Parts of an Excavator: Buying Guide for Hyundai HW210

- Understanding Key Components and Their Functions

- Upperstructure: engine, hydraulic system and cab

- Working group: boom, arm, bucket and pins

- Undercarriage: tracks, rollers, sprockets and final drives

- Critical Wear Parts and Replacement Guide

- Bearings and seals: why tapered roller bearings matter

- Hydraulic cylinders and hoses: inspection and replacement intervals

- Final drives, travel motors and track components

- Buying Guide: Selecting Parts for Hyundai HW210 and Related Models

- Compatibility: HW210, R200W7, R200W7A, R210W-9

- OEM vs aftermarket: what to choose

- Supplier and warranty considerations

- Maintenance Best Practices and Brand Advantages

- Routine checks and recommended replacement schedule

- Why choose SPARKLING MACHINERY ZGAQ-02328 and Hyundai OEM standards

- Where to buy and what to ask

- Application Examples, Common Failure Modes and Troubleshooting

- Common failure symptoms for bearings and their root causes

- Case example: swing bearing failure progression

- Practical inspection checklist for field technicians

- FAQ — Frequently Asked Questions

- Q: Is the ZGAQ-02328 tapered roller bearing an OEM part for Hyundai excavators?

- Q: Can I replace my excavator’s tapered roller bearing myself?

- Q: How do I know if my HW210 needs a new bearing?

- Q: What is the difference between OEM and aftermarket bearings?

- Q: How often should I change final drive oil and check bearings?

- Q: Where can I find official Hyundai parts information?

This guide covers the key parts of an excavator and practical buying advice for Hyundai HW210 series machines (including R200W7, R200W7A and R210W-9). It highlights the ZGAQ-02328 tapered roller bearing by SPARKLING MACHINERY — a core rotating component meeting Hyundai OEM standards — and explains how to choose, inspect and maintain critical components to maximize uptime and reduce life-cycle cost. The content is written for purchasers, service managers and technicians who need reliable, actionable information for parts selection and maintenance planning.

Understanding Key Components and Their Functions

Upperstructure: engine, hydraulic system and cab

The upperstructure houses the engine, hydraulic pumps, control valves and the cab — effectively the power and control center of the excavator. The engine produces mechanical energy that the hydraulic pumps convert to hydraulic power. Key parts of an excavator in this group include the engine block, fuel system, air intake and exhaust components, hydraulic pumps, hydraulic oil cooler and the machine’s electronic control unit (ECU). Proper filtration, coolant and hydraulic oil maintenance here directly affect responsiveness and component life.

Working group: boom, arm, bucket and pins

The boom, arm (stick) and bucket form the working group or front linkage. Pins, bushings and the hydraulic cylinders that drive them are high-wear items. Correctly sized pins and hardened bushings preserve geometry and digging efficiency. Understanding the load paths and how combined radial and axial stresses transfer through the boom and arm helps determine which parts (for example, swing bearings and taper roller bearings) are critical for replacement before secondary damage occurs.

Undercarriage: tracks, rollers, sprockets and final drives

The undercarriage supports weight and transmits travel forces to the ground. Main parts of an excavator here include track chains, track pads, carrier rollers, track rollers, idlers, sprockets and the final drive (planetary gearbox). Excessive wear or misalignment accelerates wear of rollers and sprockets; replacing only a single part (e.g., sprocket) without addressing worn chain or rollers can reduce service life and increase cost. Final drive failures often result from contamination or bearing failure within the gearbox—making seals and bearings critical maintenance points.

Critical Wear Parts and Replacement Guide

Bearings and seals: why tapered roller bearings matter

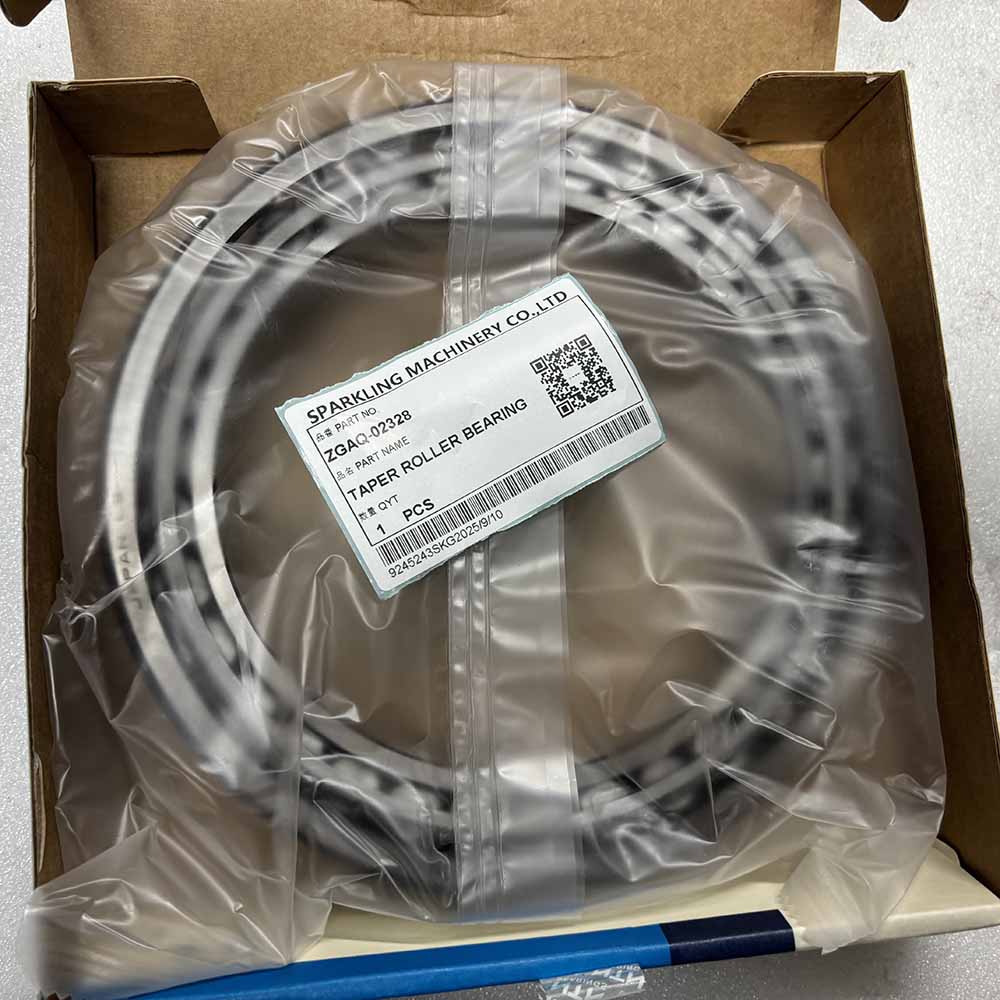

Bearings convert relative motion between parts into controlled rotation and carry radial and axial loads. On excavators, tapered roller bearings are used where combined radial and axial loads occur — for example, in swing drives, final drives or key shaft interfaces. The SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is designed as a core rotating component for Hyundai excavators used in construction and mining. It withstands combined radial and axial loads, ensuring smooth rotation of key shaft parts.

SPARKLING MACHINERY NEW ZGAQ-02328 Taper Roller Bearing is a core rotating component for Hyundai excavators (construction/mining use). It withstands combined radial and axial loads, ensuring smooth rotation of key shaft parts. Meeting Hyundai OEM standards (Part No.: ZGAQ-02328), it delivers high wear resistance and load capacity, guaranteeing seamless compatibility and long-term stable operational performance.

Tapered roller bearings are sensitive to installation angle, preload and alignment. Incorrect preloading or contamination from degraded seals is a common failure cause. For technical background on tapered roller bearings and load behavior see the tapered roller bearing overview on Wikipedia: https://en.wikipedia.org/wiki/Tapered_roller_bearing.

Hydraulic cylinders and hoses: inspection and replacement intervals

Hydraulic cylinders translate hydraulic pressure into linear force and motion. Common failure modes include seal wear, piston rod corrosion and internal leakage. Hoses and fittings can suffer abrasion and cracking. Routine checks should include visual hose inspection, pressure testing and checking for external oil leaks. Replace hoses based on visual degradation or manufacturer-recommended intervals; for cylinders, replace seals during scheduled rebuilds or if leakage/slow operation is observed.

Final drives, travel motors and track components

Final drives and travel motors incorporate bearings, seals and gears under heavy loads and contamination risk. Monitor oil contamination via periodic oil analysis and replace final drive oil at recommended intervals. Track chain wear should be measured and compared against OEM limits; excessive elongation causes accelerated sprocket wear and track slippage. Regularly inspect and replace track rollers, idlers and sprockets as a linked set where practical to reduce mismatched wear.

Buying Guide: Selecting Parts for Hyundai HW210 and Related Models

Compatibility: HW210, R200W7, R200W7A, R210W-9

Hyundai’s model family shares many components across similar series, but variations in configuration (e.g., wheeled vs. tracked, series updates) change part numbers. When selecting parts of an excavator for HW210, confirm machine serial number and submodel. The ZGAQ-02328 bearing lists compatibility with Hyundai models including HW210 and the R200/R210 series — but always verify using the machine’s parts manual or OEM parts lookup to ensure fitment. OEM parts catalogs and serial-number lookup are authoritative; Hyundai’s parts portals are useful for confirmation: Hyundai Construction Equipment.

OEM vs aftermarket: what to choose

Choosing OEM parts generally ensures exact fit, tested performance and warranty support. High-quality aftermarket parts (like SPARKLING MACHINERY’s ZGAQ-02328 when specified to OEM standards) can offer cost savings while meeting performance needs if they clearly state compatibility and quality assurance. Evaluate aftermarket suppliers on technical documentation, material specifications, heat treatment, finish, tolerance data and third-party testing. Consider application severity: for mining or high-duty cycles, OEM or certified equivalent parts reduce risk of unexpected failure.

Supplier and warranty considerations

Buy from authorized dealers or reputable reman/aftermarket vendors that provide warranty, traceability and technical support. Check for: part number traceability, batch/lot testing documentation, a clear return policy, and the ability to provide technical drawings or certificates of conformity. Where possible, select suppliers who offer installation guidance or warranty coverage that aligns with your operational risk tolerance.

Maintenance Best Practices and Brand Advantages

Routine checks and recommended replacement schedule

Preventive maintenance is the most cost-effective approach to extending component life. A sample maintenance table for key parts is shown below to guide scheduling — adapt intervals to duty cycle, environment and OEM recommendations.

| Component | Typical Check Interval | Key Inspection Points |

|---|---|---|

| Engine oil & filter | 250–500 hours | Oil level/color, filter condition, signs of contamination |

| Hydraulic oil & filter | 1,000–2,000 hours (or oil analysis) | Viscosity, contamination particle count, water content |

| Final drive oil | 500–1,000 hours | Oil level, contamination, metal particles |

| Tapered roller bearings (swing, shafts) | Inspect at 1,000 hours or during major service | Noise, play, temperature rise, lubrication condition |

| Track & undercarriage | 500 hours | Track tension, wear measurements, rollers and idlers condition |

| Hydraulic hoses & cylinders | 250–500 hours | External leaks, hose abrasion, rod corrosion |

Use oil analysis to guide hydraulic and gearbox oil change intervals — it is often more cost-effective than fixed schedules and detects early contamination that shortens bearing life.

Why choose SPARKLING MACHINERY ZGAQ-02328 and Hyundai OEM standards

The SPARKLING MACHINERY ZGAQ-02328 taper roller bearing is presented as meeting Hyundai OEM standards (Part No.: ZGAQ-02328). Key advantages when a part aligns with OEM standards include straightforward fitment, validated load capacity and lifecycle expectations, and reduced risk of warranty complications compared with non-specified or unverified parts. When a critical rotating part like a tapered roller bearing matches OEM tolerances, you gain predictable preload behavior, accurate contact patterns and improved resistance to wear under combined loads.

Brand advantages to evaluate when selecting parts and suppliers:

- OEM conformity or documented equivalence to OEM specs.

- Material traceability and heat-treatment records.

- Field support, warranty and parts return policies.

- Availability of technical data and fitment confirmation for models HW210, R200W7, R200W7A and R210W-9.

Where to buy and what to ask

When purchasing parts of an excavator, request the following from suppliers:

- Exact part number match or OEM cross-reference (e.g., ZGAQ-02328).

- Material certificates and inspection reports.

- Warranty terms and repair/return processes.

- Installation guidance or torque/preload values for bearings.

Application Examples, Common Failure Modes and Troubleshooting

Common failure symptoms for bearings and their root causes

Typical symptoms of bearing distress include increased operating temperature, unusual noise (grinding or rumbling), vibration and increased play. Root causes are usually lubrication breakdown, contamination (water or abrasive particles), misalignment, improper preload or fatigue from overloading. Regular monitoring with infrared temperature checks and vibration analysis can detect early stages of failure.

Case example: swing bearing failure progression

A swing bearing showing initial pitting due to water ingress, if left unaddressed, will develop localized spalling that increases cyclic stress in adjacent rollers and raceways. This can quickly progress to catastrophic seizure and damage to axle/shank components. Early replacement of a worn bearing like ZGAQ-02328 when pitting is detected prevents secondary gearbox or shaft damage and significantly reduces repair downtime and cost.

Practical inspection checklist for field technicians

Field checks that prevent failures:

- Daily: visual hydraulic leak check, track tension, and walk-around for loose bolts.

- Weekly: grease fittings, swing bearing lubrication check, visual bearing inspection for grease condition.

- Monthly: oil sample for hydraulic and final drive systems; check bearing temps after operation.

FAQ — Frequently Asked Questions

Q: Is the ZGAQ-02328 tapered roller bearing an OEM part for Hyundai excavators?

A: The ZGAQ-02328 is presented as meeting Hyundai OEM standards and lists Hyundai part number ZGAQ-02328 for compatibility. Always confirm using your machine’s serial number and the OEM parts manual before installation.

Q: Can I replace my excavator’s tapered roller bearing myself?

A: Replacing tapered roller bearings requires correct tools, clean environment, correct preload settings and alignment. For bearings on critical shafts or swing components, professional installation or supervision is recommended to ensure correct preload and avoid premature failure.

Q: How do I know if my HW210 needs a new bearing?

A: Look for increased noise, vibration, elevated operating temperature, or visible play in the assembly. Oil analysis showing metal particles and visual inspection for pitting are also indicators. If in doubt, schedule a bearing inspection and non-destructive testing where possible.

Q: What is the difference between OEM and aftermarket bearings?

A: OEM bearings are produced to the manufacturer’s exact specifications and often come with parts documentation and warranty coverage. Aftermarket bearings may vary in materials, tolerances and manufacturing processes. Quality aftermarket bearings that provide material certifications and test reports can be acceptable substitutes when they demonstrate OEM-level performance.

Q: How often should I change final drive oil and check bearings?

A: Final drive oil is commonly checked at 500–1,000 hours depending on operating conditions; however, oil analysis is a better method to determine actual replacement intervals. Bearings should be inspected during major services (e.g., 1,000 hours) and whenever symptoms such as noise or heat are detected.

Q: Where can I find official Hyundai parts information?

A: Official parts information is available from Hyundai Construction Equipment’s parts portals and parts manuals. For general excavator technical overviews, see the Excavator article on Wikipedia: https://en.wikipedia.org/wiki/Excavator. For bearing technical details, consult the tapered roller bearing entry: https://en.wikipedia.org/wiki/Tapered_roller_bearing.

If you have more questions or need help confirming compatibility for HYUNDAI EXCAVATOR PARTS HW210 R200W7 R200W7A R210W-9 ZGAQ-02328 TAPER ROLLER BEARING SPARKLING MACHINERY, contact our parts specialists for serial-number lookup, pricing and lead times. Click to contact customer service or view the product listing for availability and technical sheets.

Contact / View Product: For assistance ordering ZGAQ-02328 or other parts of an excavator compatible with Hyundai HW210 and related models, please contact our sales team or view the product page to request a quote and technical documentation.

Understanding Wear Patterns on Excavator Hubs

The B2B Buyer’s Guide to Hydraulic Systems for Excavators

Wholesale excavator switch column manufacturer and supplier

Case Studies of Hydraulic Component Upgrades in 2026

faq

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879