Inspection Routine Before Long Excavator Jobs

- Inspection Routine Before Long Excavator Jobs

- Why a Thorough Pre-Job Inspection Matters for Excavator Parts

- Pre-Inspection Preparation: Tools, Documents, and Safety

- Step-by-Step Inspection Routine (Walkaround and Functional Checks)

- 1. Visual Walkaround

- 2. Undercarriage and Track System

- 3. Hub and Final Drive

- 4. Hydraulic System

- 5. Engine and Cooling System

- Detailed Pre-Inspection Checklist (With Frequency & Priority)

- How to Inspect and Evaluate the ZGAQ-03591 Hub and Similar Excavator Parts

- Common Failure Modes and Preventive Actions

- Lubrication and Greasing Best Practices

- Recordkeeping and Digital Inspections

- Brand Spotlight: SPARKLING MACHINERY — Hyundai-Compatible Excavator Parts

- FAQ — Inspection Routine & Excavator Parts (Including ZGAQ-03591 Hub)

- Q: How often should I inspect the hub and undercarriage on long jobs?

- Q: What signs indicate the ZGAQ-03591 Hub needs replacement?

- Q: Can I use non-OEM excavator parts to save cost?

- Q: What are the consequences of incorrect track tension?

- Q: Who should perform hub inspections?

- Contact & Product Call to Action

- References

Inspection Routine Before Long Excavator Jobs

Preparing an excavator for a long-duration job requires more than a cursory glance. Systematic pre-job inspections reduce downtime, prevent catastrophic failures, protect operator safety, and extend the life of vital excavator parts. This article walks through a clear, operator-friendly inspection routine that focuses on high-risk areas—especially undercarriage components such as the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub—and provides actionable steps, checklists, and maintenance guidance aligned with OEM quality expectations.

Why a Thorough Pre-Job Inspection Matters for Excavator Parts

Long excavator jobs (multi-day to multi-week) expose machines to sustained loads, continuous vibration, and variable environmental conditions. Critical excavator parts—tracks, track rollers, sprockets, idlers, and hubs—experience accelerated wear. A properly executed inspection routine helps:

- Identify wear before it becomes failure, reducing costly emergency repairs.

- Ensure components meet manufacturer tolerances and OEM standards (minimizing warranty and compatibility issues).

- Improve fuel efficiency and machine stability by maintaining proper undercarriage condition.

- Protect workers by ensuring safe machine operation.

When inspecting, always prioritize parts that carry the load and guide machine movement—specifically undercarriage components and hubs. For Hyundai-series machines, components like the ZGAQ-03591 Hub are designed to withstand broad temperature ranges (-30°C to 100°C) and resist impact and wear; confirming the hub and related parts are in good condition is essential for long jobs.

Pre-Inspection Preparation: Tools, Documents, and Safety

Before you start inspections, gather the right tools and documentation. This reduces rework and ensures results are accurate.

- Basic tools: flashlight, mirror, grease gun, torque wrench, feeler gauges, camera or phone for documentation.

- Documentation: operator manual, service history, parts catalog (including OEM numbers such as ZGAQ-03591), inspection checklist forms.

- PPE: gloves, safety glasses, high-visibility clothing, steel-toe boots, and lockout/tagout devices if needed.

: If you handle multiple machines, maintaining a stock of reliable replacement excavator parts—like Hyundai-compatible hubs and undercarriage assemblies—minimizes downtime. High-quality replacement parts that meet OEM specs (for example, SPARKLING MACHINERY’s ZGAQ-03591 Hub) are worth investing in for long contracts.

Step-by-Step Inspection Routine (Walkaround and Functional Checks)

This routine is designed to be practical and repeatable. Perform it daily before starting long shifts or multi-day operations.

1. Visual Walkaround

- Check for leaks: hydraulic lines, swing motor, final drives. Look underneath and around joints.

- Examine structural parts: boom, arm, bucket pins and bushes for play or cracks.

- Inspect the cab: mirrors, seat belts, gauges, and emergency equipment.

2. Undercarriage and Track System

Undercarriage condition is a primary determinant of machine uptime. Pay special attention to:

- Track tension: Correct per operator manual to reduce wear on sprockets and idlers.

- Sprockets and rollers: Look for hooked or broken teeth and flat spots on rollers.

- Track shoes: Verify bolts are tight and shoes not excessively worn.

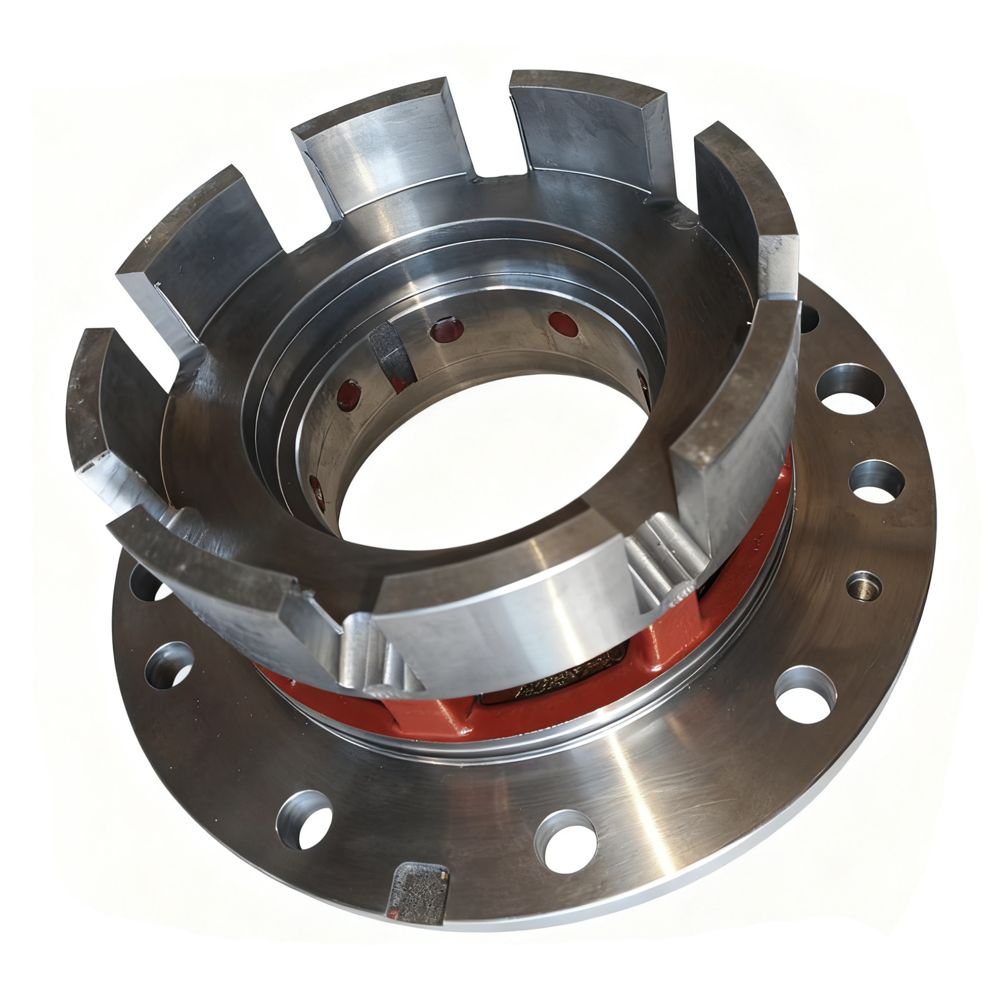

3. Hub and Final Drive

Inspect hubs (e.g., ZGAQ-03591 Hub) and final drives for leaks, heat discoloration, and abnormal play. Hubs connect track systems to axles—failure here leads to immobilization. Check grease points and ensure seals are intact.

4. Hydraulic System

- Check fluid levels and look for contamination signs (milky oil indicates water ingress).

- Inspect hoses for chafing, bulges, and secure fittings.

5. Engine and Cooling System

- Check oil, coolant, fuel filters and belts.

- Inspect radiator fins and ensure there is no debris that could cause overheating during long runs.

Detailed Pre-Inspection Checklist (With Frequency & Priority)

Use this table as a printable checklist for pre-job inspections. Frequency is based on job length and exposure—daily for long jobs, weekly for less intensive use.

| Item | What to Check | Frequency | Priority (Critical/Important/Optional) |

|---|---|---|---|

| Undercarriage (tracks, rollers, sprockets) | Wear, tension, damaged shoes, loose bolts | Daily | Critical |

| Hub & Final Drive (e.g., ZGAQ-03591 Hub) | Seals, leaks, play, temperature after run | Daily | Critical |

| Hydraulics | Hoses, fittings, fluid level, contamination | Daily | Critical |

| Engine fluids and filters | Oil level, coolant, air filter, fuel filter | Daily | Critical |

| Pins & Bushings | Wear, excessive play, lubrication | Daily/Weekly | Important |

| Electrical system | Battery mounts, terminals, lights | Weekly | Important |

| Operator controls & safety | Seat belt, horn, emergency stop, gauges | Daily | Critical |

Source references for checklist frequency and criticality are provided at the end of this article.

How to Inspect and Evaluate the ZGAQ-03591 Hub and Similar Excavator Parts

Hubs are load-bearing and subject to impact. For parts such as the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub (Hyundai OEM standard), follow these inspection steps:

- Visual inspection for cracks, weld defects, or deformation—pay attention to weld toes under the hub cap.

- Check seal integrity: any grease leakage or contamination at the hub face demands immediate attention.

- Spin test (where safe): after lifting the machine off the tracks per safety procedures, lightly rotate the wheel hub assembly to detect rough bearings or binding.

- Temperature check: after a short run, measure hub surface temperature. Excess heat vs baseline indicates internal problems. The ZGAQ-03591 Hub is rated for -30°C to 100°C operating conditions; consistent high temperatures above normal operating range are a warning sign.

- Compatibility: verify part number (e.g., ZGAQ-03591) against your machine’s parts manual to ensure fit and performance—mismatched parts accelerate wear across the undercarriage.

Using high-quality excavator parts that match OEM standards helps ensure expected tolerances, load-bearing capabilities, and environmental resilience—especially important during long jobs where component replacement is costly.

Common Failure Modes and Preventive Actions

Understanding how parts fail allows you to prevent those failures:

- Wear due to poor track tension: Keep tension within OEM range to prevent rolling elements and sprocket damage.

- Contamination in hubs and final drives: Ensure seals and breathers are intact; change oil at intervals recommended by OEM.

- Impact damage from debris or side loads: Train operators in safe travel and digging techniques; carry protective guards where available.

Lubrication and Greasing Best Practices

Proper lubrication extends life of pins, bushings, bearings, and hubs. For long jobs:

- Use manufacturer-recommended greases and oils. Check viscosity specs for expected temperature range.

- Grease points daily when machines operate continuously. Clean fittings before applying grease.

- Maintain oil change intervals—monitor oil cleanliness and water ingress.

Recordkeeping and Digital Inspections

Documenting inspections supports trend analysis and proactive maintenance. Use these practices:

- Take photos of suspect components—date and time stamped.

- Log hours on key parts (final drives, hub assemblies) and match with replacement intervals.

- Adopt digital inspection tools or apps to standardize checklists and enable remote review by maintenance supervisors.

Brand Spotlight: SPARKLING MACHINERY — Hyundai-Compatible Excavator Parts

When long jobs demand durability and interchangeability, choose replacement excavator parts that meet OEM quality and compatibility. SPARKLING MACHINERY’s NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is engineered as a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators. Key advantages include:

- OEM compatibility: Meets Hyundai OEM standard ZGAQ-03591 for fit and function.

- Temperature and impact resistance: Rated -30°C to 100°C and manufactured for wear and impact resistance—important for long-duration jobs and variable climates.

- Cost-effective supply chain: Manufactured in China with controlled quality processes to balance cost and performance for fleet operators.

- Durable load-bearing performance: Designed to support the track system securely, reducing risk of unexpected downtime.

For fleet managers focused on uptime during extended jobs, combining rigorous inspection routines with reliable replacement parts (like the ZGAQ-03591 Hub) is a proven strategy to reduce total cost of ownership.

FAQ — Inspection Routine & Excavator Parts (Including ZGAQ-03591 Hub)

Q: How often should I inspect the hub and undercarriage on long jobs?

A: Perform a full visual and functional inspection daily before work. More detailed checks (heat, play tests) should be done weekly or after heavy-impact events.

Q: What signs indicate the ZGAQ-03591 Hub needs replacement?

A: Visible cracks, persistent grease leakage, abnormal bearing noise, excessive play, or hub temperatures consistently above normal after short operation are signs to replace the hub.

Q: Can I use non-OEM excavator parts to save cost?

A: You can, but choose parts that meet OEM specifications. Poorly matched parts accelerate wear on adjacent components. SPARKLING MACHINERY parts are manufactured to Hyundai OEM ZGAQ-03591 standards for compatibility.

Q: What are the consequences of incorrect track tension?

A: Too loose leads to de-tracking and accelerated sprocket wear; too tight increases stress on rollers and final drives causing premature failure.

Q: Who should perform hub inspections?

A: Trained operators can perform daily visual checks, but any functional tests requiring lifting the machine, or diagnosis of bearing issues should be done by qualified maintenance personnel.

Contact & Product Call to Action

For reliable Hyundai-compatible excavator parts that meet OEM standards, including the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub, contact our sales team for availability, pricing, and lead times. Ensure your fleet has the right parts on hand before long jobs to minimize downtime and protect operator safety. Findings from an inspection routine before long excavator jobs should feed directly back into preventative maintenance to extend hub lifespan, ensuring small issues are addressed before they turn into costly hub failures.

Contact us to view product specifications, request a quote, or arrange expedited shipping:

References

- Health and Safety Executive (HSE) — Guidance on safe use of excavators and plant (https://www.hse.gov.uk/).

- U.S. Occupational Safety and Health Administration (OSHA) — Excavations and trenching safety resources (https://www.osha.gov/).

- Caterpillar — Operator daily inspection and maintenance recommendations (https://www.cat.com/).

- Hyundai Construction Equipment — Parts and service bulletins (manufacturer’s parts catalog and service documentation). For OEM part number reference and compatibility, consult Hyundai parts manuals.

Implementing a consistent inspection routine, prioritizing critical excavator parts like hubs and undercarriage components, and using OEM-compatible replacement parts will significantly reduce the risk of downtime during long excavator jobs.

Best professional OEM excavator parts manufacturers and supplier brands

Guide to Hydraulic Parts of Excavator for Maintenance 2026

Key Specs to Check When Purchasing HW210 Excavator Parts

The B2B Buyer’s Guide to Undercarriage Parts

faq

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879