Evaluating Material Quality in Excavator Hubs

- Evaluating Material Quality in Excavator Hubs

- Why material quality matters for excavator parts

- Product spotlight: Hyundai-compatible hub for demanding use

- Key material properties to evaluate for excavator hubs (excavator parts)

- Tensile strength and yield strength

- Hardness (wear resistance)

- Impact toughness and low-temperature performance

- Fatigue strength and microstructure

- Inspection and testing regimen for hub quality

- Incoming material verification

- Dimensional and machining checks

- Mechanical testing

- Nondestructive testing (NDT)

- Target material property ranges and acceptance criteria (quick reference)

- How manufacturing and heat treatment affect hub performance

- Surface engineering and coatings for wear protection

- Comparing hub suppliers: what to demand (commercial guidance for excavator parts buyers)

- Case study: Why Hyundai-compatible specification (ZGAQ-03591) matters

- Brand advantages: SPARKLING MACHINERY for Hyundai excavator parts

- Operational tips to maximize hub life (maintenance and installation)

- FAQ — Evaluating material quality in excavator hubs

- Q: What are the most common causes of hub failure?

- Q: How can I verify a replacement hub meets OEM specs?

- Q: Is a harder hub always better?

- Q: Which inspections are essential on arrival?

- Q: How does SPARKLING MACHINERY ensure quality for Hyundai hubs?

- Contact and product viewing (CTA)

- References and standards

Evaluating Material Quality in Excavator Hubs

Why material quality matters for excavator parts

Excavator hubs are central to the undercarriage system: they connect the track to the axle, transmit drive and braking loads, and carry high dynamic stresses during digging, loading and travel. A hub's material quality determines fatigue life, wear resistance, resistance to impact and thermal stability. Choosing and verifying the right material and treatment is therefore a commercial decision — it reduces downtime, lowers lifecycle cost, and protects operator safety for construction and mining equipment. Once you've evaluated the material quality in excavator hubs, it's essential to keep your investment protected by focusing on long-term care tips for Hyundai excavator components. Regular care not only enhances performance but also helps extend the lifespan of your excavator’s critical components.

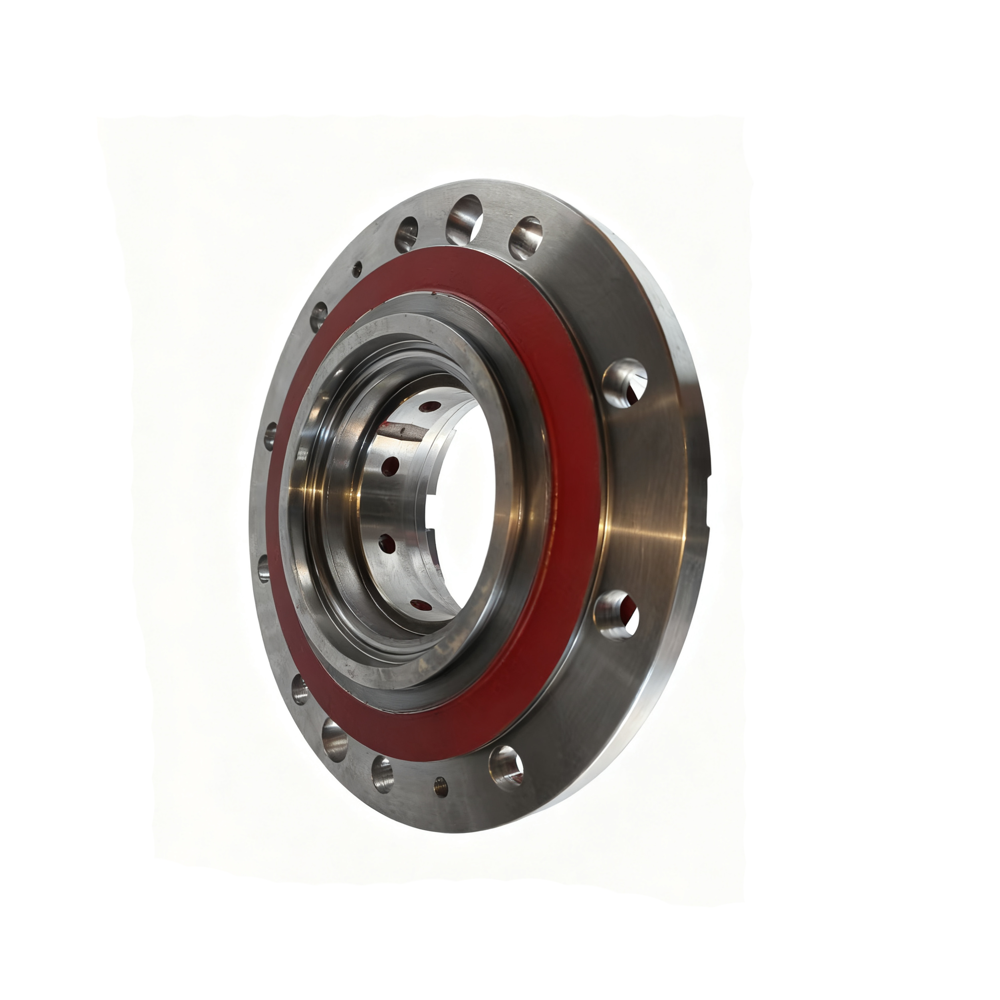

Product spotlight: Hyundai-compatible hub for demanding use

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Key material properties to evaluate for excavator hubs (excavator parts)

When assessing hubs, focus on a small set of mechanical and metallurgical properties that directly affect service life. These include tensile strength, yield strength, hardness, impact toughness, fatigue resistance, microstructure, and surface condition/coating. For each property, use industry-standard test methods to verify conformity.

Tensile strength and yield strength

Tensile tests (per ASTM A370 / ISO 6892) quantify tensile strength and yield. For quenched-and-tempered alloy steels typically used in hubs, target tensile strengths commonly fall into the 800–1100 MPa range, depending on the grade and heat treatment. These values ensure the hub can carry peak loads without macroscopic failure.

Hardness (wear resistance)

Hardness correlates with wear resistance and is typically measured on the HRC or HB scale (ISO 6506 / ISO 6508). Properly heat-treated hub areas should show consistent hardness: too soft accelerates wear; too hard increases brittleness and reduces impact resistance. A common target range for quenched-and-tempered hub sections is 28–45 HRC, depending on design and heat-treatment strategy.

Impact toughness and low-temperature performance

Excavators operate in cold climates and under sudden shocks (rock strikes). Charpy V-notch tests (ISO 148-1) at relevant service temperatures (e.g., -20°C to -30°C) verify that the material maintains adequate toughness. Typical acceptance criteria for heavily loaded parts may require Charpy energy values ≥20 J at low temperature; final acceptance should follow OEM or project specifications.

Fatigue strength and microstructure

Fatigue is the most common failure mode for hubs under cyclic loads. Metallographic examination (optical microscopy, possibly SEM) verifies proper grain size, absence of inclusions or banding, and correct tempering. Non-metallic inclusions and improper microstructure greatly reduce fatigue life. Manufacturers should provide fatigue test data or proof of process controls that minimize these defects.

Inspection and testing regimen for hub quality

A practical inspection program blends destructive and nondestructive testing to validate both material and manufacturing quality. Below is a recommended regimen for procurement and quality control of excavator hubs (excavator parts).

Incoming material verification

- Chemical analysis: Optical emission spectroscopy (OES) or X-ray fluorescence (XRF) to confirm alloy composition against specified grade.

- Certificate of Conformance: Mill test report validating heat treatment and composition.

Dimensional and machining checks

- Coordinate-measuring machine (CMM) checks for critical tolerances (bore sizes, concentricity, bolt hole positions).

- Surface finish measurement where seals or bearings interface.

Mechanical testing

- Tensile and yield tests per ASTM/ISO standards.

- Hardness mapping across critical sections to ensure consistent heat treatment.

- Charpy impact testing at or below design minimum operating temperature.

Nondestructive testing (NDT)

- Magnetic particle inspection (MPI) for surface and near-surface cracks.

- Ultrasonic testing (UT) for internal defects (inclusions, voids, laminations).

- Penetrant inspection (PT) for finer surface defects where MPI is less effective.

Target material property ranges and acceptance criteria (quick reference)

The below table shows typical target property ranges used in the industry for excavator hubs. Use OEM specifications (e.g., Hyundai ZGAQ-03591 where applicable) to finalize exact acceptance limits for a particular model.

| Property | Typical Target Range | Test / Standard |

|---|---|---|

| Tensile Strength (Rm) | 800–1,100 MPa (quenched & tempered) | ASTM A370 / ISO 6892 |

| Yield Strength (Rp0.2) | ~500–900 MPa (depends on grade) | ASTM A370 / ISO 6892 |

| Hardness (HRC) | 28–45 HRC (section-dependent) | ISO 6508 |

| Charpy V-notch (low temp) | >=20 J at -20°C to -30°C (project dependent) | ISO 148-1 |

| Elongation | >=10–15% | ASTM A370 / ISO 6892 |

Source standards: ASTM A370, ISO 6892, ISO 6508, ISO 148-1 (see Reference list).

How manufacturing and heat treatment affect hub performance

Proper quenching and tempering produce a tempered martensitic structure that balances hardness with toughness. Inadequate quenching can leave coarse pearlite or bainite, reducing strength and fatigue life. Over-tempering lowers strength and hardness. Controlled heating/cooling rates, precise tempering temperature and time, and uniformity across the part are critical. Manufacturers should document thermal cycles and provide supporting metallurgical reports.

Surface engineering and coatings for wear protection

Surface treatments — induction hardening for bearing surfaces, shot peening to introduce compressive residual stress, and protective coatings (phosphate, paint, or specialized anti-abrasion layers) — extend life. Induction hardening of contact rims or splines can provide a hard surface for wear while retaining a tougher core, improving fatigue resistance.

Comparing hub suppliers: what to demand (commercial guidance for excavator parts buyers)

When evaluating suppliers, request the following and verify them during supplier qualification:

- Material certificates and mill reports for each batch.

- Heat-treatment records (temperatures, times, quench medium).

- NDT reports (UT, MPI, PT) and inspection records.

- Dimensional inspection reports and CMM data for serial parts.

- Sample metallography and hardness maps for production lots.

- Service temperature and environmental suitability statements (e.g., -30°C to 100°C for SPARKLING MACHINERY ZGAQ-03591).

- Traceability for critical parts back to raw material batch.

Case study: Why Hyundai-compatible specification (ZGAQ-03591) matters

OEM specifications like Hyundai's ZGAQ-03591 define geometry, key tolerances, material grades and performance requirements. A hub built to this spec — such as the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub — ensures interchangeability with factory components and that the part was designed for the intended loads and operating environment. Buying hubs that match OEM specs reduces fitment risk and supports predictable maintenance schedules.

Brand advantages: SPARKLING MACHINERY for Hyundai excavator parts

When choosing replacement hubs and undercarriage components, brand and supplier capability matter. SPARKLING MACHINERY's R160W9A/R170W7/R170W7A/R170W9 ZGAQ-03591 hub offers several advantages:

- OEM compatibility: Manufactured to meet Hyundai ZGAQ-03591, ensuring fit and functional interchangeability.

- Material control: Supplied with material certificates and heat-treatment documentation for batch traceability.

- Wide operating temperature range: Rated for -30°C to 100°C, covering harsh climates and thermal loads common in construction/mining.

- Designed for abuse: Engineered to resist impact and wear typical in heavy-duty use, reducing unscheduled downtime.

- Quality assurance: Routine NDT, hardness mapping and dimensional inspection to reduce field failures.

Operational tips to maximize hub life (maintenance and installation)

Even the highest quality hub requires correct installation and maintenance to reach design life:

- Follow torque and assembly procedures spec'd by Hyundai to avoid stress concentrations.

- Keep seals and lubricants in serviceable condition; contamination accelerates wear.

- Regularly inspect for early signs of wear, bearing misalignment, or heat discoloration after heavy work cycles.

- Address track tension; over-tensioning increases bearing loads and undermines hub life.

FAQ — Evaluating material quality in excavator hubs

Q: What are the most common causes of hub failure?

A: Typical causes include fatigue from cyclic loading, poor material quality (inclusions or improper heat treatment), surface wear due to abrasive environments, improper assembly (misalignment or over-torquing), and insufficient lubrication or seal failure.

Q: How can I verify a replacement hub meets OEM specs?

A: Ask for the ZGAQ-03591 compliance statement (or the specific OEM spec number), mill test reports, hardness maps, NDT reports, and dimensional inspection records. Where possible, request sample testing or third-party inspection prior to purchase.

Q: Is a harder hub always better?

A: Not necessarily. Excessive hardness increases brittleness and can reduce impact resistance and fatigue life. The correct balance (through quench & temper) is a harder surface for wear resistance with a tough core for shock absorption.

Q: Which inspections are essential on arrival?

A: Verify documentation (material certificates), perform a visual inspection, check critical dimensions, and spot-check hardness. For high-risk lots, request UT/MPI on arrival for internal and surface flaws.

Q: How does SPARKLING MACHINERY ensure quality for Hyundai hubs?

A: SPARKLING MACHINERY manufactures the ZGAQ-03591 hub to meet Hyundai OEM standards, provides material and heat-treatment documentation, conducts NDT and hardness mapping, and designs parts to operate from -30°C to 100°C in heavy-duty environments.

Contact and product viewing (CTA)

For pricing, availability or technical data sheets for the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub and other excavator parts, contact our sales team or request a product inspection report. Our specialists can provide batch certificates, inspection records, and installation guidance to help you choose the right hub for your Hyundai excavator model.

References and standards

- ASTM A370 - Standard Test Methods and Definitions for Mechanical Testing of Steel Products. (ASTM International)

- ISO 6892 - Metallic materials — Tensile testing. (International Organization for Standardization)

- ISO 6508 / ISO 6506 - Hardness test standards for metals (Rockwell / Brinell). (ISO)

- ISO 148-1 - Metallic materials — Charpy pendulum impact test. (ISO)

- Hyundai Construction Equipment parts specifications — OEM part numbers and service manuals (manufacturer documentation where available).

- General metallurgy and heat treatment references: ISO 683 - Heat-treatable steels, alloy steels and free-cutting steels.

Note: Exact acceptance criteria and test values should refer to the OEM specification (Hyundai ZGAQ-03591) or project requirements. The ranges and recommendations above reflect typical industry practice for heavy-duty excavator undercarriage hubs.

Buying Guide: Genuine vs OEM Parts of Excavator 2026

Hydraulic Fluid and Filters: Best Practices 2026

2026 Supplier Sourcing for Hydraulic System Components

2026 Maintenance Checklist for Hydraulic System Components

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879