Choosing the Right Hydraulic Pump for Your Excavator Model

- Choosing the Right Hydraulic Pump for Your Excavator Model

- Why the hydraulic pump is the heart of hydraulic system components

- Key selection criteria: what to check before buying

- Understand pump types: gear, vane, piston — which one fits your excavator?

- How to match pump specifications to your excavator model

- Environmental, temperature, and duty considerations

- Installation, break-in, and verification best practices

- Maintenance checklist to extend pump life

- Common failure modes and how to troubleshoot

- Why Lingong HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B0610-54010 HYDRAULIC PUMP SPARKLING MACHINERY is a strong choice

- Product overview and compatibility advantages

- Product introduction

- Technical and brand strengths

- How to confirm the pump fits your model

- Comparing options: when to replace versus rebuild

- Cost vs. value: balancing upfront expense and lifecycle cost

- FAQs — Choosing and using hydraulic pumps on excavators

- Q: How do I confirm my excavator needs a B0610-54010 pump?

- Q: Can I use a different brand pump if the dimensions match?

- Q: What hydraulic fluid should I use with the B0610-54010?

- Q: How long will a high-quality pump last?

- Q: Is the B0610-54010 suitable for mining applications?

- Contact sales / View product

- Authoritative resources and further reading

Choosing the Right Hydraulic Pump for Your Excavator Model

Why the hydraulic pump is the heart of hydraulic system components

The hydraulic pump is one of the most important hydraulic system components on an excavator. It converts mechanical power from the engine into hydraulic energy — delivering pressurized fluid to actuators (cylinders and motors) that move the boom, arm, bucket, swing mechanism, and travel motors. Selecting the right pump affects performance, fuel efficiency, cycle times, controllability, and long-term reliability. Choosing an incorrect pump may lead to poor machine response, premature component wear, higher operating costs, and unexpected downtime.

Key selection criteria: what to check before buying

When evaluating replacement or upgrade pumps for an excavator, you should check these core hydraulic system components and parameters:

- OEM part number compatibility (model-specific fit and mounting)

- Maximum operating pressure (bar/MPa)

- Rated flow at operating speed (L/min or GPM)

- Displacement per revolution (cc/rev)

- Drive shaft interface and mounting pattern

- Fluid type and recommended viscosity range

- Temperature operating range and seals compatibility

- Duty cycle (continuous heavy duty vs intermittent work)

These parameters ensure the pump will integrate with other hydraulic system components and maintain the intended machine performance.

Understand pump types: gear, vane, piston — which one fits your excavator?

Excavator pumps typically fall into three categories: gear pumps, vane pumps, and piston pumps. Each has strengths and trade-offs:

- Gear pumps — simple, lower cost, robust. Best for low- to medium-pressure auxiliary circuits. Not ideal for high-efficiency main pumps on large excavators.

- Vane pumps — smoother flow and higher efficiency than gear pumps, used in medium-duty machines or pilot systems.

- Piston pumps — highest efficiency and pressure capability, common as main pumps in medium and large excavators (axial piston swashplate type frequently used).

| Pump Type | Typical Max Pressure | Efficiency | Best Use |

|---|---|---|---|

| Gear | Up to ~140–210 bar (2,000–3,000 psi) | Lower | Small excavators, auxiliary circuits |

| Vane | Up to ~140–210 bar (2,000–3,000 psi) | Medium | Medium-duty machines, pilot or steering circuits |

| Piston (axial) | Up to ~350–500 bar (5,000–7,500 psi) depending on design | High | Main pumps on medium & large excavators, heavy-duty mining |

Note: The numeric ranges above are typical industry ranges. For exact specification always check the OEM pump datasheet. (Sources cited at the end.)

How to match pump specifications to your excavator model

Follow this step-by-step approach to select the correct replacement or upgrade pump:

- Confirm the OEM part number and model — check the excavator’s parts manual or nameplate for the hydraulic pump part number. Matching the OEM part number (for example Lingong OEM B0610-54010) ensures correct mounting, shaft, and control compatibility.

- Compare flow and displacement — the pump’s rated flow at the machine’s engine speed must match the hydraulic demands of the hydraulic system components (boom, arm, swing, travel). Too high flow can cause over-speeding of actuators; too low causes sluggish operation.

- Check max operating pressure and relief settings — make sure the pump’s pressure rating meets or exceeds the machine’s maximum relief valve settings.

- Verify shaft and mounting — confirm shaft diameter, keyway or spline type, and mounting flange pattern match the excavator pump bracket.

- Confirm control type compatibility — if the pump has an integrated control (pressure compensator, load-sensing electronics), ensure it matches the machine’s control architecture.

Environmental, temperature, and duty considerations

Excavators operate in diverse environments — from cold climates to hot mines. Pumps must tolerate the jobsite conditions:

- Temperature range: select seals and fluids rated for the expected low/high ambient temperatures. Some pumps are designed to operate from -30°C to 100°C, which covers extreme cold starts and high-temperature duty cycles.

- Contaminant resistance: heavy mining and demolition environments introduce abrasive particles; choose pumps with robust filtration and wear-resistant materials.

- Duty cycle: continuous heavy lifting and travel requires pumps rated for sustained high pressures; short-cycle or auxiliary pumps can tolerate intermittent duty.

Installation, break-in, and verification best practices

Correct installation is as important as the pump selection itself. Follow these practical steps:

- Inspect the new pump for shipping damage and confirm part numbers.

- Flush the hydraulic tank and lines if contamination is suspected. Use clean recommended hydraulic fluid.

- Fit correct filters and replace return/pressure filters after major repairs.

- Use proper torque values on mounting bolts and ensure correct shaft engagement.

- Prime and bleed the system to remove air—run the pump at low idle and gradually bring up pressure while checking for leaks.

- Monitor temperature, pressure, and flow in the first 24–50 operating hours to ensure proper break-in and detect early issues.

Maintenance checklist to extend pump life

Routine maintenance targeting hydraulic system components will dramatically extend pump life and reduce downtime:

- Change hydraulic oil and filters on schedule; use the OEM-recommended fluid viscosity and specifications.

- Maintain a clean breather cap and keep the reservoir sealed from dust.

- Monitor system pressure and temperatures to detect abnormal conditions early.

- Inspect for vibration, unusual noise, or leaks which often indicate wear or misalignment.

- Keep records of pump hours, maintenance, and any faults to identify trends.

Common failure modes and how to troubleshoot

Knowing common failure patterns helps diagnose problems quickly:

- Low flow / weak performance: check for internal wear, worn vanes, cavitation due to low fluid level, clogged suction filter, or air ingestion.

- Overheating: caused by excessive system pressure, low fluid quality, poor cooling, or blocked cooling passages.

- Noisy operation: cavitation, contaminated fluid, damaged gear teeth, or loose mounting may cause noise.

- Leakage: worn seals or poor installation torque; check O-rings and flange gaskets.

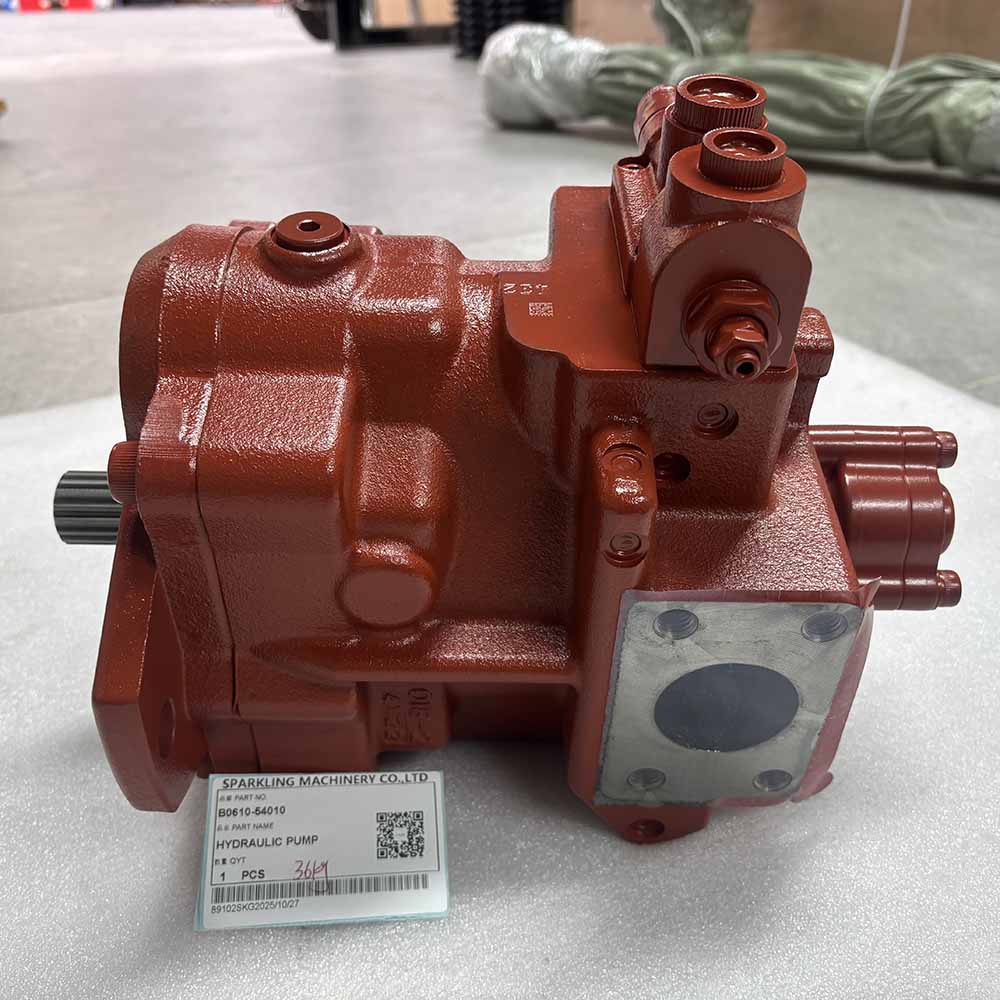

Why Lingong HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B0610-54010 HYDRAULIC PUMP SPARKLING MACHINERY is a strong choice

Product overview and compatibility advantages

When looking for a replacement pump that meets Lingong OEM standards and the demanding needs of heavy construction and mining, the Lingong NEW B0610-54010 pump from SPARKLING MACHINERY is engineered to deliver reliable hydraulic energy for critical hydraulic system components. This unit is intended to offer seamless compatibility and durable performance in challenging environments.

Product introduction

SPARKLING MACHINERY NEW B0610-54010 Hydraulic Pump is a core power component for Lingong excavators (heavy-duty construction/mining use). It delivers stable high-pressure hydraulic fluid to drive critical systems like arms, booms, and travel mechanisms.

Meeting Lingong OEM standards (B0610-54010), it resists -30°C to 100°C temps, high pressure, and wear, ensuring seamless compatibility and long-term reliable hydraulic power supply.

Technical and brand strengths

- Built to OEM B0610-54010 specifications for direct fit with Lingong models — reduces installation complexity and risk of mismatch.

- Wide operating temperature range (-30°C to 100°C) suited to cold starts and high ambient temperatures in mines and construction sites.

- Designed for high-pressure heavy-duty use (main hydraulic circuits) with attention to wear resistance and seal durability.

- Manufactured under controlled quality processes in China with material and dimensional checks to ensure interchangeability.

How to confirm the pump fits your model

Before ordering the B0610-54010 pump:

- Verify your excavator’s parts manual and confirm the OEM part number equals B0610-54010.

- Check the mounting plate, shaft spline, and flange orientation against the pump’s datasheet.

- Confirm relief valve settings and system maximum pressure compatibility.

- Ask the supplier for a dimensional drawing and serial cross-reference if unsure.

Comparing options: when to replace versus rebuild

Deciding between a new pump (like the B0610-54010) and a rebuild depends on cost, downtime, and condition:

- Replace with a new OEM-equivalent pump if internal damage is extensive, contamination has caused excessive wear, or you want the longest term warranty.

- Rebuild/repair may be cost-effective for mid-life pumps with limited wear — provided precision machining and genuine replacement parts are used.

- Consider lead time: new stock may be quicker to restore full performance than a rebuild shop backlog.

Cost vs. value: balancing upfront expense and lifecycle cost

While new OEM-equivalent pumps typically cost more upfront, they reduce risk of premature failure, improve fuel and cycle efficiency, and may lower total cost of ownership over the machine lifetime. For heavy-duty applications, reliability and uptime often justify the investment in quality replacements like the Lingong B0610-54010.

FAQs — Choosing and using hydraulic pumps on excavators

Q: How do I confirm my excavator needs a B0610-54010 pump?

A: Check the excavator parts manual for the pump part number, verify the serial plate on the pump, and confirm physical mounting and shaft compatibility. If possible, consult a dealer or parts specialist with your machine serial number.

Q: Can I use a different brand pump if the dimensions match?

A: Dimension match is necessary but not always sufficient. Confirm pressure ratings, control interfaces (load-sensing or fixed), displacement, and materials. Using a pump not designed for the system can cause performance or control issues.

Q: What hydraulic fluid should I use with the B0610-54010?

A: Use the fluid grade recommended by the excavator OEM. The B0610-54010 is designed to work with standard hydraulic oils used in Lingong machines; verify viscosity and additive specs with the machine manual.

Q: How long will a high-quality pump last?

A: Service life depends on usage, maintenance, contamination control, and operating environment. With proper fluid cleanliness and maintenance, a quality pump can last thousands of operating hours. Heavy mining duty may reduce life if filtration and oil condition are not strictly managed.

Q: Is the B0610-54010 suitable for mining applications?

A: Yes. The B0610-54010 is built to withstand heavy-duty construction and mining loads, with a wide temperature tolerance and wear-resistant design aimed at these demanding environments.

Contact sales / View product

After choosing the right hydraulic pump for your excavator model, reviewing the Lingong B0610-54010 hydraulic pump’s key specs and benefits helps confirm compatibility, durability, and long-term value.If you are ready to confirm fitment or inquire about pricing and lead times for the Lingong HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B0610-54010 HYDRAULIC PUMP SPARKLING MACHINERY, contact our parts team or request the product datasheet. Our experts can help verify OEM compatibility, recommend installation best practices, and provide warranty details.

Authoritative resources and further reading

For technical background, pump theory, and standard industry information consult these authoritative sources:

- Hydraulic pump — Wikipedia: https://en.wikipedia.org/wiki/Hydraulic_pump

- Hydraulic system — Wikipedia: https://en.wikipedia.org/wiki/Hydraulic_system

- Excavator — Wikipedia: https://en.wikipedia.org/wiki/Excavator

- Shandong Lingong Construction Machinery Co., Ltd. (SDLG) official site — for OEM references: https://www.sdlg.com

When in doubt, always consult your equipment manufacturer or an authorized parts dealer to confirm fitment and specifications.

What Buyers Should Know About HYUNDAI EXCAVATOR PARTS

Inspection Routine Before Long Excavator Jobs

Sensor Integration with Hydraulic Components in 2026

The B2B Buyer’s Guide to Final Drive for Excavators

faq

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879