Sparkling Machinery Hub: Features and Installation Tips

- Sparkling Machinery Hub: Features and Installation Tips

- Product Overview — Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY

- Why the Hub Is a Critical Excavator Parts Component

- Key Features of the SPARKLING MACHINERY ZGAQ-03591 Hub

- Technical Comparison: Sparkling Hub vs. OEM vs. Generic Aftermarket

- When to Inspect or Replace Your Excavator Hub

- Preparation — Tools, Parts, and Safety Before Installation

- Step-by-Step Installation Guide for the Hub (Best-Practice Workflow)

- Common Installation Pitfalls and How to Avoid Them

- Maintenance Best Practices to Prolong Hub Life

- Brand Advantages: Why Choose SPARKLING MACHINERY for Excavator Parts

- Quality, Compatibility, and Value for Fleet Operators

- FAQ — Common Questions About the Hub and Excavator Parts

- Q1: Is the SPARKLING MACHINERY ZGAQ-03591 hub an exact replacement for Hyundai OEM parts?

- Q2: What warranty and support are available?

- Q3: Can my in-house team install this hub, or do I need a dealer?

- Q4: How often should I inspect the hub after installation?

- Q5: What should I do if I detect noise or play after installation?

- Contact & Call to Action

- References & Sources

Sparkling Machinery Hub: Features and Installation Tips

Product Overview — Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY

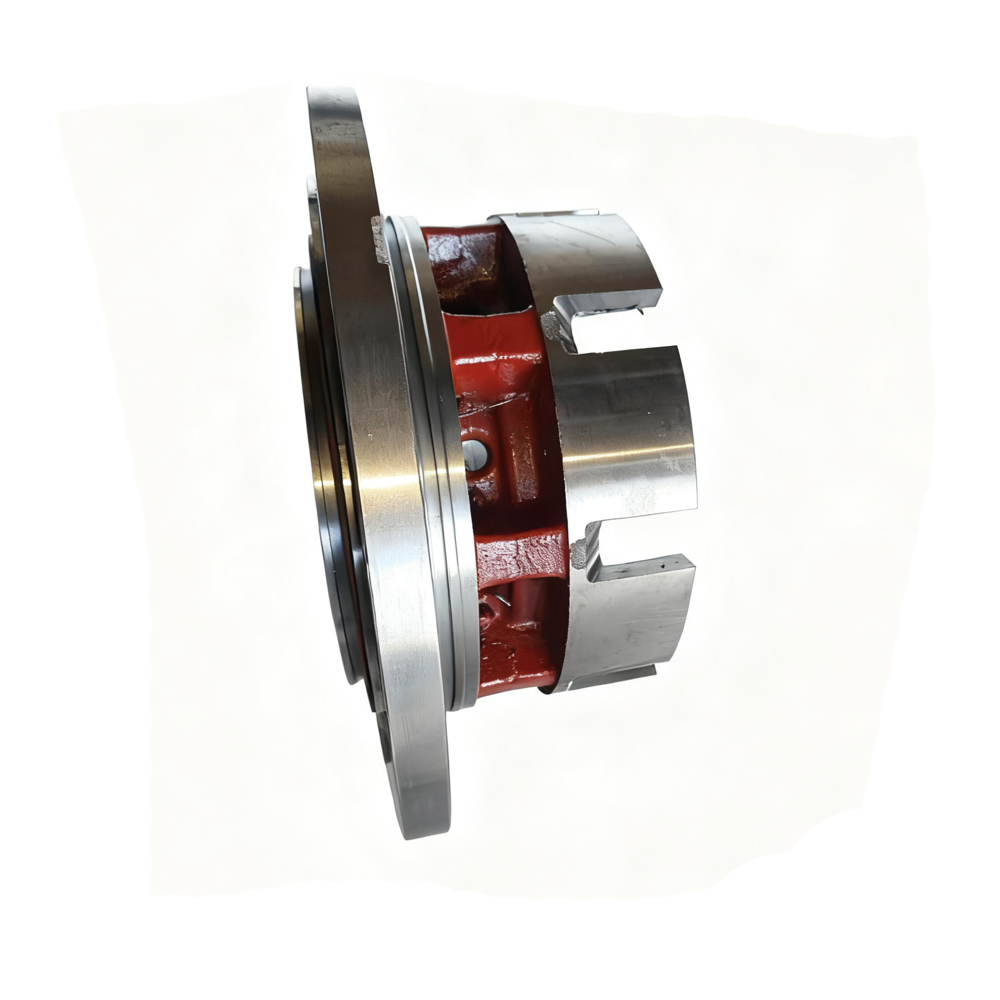

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

This article focuses on practical, professional guidance for procurement, installation, troubleshooting, and maintenance of this hub and other excavator parts. It is written for fleet managers, field technicians, maintenance planners, and purchasing managers who need reliable information to minimize downtime and extend component life.

Why the Hub Is a Critical Excavator Parts Component

The hub is the mechanical interface between the rim/drive sprocket or carrier and the final drive/axle. In wheeled or wheeled-excavator variants, the hub supports radial and axial loads and transmits torque during travel. For tracked systems, a hub-like carrier supports rollers and sprockets. Failure or wear in the hub leads to play in the track, uneven wear on shoes and rollers, vibration, increased fuel consumption, and risk of track derailment. Choosing an excavator parts supplier whose components meet OEM standards (such as ZGAQ-03591 for Hyundai) reduces compatibility issues and short-term replacement frequency.

Key Features of the SPARKLING MACHINERY ZGAQ-03591 Hub

- OEM compatibility: Engineered to meet Hyundai ZGAQ-03591 fit and form for R160W9A/R170W7/R170W7A/R170W9 models.

- Wide operating temperature range: Rated -30°C to 100°C for reliable performance in diverse climates.

- Durability: Heat-treated components and hardened surfaces to resist abrasive wear and impact.

- Precision machining: Tight dimensional tolerances improve seating and reduce runout.

- Sealing and lubrication: Designed for reliable sealing to retain grease and prevent contamination.

- Quality control: Manufactured under controlled processes to meet material and dimensional specs.

Technical Comparison: Sparkling Hub vs. OEM vs. Generic Aftermarket

Below is a concise comparison of key attributes typically considered when selecting excavator parts hubs. Values are representative based on product literature and industry practice; always verify with OEM manuals and supplier test reports.

| Attribute | SPARKLING MACHINERY ZGAQ-03591 Hub | Hyundai Genuine (OEM) | Generic Aftermarket |

|---|---|---|---|

| Fit/Compatibility | Designed to meet ZGAQ-03591; direct fit for specified models | Guaranteed direct fit per factory serial/model | Varies; fitment often requires verification |

| Material & Heat Treatment | Hardened alloy steel, controlled heat treatment | Factory-specified grade and process | Inconsistent; may use lower-grade steels |

| Operating Temp Range | -30°C to 100°C (product spec) | Designed for wide operating ranges per model | Depends on material; often narrower range |

| Wear & Impact Resistance | Engineered for heavy-duty use | Highest standard for longevity | Lower; may show faster degradation |

| Warranty & Support | Supplier warranty and technical support options | Factory warranty and dealer support | Limited or none |

Sources for comparative attributes: manufacturer product literature (SPARKLING MACHINERY), Hyundai parts catalogs/technical manuals, and industry evaluations of aftermarket components.

When to Inspect or Replace Your Excavator Hub

Proactive inspection prevents expensive downtime. Inspect the hub when you notice:

- Unusual vibration or noise during travel or slewing.

- Visible grease leakage or contamination around seals.

- Excessive play or axial movement in the wheel or carrier.

- Uneven track or tire wear that indicates misalignment.

- After impact events (strike by heavy object, roll-over), even when no visible damage is present.

Carry out a visual and hands-on inspection every 250–500 operating hours or per your machine maintenance schedule. Record findings and compare with prior inspections to detect progressive wear.

Preparation — Tools, Parts, and Safety Before Installation

Preparation reduces errors and safety risks. Required items typically include:

- Service manual for the specific Hyundai model (R160W9A/R170W7/R170W7A/R170W9) — for torque specs and removal sequence.

- Appropriate lifting equipment (hydraulic crane, jack) rated above the machine’s partial weight.

- Torque wrenches calibrated to the required range.

- Seal drivers, bearing pullers, drift pins, alignment tools.

- Recommended grease and sealant per OEM or supplier guidance.

- Personal protective equipment (PPE): safety glasses, gloves, steel-toe boots, and hearing protection.

- Clean workspace and parts trays for fasteners and small components.

Always lock out the machine electrical system and follow safe jacking/lifting procedures. If you do not have trained technicians, arrange qualified service to perform the installation.

Step-by-Step Installation Guide for the Hub (Best-Practice Workflow)

Note: This workflow is a general best-practice guide. Always follow the Hyundai service manual for your machine for exact steps, torque values, and safety warnings.

- Secure machine and remove power. Block wheels and lower attachments to stabilize the excavator.

- Lift the machine or wheel assembly so the track/tire is free of ground load. Use rated lifting gear.

- Remove track or wheel assembly components to access the hub mounting points. Label fasteners and components to ensure correct reassembly order.

- Clean the mounting area. Inspect the axle shaft, seals, splines, and mating surfaces for damage or corrosion. Replace seals or damaged components before installing the new hub.

- Remove the old hub using appropriate pullers and supports. Avoid prying on seals or bearing races.

- Inspect bearings and races. If bearings show wear, replace them per OEM guidance. Clean bearing bores thoroughly.

- Test-fit the SPARKLING MACHINERY hub to ensure correct seating and alignment. If interference is detected, inspect for burrs or contamination.

- Apply recommended lubricant or anti-seize to mounting surfaces as specified. Many installations require specific greases; use only those recommended by Hyundai or the part supplier.

- Install the hub and fasten hardware hand-tight to align components. Gradually tighten in a star pattern to specified torque values from the service manual.

- Reinstall the track/wheel assembly. Set track tension per the machine manual to avoid excessive axial load on the hub.

- Lower the machine and perform a dynamic test: rotate the machine, travel at low speed, and listen for noise. Re-check torques after initial operation hours as per OEM break-in procedure.

Critical installation notes: always use OEM torque values where provided and replace any single-use fasteners or cotter pins. Never operate a machine with an unverified installation.

Common Installation Pitfalls and How to Avoid Them

- Improper cleaning: Contaminants trapped under the hub can cause misalignment. Always clean mating surfaces with solvent and lint-free cloths.

- Wrong lubricant: Using incorrect grease can lead to seal degradation. Confirm grease type and NLGI grade with supplier documentation.

- Under/over-torquing: Both can lead to premature failure. Calibrate your torque wrench regularly and follow the specified pattern.

- Reusing worn seals/bearings: Replace when in doubt — the marginal cost of new seals is small compared to downtime from failure.

- Skipping break-in checks: Re-torque checks after initial service hours catch settling and prevent loosening in field operation.

Maintenance Best Practices to Prolong Hub Life

Follow these practices to maximize service life of your excavator parts, including the hub:

- Scheduled inspections: visual check every shift; detailed inspection every 250–500 hours.

- Maintain correct track tension and alignment to reduce uneven loads.

- Keep seals and grease points clean; protect greaser fittings from dirt ingress.

- Record all replacements and observations in a machine maintenance log to detect wear trends early.

- Train operators on proper machine use — avoid aggressive maneuvers that place shock loads through the undercarriage.

Brand Advantages: Why Choose SPARKLING MACHINERY for Excavator Parts

Quality, Compatibility, and Value for Fleet Operators

SPARKLING MACHINERY positions its ZGAQ-03591 hub as an OEM-compatible, heavy-duty excavator parts solution for Hyundai R160W9A/R170W7/R170W7A/R170W9 models. Key brand advantages include:

- Strict manufacturing controls and material selection to meet OEM geometry and performance expectations.

- Competitive pricing compared with factory parts while providing direct-fit compatibility.

- After-sales technical support and parts traceability to help maintenance teams diagnose issues quickly.

- Design focus on wear resistance and reliable sealing to extend service intervals and reduce total cost of ownership.

For purchasing managers, the balance between upfront cost and lifecycle performance is critical. SPARKLING MACHINERY aims to deliver components that reduce unscheduled downtime without substantially increasing initial part cost.

FAQ — Common Questions About the Hub and Excavator Parts

Q1: Is the SPARKLING MACHINERY ZGAQ-03591 hub an exact replacement for Hyundai OEM parts?

A1: The hub is engineered to meet Hyundai ZGAQ-03591 specifications and designed for direct fit on R160W9A/R170W7/R170W7A/R170W9 models. Verify part numbers and machine serial numbers before purchase. For absolute factory warranty considerations, consult your Hyundai dealer.

Q2: What warranty and support are available?

A2: Warranty terms vary by distributor and region. SPARKLING MACHINERY typically offers supplier warranties and technical support; confirm terms at time of purchase.

Q3: Can my in-house team install this hub, or do I need a dealer?

A3: Trained maintenance teams with appropriate tools and access to the Hyundai service manual can perform installation. For complex cases or if warranty coverage requires dealer installation, coordinate with an authorized service provider.

Q4: How often should I inspect the hub after installation?

A4: Perform a visual inspection daily or per shift for leaks and abnormal behavior. Conduct a more thorough inspection every 250–500 operating hours, and re-torque checks during initial break-in per service manual guidelines.

Q5: What should I do if I detect noise or play after installation?

A5: Immediately secure the machine, check torque on mounting hardware, inspect seals and mating surfaces for contamination, and verify bearing condition. If problems persist, remove the hub for detailed inspection and contact the supplier or an authorized technician.

Contact & Call to Action

For pricing, availability, or technical support for the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub and other excavator parts, contact our sales team or view the product page. Our specialists can provide compatibility confirmation, delivery estimates, and installation guidance tailored to your fleet. After installing Sparkling Machinery hubs, it’s crucial to understand the top signs your excavator needs a hub replacement. Recognizing these early warning signs can save you from costly repairs and downtime, ensuring your excavator continues operating at peak efficiency.

Contact us: Email: sales@example.com | Phone: +1-800-EXCAV8 (example). View product: /products/sparkling-machinery-zgaq-03591-hub (example link).

References & Sources

- Hyundai Construction Equipment — Official Parts Catalogs and Service Manuals (Hyundai dealer documentation).

- SPARKLING MACHINERY product literature and technical specifications (supplier datasheets).

- Industry standards and best practices for heavy equipment maintenance — SAE International and ISO maintenance guidance documents.

- Field maintenance guides and articles from construction equipment industry publications (e.g., Construction Equipment Guide).

How Hyundai R170W7 Parts Improve Machine Performance

Top Specs: YN52S00102P1 Low Pressure Sensor for SK250-6E/8

Buying Guide: Genuine vs OEM Parts of Excavator 2026

Best professional heavy equipment parts manufacturers and supplier brands

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879