How Hyundai R170W7 Parts Improve Machine Performance

- How Hyundai R170W7 Parts Improve Machine Performance

- Understanding the role of high-quality excavator parts in overall machine performance

- Product overview: SPARKLING MACHINERY NEW R160W9A R170W7 Hub (ZGAQ-03591)

- Why the hub matters: load distribution, travel stability and safety

- How Hyundai R170W7 parts specifically improve performance

- 1. Greater wear resistance and predictable lifespan

- 2. Better temperature resilience

- 3. Improved impact resistance

- Engineering features of the SPARKLING MACHINERY ZGAQ-03591 Hub

- Field performance and maintenance advantages

- Practical maintenance outcomes

- Comparative performance table: ZGAQ-03591 Hub vs Generic Aftermarket Hub

- Installation, inspection and best-practice tips

- Lifecycle cost and ROI: why higher-quality excavator parts can be cheaper long-term

- Brand advantages: Why choose SPARKLING MACHINERY Hyundai-compatible parts

- FAQ — Common questions about Hyundai R170W7 parts and the ZGAQ-03591 Hub

- Q: Is the SPARKLING MACHINERY ZGAQ-03591 Hub a direct OEM part?

- Q: How does the hub rating (-30°C to 100°C) affect field performance?

- Q: What maintenance should we perform after installing a new hub?

- Q: Will using this hub affect my machine’s warranty?

- Q: How do I choose between OEM-branded and high-quality OEM-standard aftermarket parts?

- Contact us / View product

- Sources

How Hyundai R170W7 Parts Improve Machine Performance

Understanding the role of high-quality excavator parts in overall machine performance

For construction and mining operations, the reliability of excavator parts directly affects uptime, safety, and operating cost. Undercarriage components such as hubs, idlers, rollers, and sprockets transfer loads, control track travel, and absorb impacts from rough terrain. Selecting high-quality, OEM-standard excavator parts—for example, components built to Hyundai specifications—reduces unexpected failures and delivers predictable performance over the machine’s service life. This article focuses on the Hyundai-compatible SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub and explains how that part improves machine performance in practical terms.

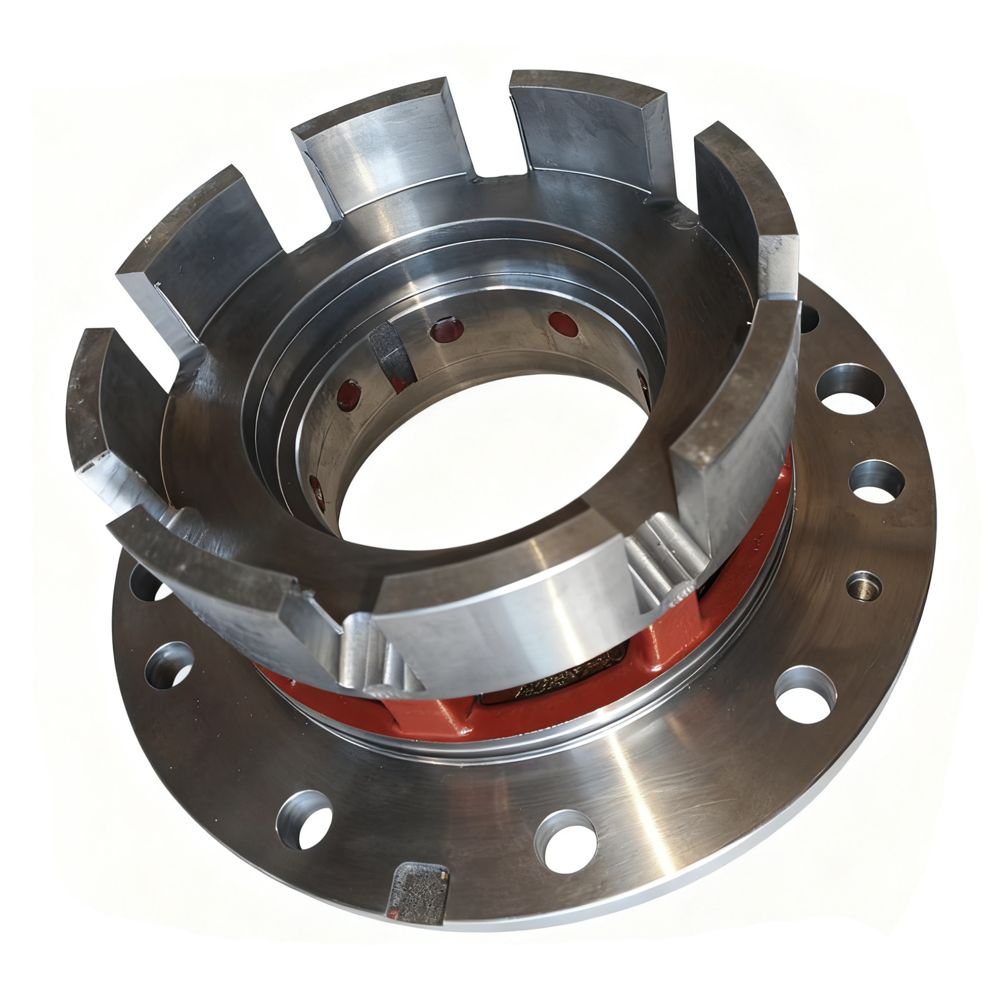

Product overview: SPARKLING MACHINERY NEW R160W9A R170W7 Hub (ZGAQ-03591)

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Why the hub matters: load distribution, travel stability and safety

The hub is the mechanical interface between the wheel/axle assembly and the tracks. When the hub functions correctly it ensures even load distribution across the undercarriage and minimizes lateral play in the axle-track connection. Benefits of a properly specified hub include:

- Improved travel stability on uneven ground, reducing track derailments and operator interventions.

- Even wear distribution on rollers and track links, extending the service life of multiple excavator parts.

- Reduced vibration and shock transmitted to the chassis and hydraulic systems, lowering fatigue-related failures.

How Hyundai R170W7 parts specifically improve performance

Hyundai R170W7-specific parts—designed to Hyundai OEM tolerances and material specs—bring measurable advantages for machines operating in tough conditions. The SPARKLING MACHINERY ZGAQ-03591 Hub is engineered to meet those OEM standards. Key performance improvements include:

1. Greater wear resistance and predictable lifespan

Materials and heat-treatment processes used in OEM-standard hubs increase hardness in critical bearing and sealing surfaces without compromising toughness. That translates to slower wear of contact points and seals, which keeps tolerances tighter over more operating hours and reduces unscheduled replacements.

2. Better temperature resilience

The ZGAQ-03591 Hub is rated for -30°C to 100°C. In extreme cold, brittle failures and seal hardening are common with inferior parts; in high-ambient or heavy-duty working conditions, thermal expansion and lubricant breakdown accelerate wear. A hub specified for a wide operating temperature range maintains seals and bearings within design clearances, reducing leak and bearing-failure risks.

3. Improved impact resistance

Construction and quarry environments expose undercarriage components to repeated impacts. OEM-grade hubs are designed with controlled microstructure and surface treatments that increase resistance to impact-driven cracks and spalling. Less micro-damage leads to more predictable maintenance intervals and fewer catastrophic failures.

Engineering features of the SPARKLING MACHINERY ZGAQ-03591 Hub

Understanding the engineering behind a hub helps explain the practical uptime benefits. The SPARKLING MACHINERY hub includes:

- Dimensional compatibility with Hyundai R160W9A/R170W7 series axles—ensures bolt patterns, bore tolerances and bearing fits match OEM drawings.

- Heat-treated bearing seats and machined sealing surfaces—support longevity of bearings and reduce lubricant leakage.

- Material selection tuned for combined strength and toughness—balances wear resistance and impact absorption.

- Surface coatings or treatments that improve corrosion resistance and reduce fretting between mating parts.

Field performance and maintenance advantages

On job sites, the right hub affects multiple maintenance vectors:

- Reduced downtime due to fewer seal or bearing failures leads to higher fleet availability.

- Simplified diagnostics—OEM-compatible geometry reduces the likelihood of secondary failures caused by dimension mismatch (misalignment, unusual wear patterns).

- Lower long-term inventory complexity—standardized OEM-compatible parts allow operators to stock fewer unique items while covering multiple machine variants.

Practical maintenance outcomes

Technicians frequently report that machines fitted with OEM-standard undercarriage components exhibit more consistent wear patterns and require fewer emergency repairs. That consistency allows maintenance managers to move from reactive to predictive maintenance schedules, improving labor planning and reducing overtime.

Comparative performance table: ZGAQ-03591 Hub vs Generic Aftermarket Hub

| Attribute | SPARKLING MACHINERY ZGAQ-03591 Hub (OEM standard) | Generic Aftermarket Hub |

|---|---|---|

| Compatibility | Direct fit for Hyundai R160W9A/R170W7 series (ZGAQ-03591) | Varies—may require rework or adapters |

| Operating temperature rating | -30°C to 100°C (manufacturer stated) | Often unspecified or narrower range |

| Material & heat treatment | Specified to meet OEM mechanical properties | Often inconsistent between batches |

| Expected fit-and-function | High—designed to OEM tolerances | Variable; risk of misfit |

| Warranty & traceability | Often provided and traceable to production batch | Limited or no warranty, limited traceability |

Source for OEM spec: product description provided by manufacturer; general aftermarket behavior summarized from industry maintenance publications and manufacturer guidance (see sources at article end).

Installation, inspection and best-practice tips

To maximize the performance benefits of the ZGAQ-03591 Hub and similar high-quality excavator parts, follow these recommendations:

- Use qualified technicians familiar with Hyundai undercarriage assemblies to ensure proper torque, bearing preload and seal seating.

- Inspect seals and bearing surfaces for contamination at installation; replace associated bearings and seals if wear is detected.

- Run-in new hubs under light load initially, then inspect for leaks and abnormal noise after the first 10-20 operating hours.

- Adopt a condition-based inspection schedule (visual checks, lubricant analysis, vibration when feasible) to detect early signs of wear.

Lifecycle cost and ROI: why higher-quality excavator parts can be cheaper long-term

Initial purchase price is only one factor in parts economics. Consider total cost of ownership (TCO): part cost, downtime cost per hour, labor for replacement, and collateral damage from failure (e.g., damaged track links or bearings). High-quality, OEM-standard parts like the ZGAQ-03591 Hub typically reduce unplanned downtime, which in many fleets represents the largest single cost driver.

Example considerations:

- Reduced emergency callouts and overtime repairs.

- Lower likelihood of secondary damage to adjacent components.

- More predictable maintenance scheduling, improving machine utilization.

When these benefits are quantified for a busy fleet, improved uptime and fewer secondary repairs usually outweigh a modest High Quality on part cost.

Brand advantages: Why choose SPARKLING MACHINERY Hyundai-compatible parts

In the latter half of your decision process, brand matters. SPARKLING MACHINERY positions its R160W9A/R170W7-series hub as a high-quality, China-manufactured component that meets Hyundai OEM standard ZGAQ-03591. Brand advantages include:

- OEM-standard compliance—designs verified to match Hyundai dimensional and performance criteria.

- Manufacturing controls—consistent material and heat-treatment processes that reduce batch-to-batch variability.

- Cold and heat tolerance suitable for a wide range of climates (-30°C to 100°C rating).

- Traceability and batch documentation that support warranty claims and quality audits.

Combined, these strengths make SPARKLING MACHINERY hubs a practical choice for operators seeking reliable excavator parts that deliver predictable lifecycle performance while remaining cost-competitive.

FAQ — Common questions about Hyundai R170W7 parts and the ZGAQ-03591 Hub

Q: Is the SPARKLING MACHINERY ZGAQ-03591 Hub a direct OEM part?

A: The hub is manufactured to meet Hyundai OEM standard ZGAQ-03591 and is designed for direct compatibility with Hyundai R160W9A/R170W7/R170W7A/R170W9 models. It is a high-quality aftermarket part made to OEM tolerances (not an original Hyundai-branded part).

Q: How does the hub rating (-30°C to 100°C) affect field performance?

A: That temperature range indicates materials and seals were selected to maintain mechanical properties across typical extreme working temperatures. It reduces the risk of brittle fracture in cold climates and seal/lubricant degradation in hot environments, supporting reliable operation.

Q: What maintenance should we perform after installing a new hub?

A: Perform a post-installation inspection after the first 10–20 operating hours, check for leaks, unusual noise or heat, and re-torque fasteners per Hyundai torque specifications. Maintain routine inspections focusing on seals, bearing condition and lubricant cleanliness.

Q: Will using this hub affect my machine’s warranty?

A: If your machine is under OEM warranty, consult Hyundai or your dealer before installing non-Hyundai-branded parts; policies vary by region and warranty terms. For out-of-warranty machines, the hub provides OEM-standard compatibility and traceability.

Q: How do I choose between OEM-branded and high-quality OEM-standard aftermarket parts?

A: Evaluate total cost of ownership, supplier traceability, batch documentation, warranty terms and local support. High-quality aftermarket parts that meet OEM standards often provide comparable performance at a lower price when sourced from reputable manufacturers with quality controls.

Contact us / View product

If you want to improve your fleet reliability with OEM-standard excavator parts, contact our sales team to discuss compatibility, pricing, and availability of the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub. Our specialists can provide technical sheets, batch certificates, and fitment guidance to ensure a smooth installation and fast return to service. As you explore the performance benefits of Hyundai R170W7 parts, it’s also important to recognize common hub problems and how technicians diagnose them. Identifying these issues early will prevent damage to your equipment and reduce repair costs in the long term.

Contact our parts department today to request a quote or technical datasheet, or visit our product page to order genuine-quality Hyundai R170W7 excavator parts.

Sources

- Product specification provided by SPARKLING MACHINERY (manufacturer product description included in this article).

- Hyundai Construction Equipment — official manuals and parts compatibility guidance (manufacturer service literature and parts catalogs).

- Caterpillar Maintenance Guides — general undercarriage wear, inspection and maintenance best practices (industry standard references for heavy equipment maintenance procedures).

- Industry maintenance analyses and fleet-management whitepapers on total cost of ownership for heavy machinery (professional publications and fleet case studies).

Note: For specific technical datasheets, torque values, and installation procedures consult the Hyundai service manual for your machine model or request OEM standard drawings and certificates from the supplier before installation.

How Excavator Hydraulic Systems Contribute to Fuel Efficiency

Sensor Integration with Hydraulic Components in 2026

The B2B Buyer’s Guide to Excavator Attachments

Wholesale heavy machinery rear axle manufacturer and supplier

faq

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879