Inspection Checklist for Volvo Excavator Disc Brakes

- Pre-Operation Visual and Functional Checks for Brake Disc Safety

- 1. Walkaround visual inspection

- 2. Check for fluid leaks and caliper operation

- 3. Functional brake test

- Key Measurements and Tools for Accurate Brake Disc Assessment

- 1. Measuring rotor thickness (minimum thickness & wear)

- 2. Measuring lateral runout (disc runout)

- 3. Checking pad thickness and contact area

- Wear Limits, Damage Types and Replacement Criteria

- 1. Common wear patterns and causes

- 2. Numerical wear limits and tolerance table

- 3. When to machine vs. replace

- Troubleshooting, Prevention and Long-Term Maintenance

- 1. Troubleshooting common braking issues

- 2. Preventive maintenance best practices

- 3. Environmental and operational considerations

- Brand Compatibility and Why Choose SPARKLING MACHINERY VOE14558962

- 1. OEM standard fit and material specification

- 2. Durability claims and testing environment

- 3. Product overview (manufacturer description)

- Standards, References and Further Reading

- 1. Technical references

- 2. Record keeping and traceability

- Practical Checklists (Printable Steps)

- 1. Daily pre-operation checklist

- 2. Monthly/100-hour maintenance checklist

- 3. Replacement decision matrix

- Frequently Asked Questions (FAQ)

- Q1: How often should I inspect the brake disc on my Volvo EW160/EW180 excavator?

- Q2: Can I machine (resurface) the VOE14558962 disc rotor?

- Q3: What tools are required for a proper brake disc inspection?

- Q4: Are aftermarket discs reliable compared to OEM?

- Q5: Where can I get the exact OEM limits for VOE14558962?

This inspection guide helps fleet managers, technicians, and operators perform a thorough brake disc inspection on Volvo wheeled excavators using the VOLVO OEM-standard SPARKLING MACHINERY Disc Brake (VOE14558962). It focuses on the brake disc (disc rotor) condition, friction surface, rotor thickness, runout, corrosion, thermal damage, and related brake system components to ensure reliable stopping power on road and off-road tasks.

Inspection results often guide purchasing decisions, making it useful to review the top specifications to compare for Volvo excavator brake discs.

Pre-Operation Visual and Functional Checks for Brake Disc Safety

1. Walkaround visual inspection

Start each shift with a walkaround inspection. Look for obvious signs of damage on the brake disc (rotor) such as deep grooves, scoring, thermal cracks, heavy rust, or missing hardware. Check the brake caliper and backing plate for deformation. A visually compromised disc reduces braking torque and can lead to uneven pad wear or brake judder.

2. Check for fluid leaks and caliper operation

Inspect hydraulic lines, fittings, and wheel cylinders for brake fluid leakage or seepage. Ensure the caliper moves freely on its guide pins; seized calipers can cause continuous friction and rapid disc wear. Test the parking brake mechanism on wheeled excavators to confirm engagement and release.

3. Functional brake test

Perform a low-speed brake test in a safe area before full operation. Listen for abnormal noises (squeal, grinding) which may indicate contamination (oil/grease) on the friction surface or severe pad-to-disc damage. Confirm consistent braking force and no pulling to one side.

Key Measurements and Tools for Accurate Brake Disc Assessment

1. Measuring rotor thickness (minimum thickness & wear)

Use a caliper or micrometer to measure disc thickness (rotor thickness) at several points around the disc. Record the thinnest measurement. Compare with OEM minimum thickness where available. If OEM data for VOE14558962 is not immediately available, tag and remove for further inspection when thickness approaches a conservatively set limit (e.g., 10-15% above the expected minimum for heavy equipment). Always consult the Volvo parts manual for precise limit values. For general guidance, refer to brake disc standards on Wikipedia.

2. Measuring lateral runout (disc runout)

Disc runout (axial runout) causes pulsation felt at the brake pedal or ruddering on wheel machines. Use a dial indicator mounted on a fixed point and rotate the wheel to measure maximum runout. Typical acceptable runout for heavy equipment is smaller than that for passenger cars; refer to the OEM specification. Excessive runout requires machining (if allowed) or replacement of the rotor.

3. Checking pad thickness and contact area

Inspect brake pads for thickness and even contact across the rotor. Thin or uneven pads accelerate rotor wear. Use a feeler gauge or direct measurement to monitor pad wear. Replace pads before they reach the backing plate to protect the disc friction surface.

Wear Limits, Damage Types and Replacement Criteria

1. Common wear patterns and causes

Common wear types include grooving from debris, thermal cracking from overheating, scoring caused by metallic contamination, and corrosion pitting when excavators work in wet/saline environments. Identify whether wear is gradual (normal) or accelerated (contamination, caliper issue, overheating).

2. Numerical wear limits and tolerance table

Below is a suggested reference table for inspection purposes. Always defer to the Volvo service manual for exact VOE14558962 limits. These values are illustrative and intended to assist on-site decision-making until OEM data is confirmed.

| Measurement / Condition | Acceptable Limit (Reference) | Action |

|---|---|---|

| Rotor minimum thickness | Consult Volvo OEM; tag replacement if ≤ recommended min or if ≤10–15% above min | Replace rotor |

| Max lateral runout | Typical heavy-equipment target <0.3–0.5 mm (confirm OEM) | Machine or replace depending on severity |

| Pad remaining thickness | Replace before metal backing is exposed (manufacturer specific) | Replace pads and inspect rotor |

| Heat cracks (visible) | Any through-thickness cracks are unacceptable | Replace rotor |

| Corrosion pitting | Deep pits that affect friction surface >2 mm depth or widespread | Replace rotor |

3. When to machine vs. replace

Some rotors can be machined (resurfaced) if material removal will not reduce thickness below OEM minimum and there are no heat cracks. For VOE14558962 and similar heavy-use rotors, machining is often limited by the original material spec. When in doubt — especially for equipment used in public works or heavy-load tasks — replacement with a new OEM-compatible disc offers the most reliable result.

Troubleshooting, Prevention and Long-Term Maintenance

1. Troubleshooting common braking issues

Symptom: Brake noise (squeal) — Causes: glazed disc/pad, contamination, or loose hardware. Action: Clean friction surface, replace contaminated pads, torque hardware to spec.

Symptom: Pulling to one side — Causes: Caliper seizure, uneven pad wear, hydraulic imbalance. Action: Inspect calipers, bleed system, measure discs and pads.

2. Preventive maintenance best practices

- Scheduled inspections: Establish a records-based inspection interval for brake discs and pads based on operating hours and duty-cycle.

- Clean and protect: Keep rotors and calipers free of oil/grease; apply corrosion-preventive measures during long storage.

- Torque and hardware checks: Regularly verify wheel and braking assembly fasteners to prevent vibration-related damage.

3. Environmental and operational considerations

Excavators used in road construction, municipal works, or material handling face different stressors: urban debris and salt (corrosion), heavy stopping cycles (thermal stress), and off-road impacts (impact damage). Choose brake components rated for expected temperature ranges and vibration. SPARKLING MACHINERY's VOE14558962 disc brake is tested to perform across -30°C to 90°C and endure high friction conditions, which helps mitigate these environmental risks.

Brand Compatibility and Why Choose SPARKLING MACHINERY VOE14558962

1. OEM standard fit and material specification

The SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is manufactured to meet Volvo OEM standards and is designed specifically for VOLVO EW160 and EW180 series wheeled excavators. Correct fitment ensures proper caliper alignment, pad contact, and braking torque. For more information on Volvo construction equipment and parts standards, see Volvo Construction Equipment.

2. Durability claims and testing environment

SPARKLING MACHINERY advertises tests for friction, thermal cycles, vibration, wear and corrosion resistance. These tests help ensure consistent braking performance across heavy-duty cycles. Matching or exceeding OEM test protocols reduces the risk of premature failure and bolsters E-E-A-T credibility when purchasing replacement parts.

3. Product overview (manufacturer description)

SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is a dedicated safety component for VOLVO EW160C/EW160D/EW160E/EW180C/EW180D wheeled excavators (used in road construction, municipal engineering, and material handling). As the core of the braking system, it provides stable stopping force to ensure safe on-road travel and off-road operation, preventing accidents during tasks like loading or navigating uneven terrain.

Meeting VOLVO OEM standards (part no. VOE14558962), it endures high friction, -30°C to 90°C temperatures, and vibration. It resists wear and corrosion, ensuring long-term braking reliability for the five VOLVO models, with strict testing guaranteeing compatibility and safe performance.

Standards, References and Further Reading

1. Technical references

For general information on brake discs and their function, see the technical summary at Wikipedia: Brake disc. For guidance on ensuring fitment and OEM compatibility, consult Volvo CE's parts documentation at Volvo Construction Equipment. For industry standards and technical papers on braking systems, refer to SAE International.

2. Record keeping and traceability

Maintain inspection logs including date, inspector, measurements (thickness, runout), pad condition, and any corrective action (machine/replace). Traceability ensures safety audits can confirm that components like VOE14558962 were fitted and serviced per schedule.

Practical Checklists (Printable Steps)

1. Daily pre-operation checklist

- Visual disc surface inspection (scoring, cracks, heavy rust)

- Check pad wear and backing plate exposure

- Inspect hydraulic lines and caliper for leaks

- Functional low-speed brake test

2. Monthly/100-hour maintenance checklist

- Measure rotor thickness at 3–6 points and log values

- Measure lateral runout with dial indicator

- Inspect for heat checking and warpage

- Check and lubricate caliper guide pins, torque fasteners

3. Replacement decision matrix

If any of the following are true: rotor thickness ≤ OEM minimum, visible through-thickness cracks, deep scoring affecting contact area, or runout exceeds OEM tolerance — replace the rotor. Replace pads whenever rotor replacement is performed unless new pads were recently installed and meet spec.

Frequently Asked Questions (FAQ)

Q1: How often should I inspect the brake disc on my Volvo EW160/EW180 excavator?

A: Perform daily visual checks and a functional brake test before operation. More detailed measurements (thickness, runout) should be done at scheduled maintenance intervals (e.g., every 100 operating hours) or sooner if symptoms occur. Follow Volvo's service schedule for exact intervals.

Q2: Can I machine (resurface) the VOE14558962 disc rotor?

A: Machining is only permissible if the resulting thickness remains above Volvo's specified minimum. Because heavy-equipment rotors have strict material and safety limits, replacement is often recommended to ensure long-term reliability. Check the Volvo service manual for VOE14558962 before machining.

Q3: What tools are required for a proper brake disc inspection?

A: Essential tools include a micrometer or caliper for thickness, a dial indicator for runout, a torque wrench for fasteners, a basic hydraulic pressure/bleed kit for system checks, and hand tools for caliper removal. Use PPE and follow lockout/tagout procedures during inspection.

Q4: Are aftermarket discs reliable compared to OEM?

A: Quality aftermarket discs that meet OEM specifications and testing standards can be reliable. SPARKLING MACHINERY's VOE14558962 is produced to match Volvo OEM fit and performance claims. Verify manufacturer test data, traceability, and certifications when selecting parts.

Q5: Where can I get the exact OEM limits for VOE14558962?

A: Consult Volvo's parts and service documentation or an authorized Volvo dealer. Volvo Construction Equipment's official site provides contact and service channels: Volvo CE.

If you have specific machine serial numbers or need assistance selecting the correct part, contact our sales and technical team for fitment confirmation, pricing, and availability. View the product and request a quote: SPARKLING MACHINERY VOE14558962 Disc Brake or Contact Customer Service.

Hyundai Excavator Parts: What Makes Quality Parts Stand Out

Preventive Maintenance: Replacing Bearings on Hyundai Excavators

Parts of Excavator: Cost Breakdown and Savings Tips 2026

Top Excavator Hydraulic Components to Replace in 2026

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

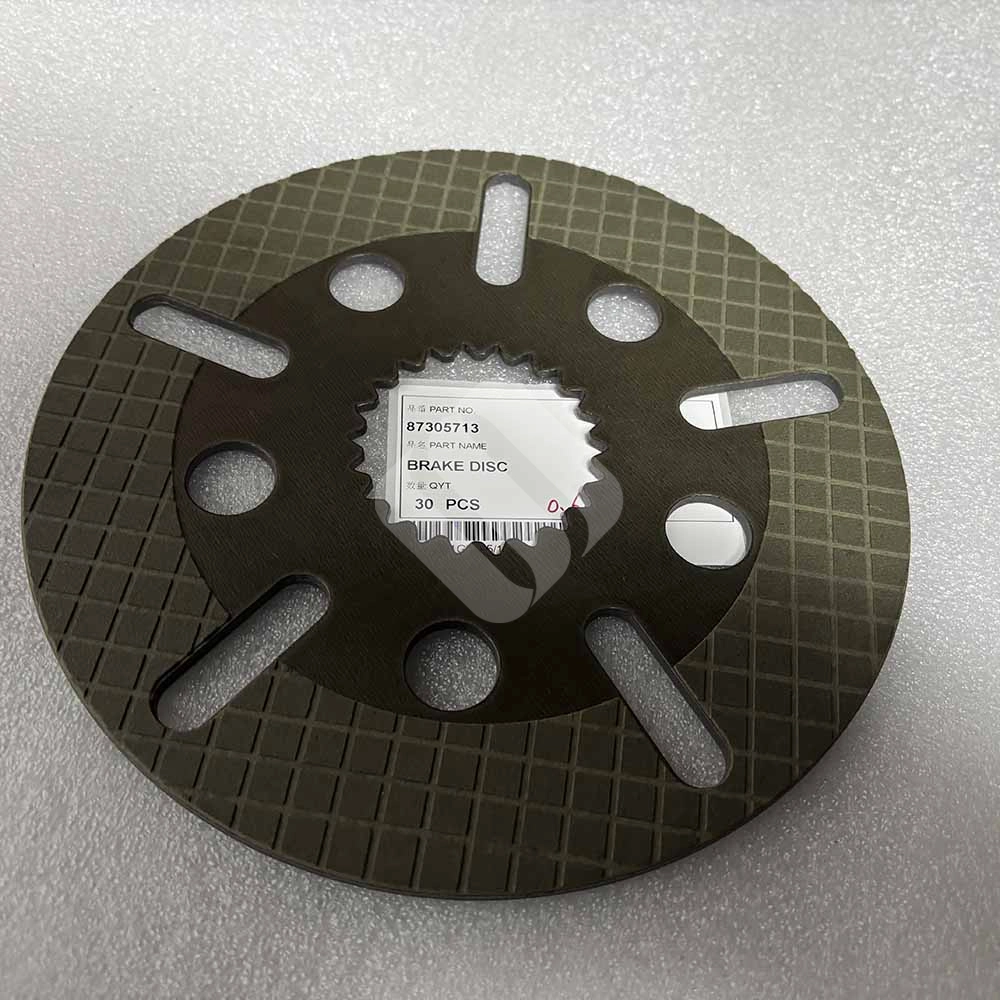

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B110B B100B LB90.B B90B B95B 87305713 BRAKE DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW B110B B100B LB90.B B90B B95B 87305713 Brake Disc is a core braking component for Volvo B110B/B100B/LB90.B/B90B/B95B excavators (heavy-duty construction/mining use). It works with brake pads to generate friction, ensuring reliable stopping and operational safety.

Meeting Volvo OEM standards (87305713), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable braking performance.

New Holland Backhoe Loaders 87305713 83959970 47123297 Brake Disc

87305713 is a specific industrial part number for a Brake Disc (or Friction Plate) used in agricultural and construction machinery, primarily manufactured by New Holland.

1.This friction disc is designed for oil-immersed (wet) braking systems. It is commonly found in:

New Holland Backhoe Loaders: Models including B90B, B100B, B110B, B115B, LB75, LB90, LB110, and LB115.

Ford Tractors: Series 550, 555, and 655.

Case IH: Certain models sharing the same drivetrain components

2. Technical Specifications

Outside Diameter (OD): ~204.75 mm

Inside Diameter (ID): ~55.88 mm (spline area)

Thickness: 4.8 mm

Teeth Count: 22 Teeth

Material: Paper-based friction material with a waffle-groove pattern for oil circulation and cooling

3. Cross-Reference Numbers

This part is often interchangeable with the following OEM and aftermarket numbers:

CNH: 83959970, 47123297

Ford/NH Original: E6NN2A097BB

Hyundai Wheel Loaders HL730-9 HL730-9A HL730-9S ZGAQ-03450 0501.323.355 DISC-INNER CLUTCH CHINA MADE

Part numbers 0501.323.355 (a ZF part number) and ZGAQ-03450 (a Hyundai part number) both refer to a Friction Disc used in the brake or clutch assembly of heavy machinery transmissions and axles.

This component is an inner clutch or brake friction plate/disc. It is a critical wear item within the drivetrain assembly (likely a ZF axle or transmission) responsible for creating the necessary friction to engage clutches or apply brakes in heavy equipment.

Compatible Equipment

This friction disc is commonly used in Hyundai wheel loaders and other construction equipment that utilize compatible ZF axles:

Hyundai Wheel Loaders: HL730-9, HL730-9A, HL730-9S, HL730TM-9A.

Other Compatible Equipment: Various backhoe loaders, including certain models by John Deere (e.g., 310, 315, 210K, 310SJ, 325K)

Part Numbers: 0501.323.355, 0501323355, ZGAQ-03450, ZGAQ03450, AT339543, 482-6743, VOE 15071853, S06/42932

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel Excavators

ZTAM-00615 is an OEM-compatible support kit for Hyundai R140W-7/R140W-7A excavators. It provides essential structural reinforcement and vibration damping for key components, ensuring reliable performance under heavy loads and harsh working conditions in construction and engineering applications.

Key Features

· OEM direct‑fit design: Exact matching of mounting positions, hole spacing, and geometric dimensions for Hyundai R140W‑7 / R140W‑7A — plug‑and‑play without modification.

· High‑strength structural support: Heavy‑duty steel construction with reinforced stress points for excellent load capacity and impact resistance.

· Stable & durable: Anti‑wear, anti‑deformation, and anti‑corrosion surface treatment for long service life in harsh environments.

Compatible Models: Hyundai Wheel Excavators R140W-7, R140W-7A

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879