How to Maintain Your Excavator's Hydraulic System for Longevity

- How to Maintain Your Excavator's Hydraulic System for Longevity

- Why maintaining excavator hydraulic parts matters

- Daily visual checks to catch issues early

- Choose the right hydraulic fluid and manage it properly

- Track and replace filters to control contamination

- Inspect hoses, fittings, and seals regularly

- Manage heat and keep coolers clean

- Bleeding, air control, and operational techniques

- Scheduled maintenance plan (comparison table)

- Troubleshooting common hydraulic problems

- Why quality excavator hydraulic parts and correct sourcing matter

- Best practices for storage, transport, and winter operation

- Training, documentation, and record-keeping

- When to call a specialist

- FAQ: Common questions about maintaining excavator hydraulic parts

- How often should I change hydraulic oil?

- What are the signs of hydraulic contamination?

- Can I mix hydraulic oils from different brands?

- Are aftermarket excavator hydraulic parts reliable?

- How can I reduce hydraulic system downtime?

- Final takeaway

How to Maintain Your Excavator's Hydraulic System for Longevity

Why maintaining excavator hydraulic parts matters

A well-maintained hydraulic system reduces downtime, lowers repair costs, improves fuel efficiency, and extends the life of expensive components such as pumps, valves, cylinders, and motors. Contamination, heat, improper fluids, and worn hoses accelerate wear, so proactive care pays back quickly in uptime and total cost of ownership.

Daily visual checks to catch issues early

Performing short daily inspections is one of the most effective ways to protect excavator hydraulic parts. Check for visible fluid leaks, damaged hoses, loose fittings, unusual noises, and abnormal heat. Confirm hydraulic fluid level and look for cloudiness or milky appearance (which can indicate water contamination). A 5–10 minute walkaround at the start of each shift prevents small problems from becoming major failures.

Choose the right hydraulic fluid and manage it properly

Using the correct hydraulic oil is essential. Always follow the OEM specification (viscosity, anti-wear properties, and temperature range). Modern hydraulic fluids can extend service intervals, but compatibility with seals and system materials must be verified before switching products. Change oil according to manufacturer guidance and monitor fluid condition by visual checks and, if possible, periodic lab analysis.

Track and replace filters to control contamination

Contamination is the leading cause of hydraulic failures. Use high-quality filters designed for excavator hydraulic parts and replace them at recommended intervals. Consider installing a particle counter or sampling program if your machine operates in very dirty conditions. Typical filtration strategies include suction (pre-) filters, pressure filters, and return-line filtration. Keep breathers and reservoir caps clean — they are an often-overlooked entry point for contaminants.

Inspect hoses, fittings, and seals regularly

Hoses, crimp joints, and seals are wear items. Look for abrasion, swelling, kinks, and external cuts. Replace hoses showing signs of aging rather than waiting for a burst. Use correct hose assemblies rated for system pressure and temperature. Tighten fittings to torque specs to prevent leaks but avoid overtightening, which can damage threads and seals.

Manage heat and keep coolers clean

Hydraulic systems run hotter under heavy loads or high ambient temperatures. Excessive heat degrades hydraulic oil and accelerates component wear. Ensure hydraulic coolers and radiators are clean and free of debris; check coolant flow in hybrid systems. If your work environment is high-temperature or continuous heavy-duty, consider additional cooling capacity or staged work cycles to reduce thermal stress on excavator hydraulic parts.

Bleeding, air control, and operational techniques

Air in hydraulic systems causes spongy controls and erosion of pumps. Follow correct bleeding procedures after repairs or hose changes. Train operators in good practices: avoid rapid directional changes under high load, minimize unnecessary idling, and warm up systems in cold weather to protect seals and oil viscosity. Proper operator behavior significantly reduces wear on hydraulic components.

Scheduled maintenance plan (comparison table)

Below is a practical comparison of common maintenance tasks and suggested frequencies. Adjust intervals according to OEM guidance and actual operating conditions.

| Task | Frequency (typical) | Why it matters |

|---|---|---|

| Daily walkaround and leak check | Daily | Catches leaks and visible damage before failure |

| Hydraulic fluid level and visual check | Daily to weekly | Detects contamination, low fluid, and early problems |

| Air breather and reservoir cap inspection | Weekly | Prevents ingress of moisture and particles |

| Hydraulic filters replacement | Per OEM or heavy-duty: monthly to every 500 hours | Maintains cleanliness, prolongs pump and valve life |

| Hydraulic oil analysis | Every 250–1,000 hours (site dependent) | Detects wear metals, contamination, and degradation |

| Hose and fitting inspection | Monthly or every service interval | Prevents sudden failures and unplanned downtime |

| Cooler/radiator cleaning | Monthly or as-needed depending on environment | Controls system temperature and oil life |

| Full hydraulic system inspection and service | Annually or per OEM hours | Comprehensive check of pumps, valves, cylinders, and controls |

Troubleshooting common hydraulic problems

Recognize symptoms early: slow or erratic cylinder movement suggests contamination or air; unusual noises (rattling, whining) often point to pump cavitation or low fluid; overheating indicates cooling issues. Use a systematic approach: check fluid level and condition first, then filters, then look for external leaks and finally evaluate internal wear with pressure testing. Keep a log of symptoms and repairs for trend analysis.

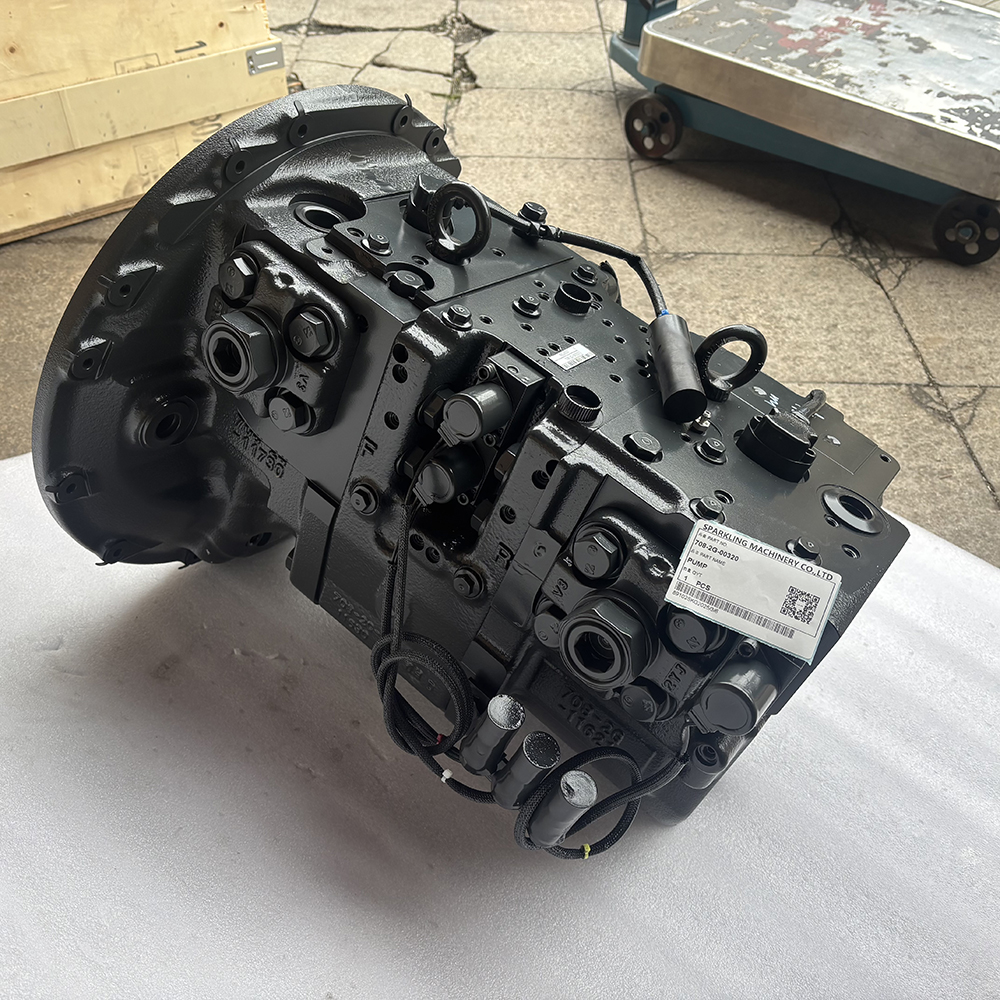

Why quality excavator hydraulic parts and correct sourcing matter

Using quality hydraulic components—pumps, valves, cylinders, seals, and filters—greatly improves reliability. Cheap or mismatched parts can cause cascading failures and higher lifetime costs. For businesses that seek dependable replacements, SPARKLING MACHINERY offers a wide range of excavator hydraulic parts compatible with major brands like Caterpillar, Komatsu, Hitachi, and Volvo. Founded in 2013, SPARKLING MACHINERY focuses on precision manufacturing, strict quality control, customizable solutions, and technical support to help customers reduce costs while ensuring reliability.

Best practices for storage, transport, and winter operation

When storing excavators or spare hydraulic parts, keep components in a clean, dry environment away from UV and extreme temperatures. Use desiccant breathers on open reservoirs. For cold climates, use hydraulic fluids with appropriate low-temperature performance and warm up the system gradually to avoid cold-start damage. Drain and protect unused hydraulic cylinders and valves to prevent corrosion if machines are stored long-term.

Training, documentation, and record-keeping

Operator training reduces misuse and protects hydraulic parts. Maintain clear service records, fluid analysis reports, and parts history. A maintenance log helps identify patterns — for example, repeated pump failures can indicate contamination sources or undersized filtration. Investing in simple digital logs or equipment management systems yields measurable uptime improvements.

When to call a specialist

If symptoms persist after basic checks—such as repeated overheating, unexplained pressure loss, or sudden failures—engage a qualified technician with diagnostic tools (pressure gauges, particle counters, thermal imaging). For major component replacements or calibrations, use quality excavator hydraulic parts and ensure correct installation and testing to avoid warranty issues.

FAQ: Common questions about maintaining excavator hydraulic parts

How often should I change hydraulic oil?

Follow the excavator OEM intervals as the primary guide. Typical practice in mixed-duty applications is to inspect fluid regularly and perform oil changes based on condition or when recommended by the manufacturer. Modern fluids and cleaner systems can allow longer intervals, but only after confirming compatibility and monitoring oil health.

What are the signs of hydraulic contamination?

Symptoms include erratic controls, slower cycle times, increased noise, and shortened component life. Visual indicators are cloudy or dark oil and excessive particulate on filters. Regular sampling and lab analysis give definitive contamination data.

Can I mix hydraulic oils from different brands?

Mixing oils is not recommended unless confirmed compatible with OEM specs and seal materials. In emergencies, top off with a compatible oil, but schedule a full fluid change and analysis soon after.

Are aftermarket excavator hydraulic parts reliable?

High-quality aftermarket parts that meet or exceed OEM specifications can be reliable and cost-effective. Check supplier certifications, material specs, and warranties. Established suppliers like SPARKLING MACHINERY provide quality control, OEM-compatible designs, and technical support.

How can I reduce hydraulic system downtime?

Implement daily checks, correct filtration, scheduled oil and filter changes, operator training, and keep critical spare parts on hand. Use condition monitoring (fluid analysis, particle counters) to predict failures before they happen.

Final takeaway

Longevity of your excavator hydraulic system depends on consistent, practical maintenance: clean fluids, proper filtration, heat control, good hoses and fittings, and timely component replacement. Investing in quality excavator hydraulic parts and partnering with a reliable supplier like SPARKLING MACHINERY helps ensure reliable operation, lower lifecycle costs, and fewer unexpected failures.

What are the application scenarios of Excavator Swing Motor?

Integrating Pressure Sensors into Hitachi Excavator Control Systems

Sparkling Machinery Hub: Features and Installation Tips

Best professional excavator engine overhaul kit manufacturers and supplier brands

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

31E3-3187 Accumulator for Hyundai excavators R140W-9 R170W-7 R180W-9 R210W-9 and Case E18C CX37C

The 31E3-3187 Hydraulic Accumulator is a premium diaphragm-type accumulator engineered for Hyundai wheeled excavators (R140W-9/R170W-7/R180W-9/R210W-9) and Case mini-excavators (E18C/CX37C). It stabilizes hydraulic system pressure, absorbs shock waves, and stores energy for peak-demand operations, preventing component fatigue and extending service life in high-vibration construction environments.

Key Features

· OEM-Matched Precision: 0.35L volume, 31.5MPa max working pressure, and diaphragm design for consistent pressure regulation and energy storage.

· High-Strength Construction: Carbon steel body with anti-corrosion coating and reinforced crimped end caps for 10,000+ hours service in harsh conditions.

· Leak-Proof & Shock-Absorbent: Nitrile rubber diaphragm and O-ring seals eliminate fluid leakage; absorbs pressure spikes up to 42MPa to protect valves/pumps.

· Plug-and-Play Fit: Direct bolt-on mounting with 3/4" NPT port; no modification needed for Hyundai/Case excavator installation.

Compatible Equipment

· Excavators: Hyundai R140W-9, R170W-7, R180W-9, R210W-9; Case E18C, CX37C; also fits Hyundai R200W-7, R170W-9.

· Interchangeable Part Numbers: 31E3-3187, 31MN-90680, 31E33187.

Construction Spare Parts VOE14577744 RELIEF VALVE for Volvo Excavators EC330B EC330C EC340D EC360

SPARKLING MACHINERY NEW EC330B EC330C EC340D EC360B EC380D VOE14577744 Relief Valve is a dedicated, high-precision hydraulic component exclusively engineered for VOLVO EC330B, EC330C, EC340D, EC360B, and EC380D crawler excavators—heavy-duty equipment critical for large-scale mining, construction, and infrastructure projects. As a core safety and pressure-regulating part of the excavator’s hydraulic system, it monitors hydraulic pressure in real time and automatically releases excess pressure to prevent overloading of key components like hydraulic pumps, cylinders, and valves. This function is vital for maintaining stable hydraulic operation during high-intensity tasks such as rock breaking, bulk ore loading, and deep excavation, avoiding pressure-surge damage and ensuring uninterrupted workflow.

Engineered to meet VOLVO’s original equipment (OEM) standards and marked with the genuine part number VOE14577744, the relief valve withstands harsh conditions: high hydraulic pressure (up to 42 MPa), extreme temperature fluctuations (-25°C to 105°C), and continuous heavy-duty vibration. It maintains precise pressure regulation accuracy and resists oil contamination, providing long-lasting reliability for the excavators’ hydraulic systems. Backed by strict performance verification, it guarantees seamless compatibility and operational safety for EC330B/EC330C/EC340D/EC360B/EC380D models.

Rexroth Relief Valve 04950403 R901102333 – 350 Bar Screw‑In Cartridge

The Rexroth Relief Valve 04950403 (part no. R901102333) is a precision-engineered screw-in cartridge valve designed for hydraulic systems in excavators and industrial machinery. This robust, direct-acting spool-type valve offers pressure reducing and relieving capabilities, withstanding up to 350 bar of maximum operating pressure and supporting flow rates around 30 L/min. Constructed with quality materials and standard CAAN cavity compatibility, it ensures responsive, leak-free hydraulic control under demanding conditions.

Premium XKCH-00022 solenoid valve fits Hyundai R125LCR-9A, R145CR9, R160LC9A, and R180LC9S excavators. Reliable hydraulic control part from SPARKLING

The XKCH-00022 Solenoid Valve is a precision-engineered hydraulic control component used in multiple Hyundai crawler excavators, including models R125LCR-9A, R145CR9, R160LC9A, and R180LC9S.

This solenoid valve plays a vital role in directing hydraulic fluid flow in key systems such as travel, swing, or attachment control. Engineered for responsive performance and long-lasting durability, this part ensures accurate actuation and helps maintain overall machine efficiency.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879