Preventive Maintenance: Replacing Bearings on Hyundai Excavators

- Why Bearing Replacement Matters for Excavator Reliability

- How bearings affect excavator performance

- Typical failure modes and warning signs

- Understanding the ZGAQ-02328 Taper Roller Bearing for Hyundai Excavators

- Product overview

- Compatibility with Hyundai models

- Relevant engineering standards and references

- Step-by-step: Replacing a Taper Roller Bearing on Hyundai Excavators

- Preparation and safety

- Removal of worn bearing

- Installation and verification

- Inspecting Related Parts of an Excavator During Bearing Service

- Checks for the undercarriage and swing assembly

- Hydraulic and drivetrain considerations

- Seals, lubrication and contamination control

- Cost, Life Expectancy and Parts Comparison

- Comparing OEM vs aftermarket bearings

- Maintenance intervals and lifecycle management

- Comparative table: ZGAQ-02328 vs Generic Aftermarket

- Practical Preventive Maintenance Plan for Bearings

- Inspection checklist

- Record keeping and digital monitoring

- Training and parts inventory

- FAQ — Preventive Maintenance & Bearings for Hyundai Excavators

- Q1: How often should I replace the taper roller bearing on my Hyundai excavator?

- Q2: Can I use a generic bearing instead of ZGAQ-02328?

- Q3: What are the signs that a bearing failure has damaged other components?

- Q4: What lubricants are recommended?

- Q5: Where can I find technical resources for correct torque and service procedures?

Preventive maintenance for heavy earthmoving equipment directly impacts uptime, safety, and operating cost. For Hyundai excavators such as HW210, R200W7/R200W7A and R210W-9, bearings like the ZGAQ-02328 Taper Roller Bearing are critical rotating components that support combined radial and axial loads in swing and final drive assemblies. Replacing bearings before catastrophic failure preserves related parts of an excavator — including the swing gear, pin & bushing links, final drives, and hydraulic systems — and reduces downtime in construction and mining operations.

Why Bearing Replacement Matters for Excavator Reliability

How bearings affect excavator performance

Bearings transmit loads between rotating shafts and stationary housings. In excavators, a failed bearing can cause uneven rotation of the slewing ring or final drive, creating vibration that accelerates wear on the boom, arm, bucket linkage, pins, and bushings. Preventive replacement protects hydraulic pumps and swing motors by preventing shock loads and contamination migration through seals.

Typical failure modes and warning signs

- Unusual noise (grinding or growling) during swing or travel operations.

- Increased operating vibration and heat around the swing gear or final drive.

- Hydraulic anomalies like pressure spikes caused by binding loads transferred to the motor or gearbox.

- Visible lubricant leakage, contamination, or metal debris in oil/grease.

Early detection and replacement reduce secondary damage to major parts of an excavator such as the undercarriage, track rollers, sprockets, and swing bearing housings.

Understanding the ZGAQ-02328 Taper Roller Bearing for Hyundai Excavators

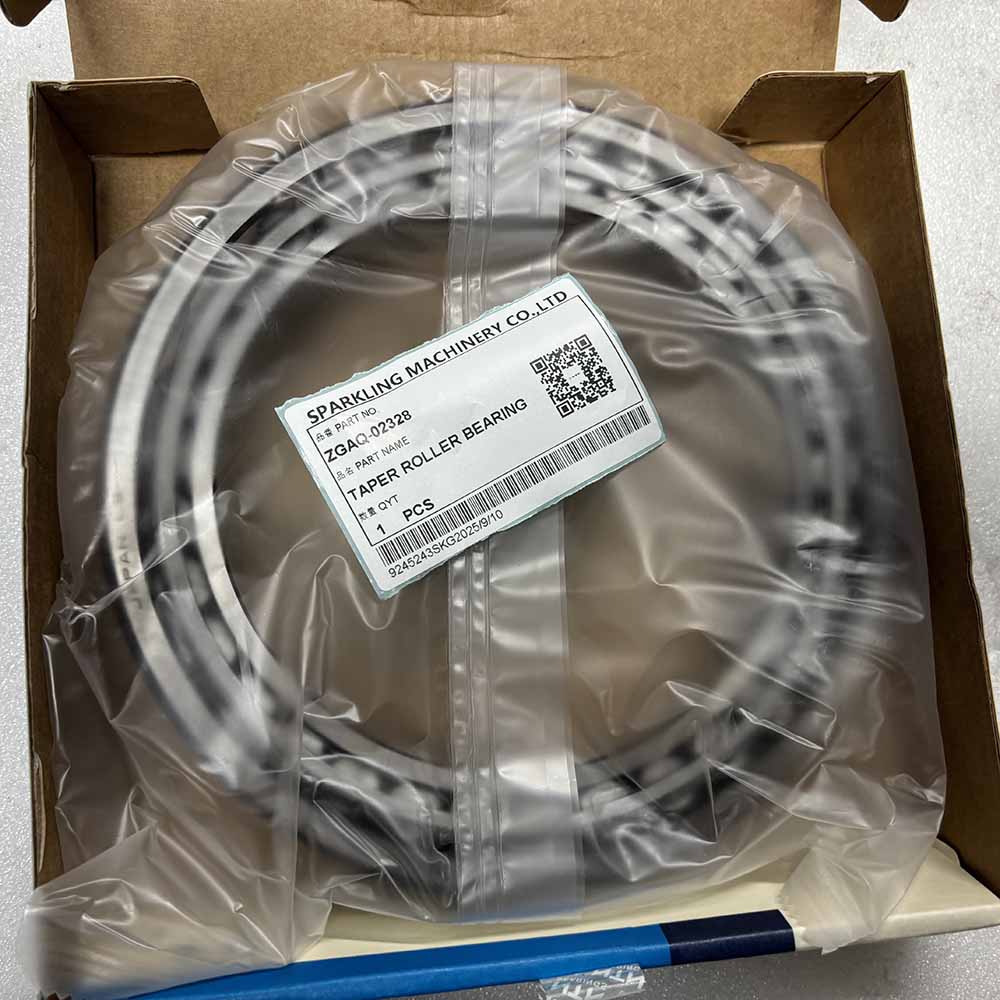

Product overview

SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is a core rotating component for Hyundai excavators (construction/mining use). It withstands combined radial and axial loads, ensuring smooth rotation of key shaft parts.

Meeting Hyundai OEM standards (Part No.: ZGAQ-02328), it delivers high wear resistance and load capacity, guaranteeing seamless compatibility and long-term stable operational performance.

Compatibility with Hyundai models

This bearing is specifically fitted to several Hyundai models, including HW210, R200W7, R200W7A and R210W-9. Correct part selection prevents interference with associated components — for example, incorrect bearing dimensions can misalign the swing gear or final drive housing, increasing wear on seals and gear teeth.

Relevant engineering standards and references

Design and life expectancy of rolling bearings are typically evaluated using international standards such as ISO 281 (bearing life calculation). For general background on excavators and rotating bearings, see authoritative resources: Excavator (Wikipedia) https://en.wikipedia.org/wiki/Excavator and Roller bearing (Wikipedia) https://en.wikipedia.org/wiki/Roller_bearing. Manufacturer and industry references like Hyundai Construction Equipment https://www.hyundai-ce.com/ are useful for model-level service data.

Step-by-step: Replacing a Taper Roller Bearing on Hyundai Excavators

Preparation and safety

Before starting, secure the machine on level ground, isolate the battery, relieve hydraulic pressure, and support the boom and arm to avoid movement. Gather proper tools: torque wrench, bearing puller/driver sets, precision feeler gauges, clean solvents, and approved lubricants. Use OEM or OEM-equivalent parts such as SPARKLING MACHINERY ZGAQ-02328 to maintain fit and performance. Always consult the machine's service manual for model-specific torque values and disassembly order.

Removal of worn bearing

1. Remove covers, seals, and fasteners to access the bearing housing (swing gear or final drive). 2. Capture and examine lubricant samples; metallic particles indicate bearing damage. 3. Use a hydraulic or mechanical puller to extract the bearing race carefully; avoid hammering on mating shafts. 4. Inspect mating components (shaft journal, housing bore, seals, snap rings, and adjacent gear surfaces) for scoring, pitting, or deformation. Replace any damaged parts to prevent premature failure of the new bearing.

Installation and verification

1. Clean all mating surfaces with solvent and dry thoroughly. 2. Pre-fit new bearing (ZGAQ-02328) and apply OEM-approved lubricant. 3. Use a bearing driver to press the bearing evenly until it seats fully; avoid applying force to rollers. 4. Reassemble seals and housings, torque fasteners to spec, and refill with correct grease or oil. 5. Run the excavator through operational checks: monitor temperature, vibrations, and hydraulic pressure. Record baseline readings for future preventive maintenance.

Inspecting Related Parts of an Excavator During Bearing Service

Checks for the undercarriage and swing assembly

When replacing a bearing, inspect the undercarriage (track shoes, rollers, idlers, sprockets) and swing assembly for alignment and wear. Misalignment or excessive play in pins and bushings can transfer abnormal loads to bearings. Correct worn track tension or replace damaged pins and bushings to restore proper load distribution across the final drive and swing bearing.

Hydraulic and drivetrain considerations

Check hydraulic hoses, swing motors, and gearboxes for contamination and pressure irregularities. Bearing failure can permit metal debris into hydraulic systems; replace filters and inspect the swing motor and gearbox internal components. Ensure final drive seals are intact to prevent lubricant loss and contamination.

Seals, lubrication and contamination control

Seals and proper lubrication are the frontline defense for bearings. Replace all seals during bearing service and use lubricants that meet OEM specifications. Implement contamination controls such as breathers and clean filling practices. Regular oil sampling and particle testing will help detect early metal wear.

Cost, Life Expectancy and Parts Comparison

Comparing OEM vs aftermarket bearings

Choosing OEM-compliant bearings like SPARKLING MACHINERY ZGAQ-02328 balances cost and reliability. Generic bearings may be cheaper initially but can have inconsistent heat treatment, material quality, and dimensional tolerances that reduce life and increase risk to other parts of an excavator.

Maintenance intervals and lifecycle management

Typical bearing lifecycle depends on operating hours, load cycles, environment (dust, moisture), and maintenance discipline. In severe environments (mining, demolition), inspect bearings at shorter intervals. Track and log vibration and temperature baselines to trigger preventive replacement before catastrophic failure.

Comparative table: ZGAQ-02328 vs Generic Aftermarket

| Specification | ZGAQ-02328 (SPARKLING MACHINERY, OEM Standard) | Generic Aftermarket |

|---|---|---|

| OEM Compatibility | Designed to Hyundai Part No. ZGAQ-02328; guaranteed fit for HW210/R200W7/R210W-9 | Variable; may require machining or shims for correct fit |

| Material & Heat Treatment | High-grade bearing steel with OEM-specified heat treatment | Quality varies; lower-grade steels reported in some suppliers |

| Load & Wear Resistance | High wear resistance & rated for combined radial/axial loads | Often adequate initially; may show earlier wear under heavy loads |

| Warranty & Traceability | Manufacturer warranty and traceable batch records | Limited or no traceability |

Source references on bearing life calculations and standards: ISO 281 (bearing life) https://www.iso.org/standard/68041., SKF bearing life methods https://www.skf.com.

Practical Preventive Maintenance Plan for Bearings

Inspection checklist

- Daily: Visual check for leaks, unusual noise, or temperature spikes around swing and final drive housings.

- Weekly: Clean breather vents, check grease levels, monitor vibration via portable analyzer.

- Monthly: Oil/grease sampling and particle analysis; check torque on critical fasteners.

- Annual or operating-hour based: Full disassembly inspection and preventive replacement if vibration/contamination thresholds exceeded.

Record keeping and digital monitoring

Maintain service logs with dates, operating hours, and baseline readings for temperature and vibration. Consider retrofitting condition-monitoring sensors on critical rotating parts to enable predictive maintenance and reduce unnecessary disassembly.

Training and parts inventory

Train technicians to recognize early signs of bearing distress and to perform correct removal/installation techniques. Stock critical parts such as ZGAQ-02328 bearings, seals, and lubricant to avoid long equipment downtime.

FAQ — Preventive Maintenance & Bearings for Hyundai Excavators

Q1: How often should I replace the taper roller bearing on my Hyundai excavator?

A1: There is no universal interval; replacement depends on operating conditions, load cycles, and inspection results. Use vibration/temperature baselines and oil/grease analysis to decide. In heavy-duty operations, inspect quarterly and consider preventive replacement based on condition rather than fixed hours.

Q2: Can I use a generic bearing instead of ZGAQ-02328?

A2: Generic bearings may fit but often lack consistent material and heat-treatment standards. Using an OEM or OEM-compliant part like SPARKLING MACHINERY ZGAQ-02328 reduces risk of premature failure and secondary damage to other parts of an excavator. For safety and reliability, OEM-equivalent parts are recommended.

Q3: What are the signs that a bearing failure has damaged other components?

A3: Look for metal particles in lubricant, scoring on shaft journals or housing bores, increased backlash or play in the swing gear, and abnormal wear on pins, bushings, or final drive gears. If these are present, replace or machine the damaged parts along with the bearing.

Q4: What lubricants are recommended?

A4: Use lubricants that meet the Hyundai service manual specifications for your model. For sealed bearings, use manufacturer-recommended grease; for final drives, use the specified gear or hydraulic oils. Replace seals when replacing bearings to maintain contaminant exclusion.

Q5: Where can I find technical resources for correct torque and service procedures?

A5: Refer to your Hyundai excavator service manual or official Hyundai Construction Equipment resources https://www.hyundai-ce.com/. For bearing standards and life calculation methodology, consult ISO 281 https://www.iso.org/standard/68041. and industrial bearing references such as SKF https://www.skf.com.

If you have further questions about parts compatibility or need OEM-quality replacement bearings, contact our technical sales team or view the product page for the SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing. We provide model-specific fitment support for Hyundai excavator models HW210, R200W7, R200W7A and R210W-9.

Contact us: For pricing, availability, and installation support — reach out to our parts team or click to view the product and request a quote.

Guide to R170W7 Excavator Parts and Key Components

Benefits of VOE14558962 Brake Disc for Volvo EW160/EW180

How Warranty and Support Affect Parts Selection

How to Maintain Your Excavator's Hydraulic System for Longevity

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879