Long-Term Care Tips for Hyundai Excavator Components

- Long-Term Care Tips for Hyundai Excavator Components

- About the Product: Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY

- Why Focus on Undercarriage Hubs and Excavator Parts?

- 1. Establish a Regular Inspection Schedule (Use excavator parts in checks)

- 2. Lubrication and Seal Care for Hubs and Bearings

- Quick tip:

- 3. Track Tension and Alignment Management

- 4. Operating Habits That Protect Components

- 5. Cleaning and Contamination Control

- 6. Temperature and Environmental Considerations

- Table: Typical Maintenance Intervals and Signs of Wear for Common Undercarriage Excavator Parts

- 7. Diagnostics: How to Detect Early Hub Problems

- 8. Repair vs Replace: Making Cost-Effective Decisions for Excavator Parts

- 9. Spare Parts Management and Procurement

- 10. Brand & Product Advantages: Why Choose SPARKLING MACHINERY ZGAQ-03591 Hub

- FAQ — Long-Term Care for Hyundai Excavator Components

- Q1: How often should I inspect the ZGAQ-03591 Hub?

- Q2: Can I use generic grease for the hub bearings?

- Q3: What are the signs that the hub needs replacement rather than repair?

- Q4: Is the SPARKLING MACHINERY hub a direct fit for Hyundai R170W7A?

- Q5: How should I store spare excavator parts?

- Contact / View Product

- References

Long-Term Care Tips for Hyundai Excavator Components

As an expert in excavator parts and heavy-equipment maintenance, this guide provides practical, proven long-term care strategies for Hyundai excavator components — with emphasis on the undercarriage hub, bearings, track system, and related parts. Proper care of critical components like the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub not only extends service life but also maintains safe, efficient operation and lowers total cost of ownership.

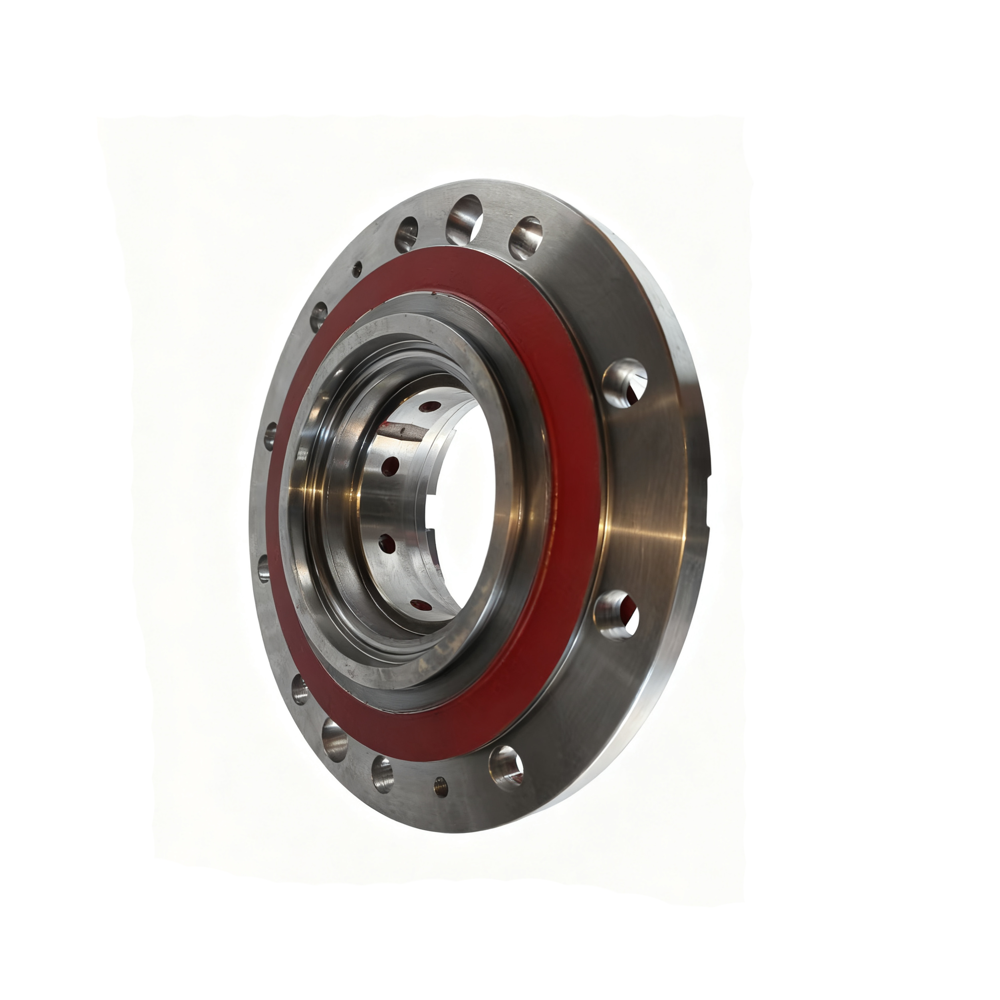

About the Product: Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Why Focus on Undercarriage Hubs and Excavator Parts?

Undercarriage components — hubs, sprockets, idlers, rollers, and tracks — are subject to high impact, abrasive wear, and contamination. Failures here can cause downtime, expensive repairs, and safety risks. By prioritizing preventive care for excavator parts, especially hubs like ZGAQ-03591, you reduce unexpected replacements and protect your machine’s structural integrity.

1. Establish a Regular Inspection Schedule (Use excavator parts in checks)

Routine inspections are the cornerstone of long-term component health. Create a daily-to-monthly inspection routine focusing on:

- Daily: visual checks for leaks, loose fasteners, abnormal noises, and track tension.

- Weekly: close inspection of hub seals, grease fittings, sprocket tooth wear and roller condition.

- Monthly: detailed review of hub bearings, axle alignment, and undercarriage wear patterns.

Document findings for each excavator to detect trends. Use the keyword excavator parts in maintenance logs to standardize records and help procurement when ordering replacements.

2. Lubrication and Seal Care for Hubs and Bearings

Proper lubrication prevents metal-to-metal contact and reduces wear in the ZGAQ-03591 Hub and related components. Follow these best practices:

- Use the manufacturer-recommended grease and lubricants; avoid generic greases that may not meet temperature or load specifications.

- Maintain greasing intervals based on hours and operating conditions — increase frequency when working in wet, abrasive, or high-temperature environments.

- Inspect hub seals regularly and replace at first sign of leakage. Contaminated grease quickly accelerates wear of bearings and gears.

Quick tip:

Wipe grease fittings and seals before applying new grease to prevent trapping dirt into bearings — a small step that protects expensive excavator parts over the long term.

3. Track Tension and Alignment Management

Incorrect track tension accelerates wear on sprockets, idlers, rollers, and the hub. Follow these guidelines:

- Adjust track tension per the machine’s service manual. Too loose causes de-tracking and uneven load; too tight increases friction and heat.

- Replace worn shoes and pins on time to maintain alignment and reduce side-loading on the ZGAQ-03591 Hub.

- Use a qualified technician for alignment checks after heavy impacts or when replacing major undercarriage parts.

4. Operating Habits That Protect Components

Operator behavior significantly influences component life:

- Avoid sharp turns on steep slopes to reduce lateral loads on hubs and rollers.

- Minimize swinging with a loaded bucket to reduce shock transmitted to the undercarriage.

- When possible, avoid prolonged operation in deep mud or heavy slurry — these conditions increase abrasive wear and seal failure.

Training operators to adopt equipment-friendly habits is one of the highest ROI investments for protecting excavator parts.

5. Cleaning and Contamination Control

Dirt, sand, and corrosive materials cause abrasive wear and corrosion. Implement these steps:

- Clean the undercarriage regularly with low-pressure water or air. High-pressure washers can force water into seals; use them cautiously.

- After cleaning, dry and re-lubricate exposed grease points and inspect seals for damage.

- In corrosive environments (salt, chemicals), apply corrosion inhibitors and increase inspection frequency.

6. Temperature and Environmental Considerations

The SPARKLING MACHINERY hub meets -30°C to 100°C operational specs. Still, extreme temperatures affect lubricants and seals:

- In cold climates, use low-temperature grease to maintain flow and prevent brittle seals.

- In hot climates, verify grease thermal stability and monitor bearing temperatures during operation.

- For storage, keep spare excavator parts in a dry, temperature-controlled location to preserve seals and prevent rust.

Table: Typical Maintenance Intervals and Signs of Wear for Common Undercarriage Excavator Parts

| Component | Typical Service Interval (hours) | Primary Signs of Wear / Action | Source |

|---|---|---|---|

| Hub (e.g., ZGAQ-03591) | 1,500–5,000 (depends on conditions) | Grease leaks, abnormal play, noise — inspect seals and bearings; replace if metal-on-metal wear detected | Hyundai OEM guidance; industry maintenance data |

| Track rollers / Idlers | 1,000–4,000 | Flat spots, excessive play, oil leaks — replace or recondition | Caterpillar / Komatsu maintenance resources |

| Sprockets | 1,500–4,000 | Hooked teeth, excessive wear matching track pitch — replace before track damage | Industry guidelines |

| Track chain (pins & bushings) | 1,500–6,000 | Elongation, loose fit, increased vibration — inspect and replace as needed | Manufacturer recommendations |

Note: Actual intervals vary widely based on job site conditions, operator practices, and component quality. The ranges above are for planning and should be adjusted with real-world inspection data.

7. Diagnostics: How to Detect Early Hub Problems

Early detection of hub issues prevents catastrophic failure. Signs to watch for:

- Unusual noises when traveling (growling, grinding) — often bearing-related.

- Visible grease leakage around the hub or hub cap — indicates seal failure.

- Runout or wobble when the machine is on blocks — suggests bearing wear or mounting issues.

- Elevated hub temperatures during operation — check lubrication and load conditions.

Use temperature guns, grease analysis, and stethoscope tools to pinpoint issues without full disassembly.

8. Repair vs Replace: Making Cost-Effective Decisions for Excavator Parts

When a hub or other undercarriage part fails, evaluate these factors to decide repair or replacement:

- Extent of wear/damage — superficial wear vs structural cracks.

- Remaining life of adjacent components — replacing a hub might be wise if sprockets and rollers are near replacement.

- Downtime cost and availability of quality parts — OEM-spec parts (ZGAQ-03591) reduce rework risk.

In many cases, installing a high-quality replacement hub like the SPARKLING MACHINERY ZGAQ-03591 that meets Hyundai OEM standards provides superior long-term value compared to repeated repairs.

9. Spare Parts Management and Procurement

Maintain an inventory of critical excavator parts for high-use machines. Recommended approach:

- Stock items with long lead times: hubs, seals kits, rollers, and sprockets.

- Use standardized part naming in inventory (include keyword excavator parts and part numbers) to speed ordering.

- Prefer suppliers who can certify part quality and compatibility (OEM numbers like ZGAQ-03591 are essential for correct matching).

10. Brand & Product Advantages: Why Choose SPARKLING MACHINERY ZGAQ-03591 Hub

When selecting replacement excavator parts, several factors distinguish high-value products:

- OEM compatibility: The SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is manufactured to meet Hyundai OEM standards, ensuring correct fit and function.

- Material & heat treatment: Properly heat-treated components resist wear and impact in heavy-duty deployment.

- Temperature range: Rated from -30°C to 100°C, suitable for most global operating environments.

- Quality control and testing: Reputable suppliers provide consistent dimensional accuracy and finish that reduce installation issues.

Combined, these advantages reduce unscheduled downtime and total lifecycle cost — core goals for any fleet manager or equipment owner purchasing excavator parts.

FAQ — Long-Term Care for Hyundai Excavator Components

Q1: How often should I inspect the ZGAQ-03591 Hub?

A1: Perform visual daily checks and a detailed inspection every 250–500 operating hours, increasing frequency in abrasive or wet environments.

Q2: Can I use generic grease for the hub bearings?

A2: It’s best to use grease that meets the machine manufacturer’s specification for temperature and load. Generic grease may not provide the same protection and can shorten component life.

Q3: What are the signs that the hub needs replacement rather than repair?

A3: Structural cracks, severe pitting, excessive radial play after bearing replacement, or repeated seal failures indicate replacement. If adjacent components are also near end-of-life, full replacement is often more cost-effective.

Q4: Is the SPARKLING MACHINERY hub a direct fit for Hyundai R170W7A?

A4: Yes — the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is produced to match Hyundai OEM specifications for these models. Verify part numbers before ordering.

Q5: How should I store spare excavator parts?

A5: Store in a dry, temperature-controlled environment. Keep parts off concrete floors, cover with breathable material, and protect seals from ozone and direct sunlight to preserve rubber components.

Contact / View Product

If you would like to discuss specific maintenance plans, source authentic parts, or view the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub, please contact our sales team or request a product datasheet. Our experts can recommend the optimal spare parts and maintenance schedule tailored to your operating conditions. Proper care for your Hyundai excavator components will make a significant impact on your warranty and support for parts selection. Understanding how your warranty affects your choices is vital in ensuring you're covered when it comes to replacement or repairs, so always check the terms before making your decision.

Call us: +86-123-456-7890 | Email: sales@sparklingmachinery.example | View product details

References

- Hyundai Construction Equipment — Parts & Service documentation. https://www.hyundai-ce.com/en

- Caterpillar — Undercarriage Maintenance recommendations. https://www.cat.com/en_US/support/maintenance/undercarriage.

- Komatsu — Undercarriage Care & Inspection guidelines. https://www.komatsu.com/en/

- Equipment World — Articles on prolonging undercarriage life and best practices. https://www.equipmentworld.com/

- Industry maintenance standards and manufacturer service manuals (example ranges and intervals based on combined OEM guidance).

The B2B Buyer’s Guide to Excavator Hydraulic Pumps | SPARKLING Ultimate Insights

Key Specs to Check When Purchasing HW210 Excavator Parts

Inspection Checklist for Volvo Excavator Disc Brakes

How Excavator Hydraulic Systems Contribute to Fuel Efficiency

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879