Lingong B0610-54010 Hydraulic Pump: Key Specs and Benefits

- Lingong B0610-54010 Hydraulic Pump: Key Specs and Benefits

- Overview of the Lingong B0610-54010 Hydraulic Pump — Core hydraulic system components

- Key specifications — what to expect from this hydraulic system component

- The pump's role among hydraulic system components

- Performance benefits — why choose the Lingong B0610-54010

- Compatibility, certification and quality — aligning with hydraulic system components standards

- Installation best practices — ensuring longevity of hydraulic system components

- Maintenance, diagnostic tips and extending pump service life

- Troubleshooting common failure modes among hydraulic system components

- How to choose between OEM and aftermarket hydraulic system components — a comparison

- Sparkling Machinery & Lingong: brand advantages for hydraulic system components

- Frequently Asked Questions (FAQ) — Hydraulic pumps and hydraulic system components

- Q1: Is the B0610-54010 interchangeable with pumps from other manufacturers?

- Q2: What hydraulic fluid should I use with this pump?

- Q3: How often should I inspect or service the pump?

- Q4: Can I rebuild this pump in the field?

- Q5: What are the signs that this pump may be failing?

- Contact us / View product

- References and authoritative resources

Lingong B0610-54010 Hydraulic Pump: Key Specs and Benefits

Overview of the Lingong B0610-54010 Hydraulic Pump — Core hydraulic system components

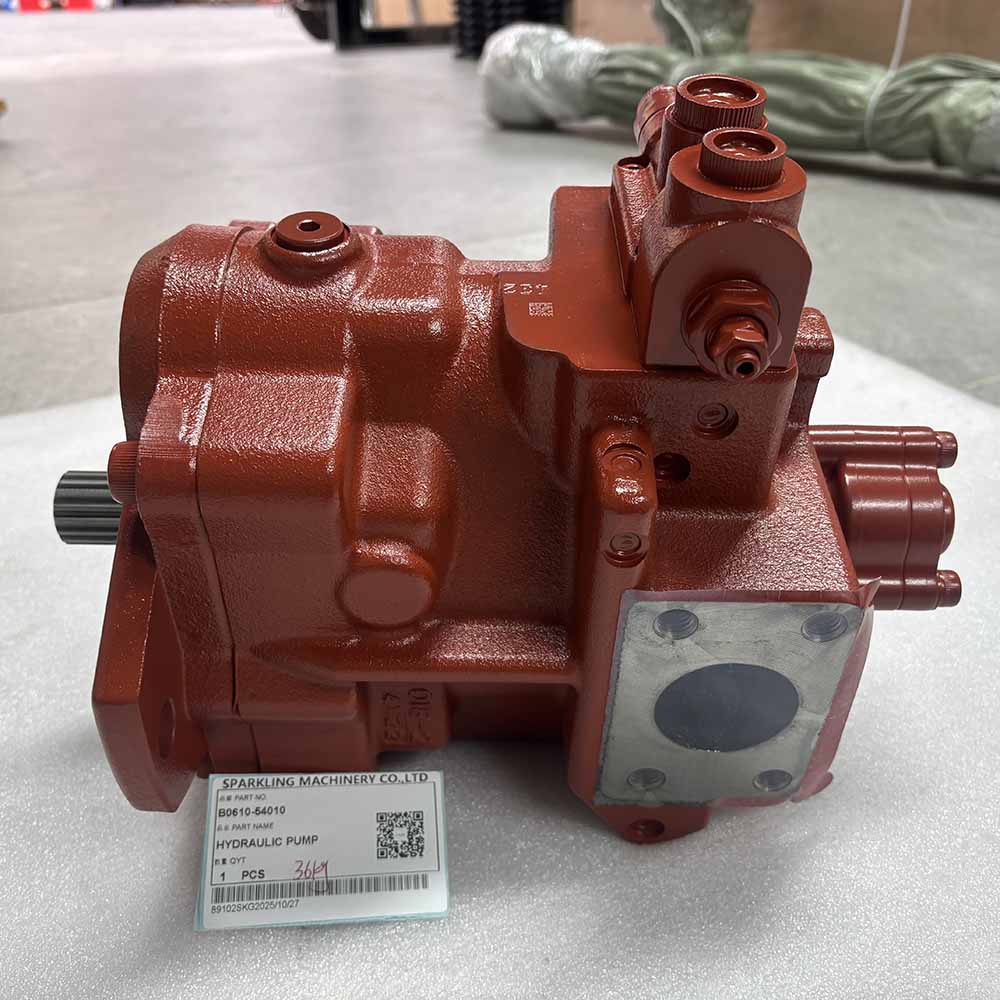

SPARKLING MACHINERY NEW B0610-54010 Hydraulic Pump is a core power component for Lingong excavators (heavy-duty construction/mining use). It delivers stable high-pressure hydraulic fluid to drive critical systems like arms, booms, and travel mechanisms.

Meeting Lingong OEM standards (B0610-54010), it resists -30°C to 100°C temps, high pressure, and wear, ensuring seamless compatibility and long-term reliable hydraulic power supply.

Key specifications — what to expect from this hydraulic system component

The B0610-54010 is engineered for reliability in demanding off-road applications. Its essential specifications address pump displacement, maximum pressure, operating temperature range, flow rate, and construction materials. These specs determine how the pump integrates into hydraulic system components and how it performs under load and in harsh environments.

| Specification | B0610-54010 (SPARKLING MACHINERY) | Typical Competitor Nominal Range |

|---|---|---|

| OEM Code | B0610-54010 | Varies (manufacturer codes) |

| Type | Axial piston pump / variable or fixed (model dependent) | Axial piston or gear pumps |

| Max Pressure | Up to 350-400 bar (model-dependent rated) | 250-420 bar |

| Flow Rate | Model-dependent; typically 50–180 L/min | 40–200 L/min |

| Operating Temp | -30°C to 100°C | -25°C to 95°C |

| Materials & Wear Protection | Hardened steel components, high-grade seals | Standard hardened components |

| Compatibility | Lingong excavators (OEM standard fit) | Some aftermarket fitment |

The pump's role among hydraulic system components

Hydraulic pumps are the heart of hydraulic system components in excavators. The B0610-54010 supplies pressurized hydraulic fluid that powers actuators (cylinders), motors (swing and travel), and directional control valves. A well-matched pump ensures smooth, predictable motion, efficient fuel usage, and reduced stress on downstream components. Choosing a pump that meets OEM tolerances reduces cavitation, pressure spikes, and premature wear across the entire hydraulic system.

Performance benefits — why choose the Lingong B0610-54010

This pump brings several measurable advantages for owners and maintenance teams focused on uptime and total cost of ownership.

- Stable high-pressure delivery: Designed to maintain pressure under load, improving bucket breakout force and hydraulic responsiveness.

- Broad temperature resilience: Rated from -30°C to 100°C, it performs reliably across cold starts and hot operating cycles common in construction and mining.

- OEM fit and interchangeability: Built to Lingong's B0610-54010 standard to ensure plug-and-play replacement without adaptive modifications.

- Wear resistance and long service life: Hardened internal components and high-quality seals reduce the frequency of rebuilds.

- Improved fuel efficiency: Optimal hydraulic power transfer reduces engine load, translating to lower fuel consumption in typical excavator cycles.

Compatibility, certification and quality — aligning with hydraulic system components standards

When integrating any pump into hydraulic system components, compatibility and certification matter. The B0610-54010 aligns with Lingong OEM standards and typical quality systems (manufacturing to ISO 9001 frameworks). It is designed to match mounting flanges, shaft interfaces, and control ports used by Lingong excavators. Choosing an OEM-standard pump eliminates the risk of mis-matched ports, incorrect displacement, or suboptimal pressure ratings.

Installation best practices — ensuring longevity of hydraulic system components

Correct installation is essential to realize the B0610-54010's benefits:

- Clean environment: Install pumps in a clean area. Contaminants are a leading cause of premature pump failure.

- Fluid compatibility and cleanliness: Use recommended hydraulic fluid grade and maintain ISO cleanliness levels (e.g., ISO 4406: recommended 18/16/13 or better depending on system).

- Proper alignment and torque: Ensure shaft alignment and correct flange torque to prevent undue bearing loads.

- Bleeding and testing: After installation, flush and bleed the circuit, then test at incremental loads to check for leaks, abnormal noise, or cavitation.

Maintenance, diagnostic tips and extending pump service life

Regular maintenance extends pump life and protects related hydraulic system components:

- Fluid analysis: Periodic hydraulic oil sampling detects wear metals, contamination levels, and oxidation before failure.

- Filter replacement: Replace suction and return filters per manufacturer intervals. A clogged suction filter can starve the pump and cause cavitation.

- Monitor temperatures and pressures: Track operating temp and pressure spikes — sustained high temperatures reduce oil life and increase wear.

- Vibration and noise monitoring: Changes in noise signature or increased vibration often precede mechanical failure and should prompt inspection.

Troubleshooting common failure modes among hydraulic system components

Understanding common failure modes helps crews react quickly:

- Cavitation: Symptoms: whining noise, reduced performance. Causes: low suction pressure, clogged suction filter, high fluid viscosity in cold starts.

- Overheating: Symptoms: high oil temp alarms, reduced efficiency. Causes: contaminated oil, failed heat exchanger, excessive load cycles.

- Leakage and seal failure: Symptoms: external fluid leaks, loss of pressure. Causes: degraded seals, incompatible fluids, excessive pressure spikes.

- Wear and scoring: Symptoms: increasing metal particles in oil, reduced flow. Causes: contamination, poor maintenance intervals.

How to choose between OEM and aftermarket hydraulic system components — a comparison

Selecting an OEM-standard pump like the B0610-54010 versus lower-cost aftermarket alternatives depends on priorities: cost, downtime risk, and lifecycle costs. The table below summarizes typical tradeoffs.

| Factor | Lingong B0610-54010 (OEM-standard) | Generic Aftermarket Pump |

|---|---|---|

| Initial Cost | Moderate to high | Lower |

| Fit & Compatibility | Guaranteed to OEM tolerances | May require adaptation |

| Reliability | High (OEM materials and QC) | Variable |

| Availability of support | Manufacturer support and documented parts | Limited |

| Impact on total cost of ownership | Lower risk of secondary damage; better long-term value | Potential higher lifecycle costs |

Sparkling Machinery & Lingong: brand advantages for hydraulic system components

Choosing SPARKLING MACHINERY's NEW B0610-54010 pump provides several brand-level advantages when considered across fleets and repair shops:

- OEM-aligned production: Manufactured to match Lingong OEM specifications, ensuring seamless interchangeability and reducing installation time.

- Quality control and materials: Production processes emphasize hardened wear surfaces, matched tolerances, and high-quality seals to withstand mining and heavy civil construction environments.

- Service network: Authorized dealers and parts distribution channels that understand Lingong excavators help maintain uptime.

- Documentation and traceability: Clear part numbers (B0610-54010), batch records, and traceable QC reduce risk during procurement and service planning.

Frequently Asked Questions (FAQ) — Hydraulic pumps and hydraulic system components

Q1: Is the B0610-54010 interchangeable with pumps from other manufacturers?

A: The B0610-54010 is manufactured to Lingong OEM dimensions and performance. While some aftermarket pumps may fit physically, using non-OEM or non-approved variants can cause performance issues or damage. Always match displacement, shaft type, mounting flange, and maximum pressure.

Q2: What hydraulic fluid should I use with this pump?

A: Use the hydraulic oil grade recommended by Lingong for your excavator model (typically anti-wear hydraulic oils meeting ASTM or ISO specs). Maintain recommended viscosity ranges for ambient temperatures and adhere to cleanliness levels (ISO 4406).

Q3: How often should I inspect or service the pump?

A: Inspect filters and fluid condition every 250 operating hours or as recommended in the machine maintenance manual. Full service intervals (filter change, fluid analysis) are typically every 500–1000 hours depending on duty cycle.

Q4: Can I rebuild this pump in the field?

A: Basic service (seal replacement, minor adjustments) can be performed by qualified technicians. For major wear or internal damage, factory remanufacture or an authorized overhaul center is recommended to preserve tolerances.

Q5: What are the signs that this pump may be failing?

A: Watch for whining noise, heat buildup, decreased hydraulic responsiveness, increased metal particles in oil analysis, or external leaks. Early detection prevents damage to pumps and other hydraulic system components.

Contact us / View product

To fully understand the real-world value of the Lingong B0610-54010 hydraulic pump, it’s important to see how hydraulic system components affect excavator efficiency across the entire machine.If you want to purchase or confirm compatibility for your Lingong excavator, contact SPARKLING MACHINERY sales at sales@sparkling-machinery.com or call +86-xxxx-xxxxxx. View detailed product datasheets and ordering information on our product page: https://www.sparkling-machinery.com/products/B0610-54010 (example link - contact us for exact datasheet).

References and authoritative resources

Below are trusted sources used for general hydraulic pump and excavator system information. For machine-specific parameters, consult your Lingong excavator maintenance manual.

- Hydraulic pump overview — Wikipedia: https://en.wikipedia.org/wiki/Hydraulic_pump

- Excavator (general) — Wikipedia: https://en.wikipedia.org/wiki/Excavator

- Shandong Lingong (SDLG) official site — Manufacturer background: https://www.sdlg.com/

- ISO 4406 cleanliness code — Overview: https://en.wikipedia.org/wiki/ISO_4406

- Basics of hydraulic systems — Hydraulics & Pneumatics resource pages: https://www.hydraulicspneumatics.com/

Note: For precise pump configuration (fixed vs variable displacement, exact flow ratings, mounting and port details) request a datasheet from SPARKLING MACHINERY or provide your machine VIN/serial number so we can verify the exact B0610-54010 variant for your excavator.

What are the application scenarios of Excavator Cooling System Parts?

The B2B Buyer’s Guide to Excavator Final Drive

Evaluating Material Quality in Excavator Hubs

Troubleshooting Hydraulic Leaks in Excavators: A Step-by-Step Approach

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879