasheets, bench test reports, and work with authorized distributors to secure genuine parts and reliable warranty coverage.

Lifecycle Cost Considerations: LS52S00013F1 Low Pressure Sensor

The B2B Buyer’s Guide to Excavator Hydraulic Motors | SPARKLING Ultimate Insights

Choosing the Right Hydraulic Pump for Your Excavator Model

Best Practices for Installing an Excavator Hub

faq

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

SK200-6/6E/8 SK250-6E/8 SK460-8 SK480-8 LC52S00019P1 YN52S00102P1 YW52S00002P1 LS52S00013F1 3Mpa Low Pressure Sensor

The SPARKLING SK200-6/6E/8, SK250-6E/8, SK460-8, SK480-8 Low Pressure Sensor (3Mpa) models LC52S00019P1, YN52S00102P1, YW52S00002P1, LS52S00013F1 ensure precise switch control. Designed for reliable low pressure sensing, these sensors optimize performance and durability in industrial applications.

Part number LC52S00019P1 refers to an electronic hydraulic low-pressure sensor used primarily in heavy machinery such as excavators. It is designed to monitor hydraulic pressure conditions to ensure system safety, triggering alerts or shutdowns if pressure falls below safe thresholds.

Applications

The sensor is compatible with a wide range of Kobelco and some New Holland excavators, including:

Kobelco SK Series: SK130-8, SK140LC-8, SK200-6/6E/8, SK210-6E/8/9, SK230-6E, SK250-6E/8, SK260-8/9, SK330-6E/8, SK350-8/9, SK460-8, and SK480-8.

New Holland Models: E70, E135, E175, E215, and E235.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879