Common Causes of Hydraulic Pump Failures and Fixes

- Common Causes of Hydraulic Pump Failures and Fixes

- Why hydraulic pump reliability matters for hydraulic system components

- Overview of the Lingong HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B0610-54010 HYDRAULIC PUMP SPARKLING MACHINERY

- Common failure categories for hydraulic pumps

- 1. Contamination: solid particles and water

- 2. Cavitation and aeration

- 3. Overheating and thermal degradation

- 4. Wear and internal damage (abrasive and fatigue)

- 5. Incorrect hydraulic fluid and contamination by incompatible additives

- 6. Mechanical alignment, mounting and shaft coupling issues

- 7. Pressure spikes and shock loads

- Troubleshooting and diagnostic table for hydraulic pump failures

- Inspection checklist for hydraulic pumps and hydraulic system components

- Why choosing the correct pump matters: advantages of the NEW B0610-54010 Hydraulic Pump

- Practical maintenance program to reduce pump failures

- When to repair vs. replace hydraulic pumps

- FAQ (Frequently Asked Questions)

- Contact us / View product

- Authoritative references and further reading

- Final notes

Common Causes of Hydraulic Pump Failures and Fixes

Why hydraulic pump reliability matters for hydraulic system components

Hydraulic pumps are the heart of many heavy-duty machines. On excavators, loaders, and other construction equipment, pumps convert mechanical power into hydraulic energy that drives arms, booms, swing and travel systems. Failures in hydraulic pumps cause costly downtime, unsafe operation, and premature wear of downstream components. Understanding the root causes and proven fixes helps maintenance teams keep machines running and reduce life-cycle costs.

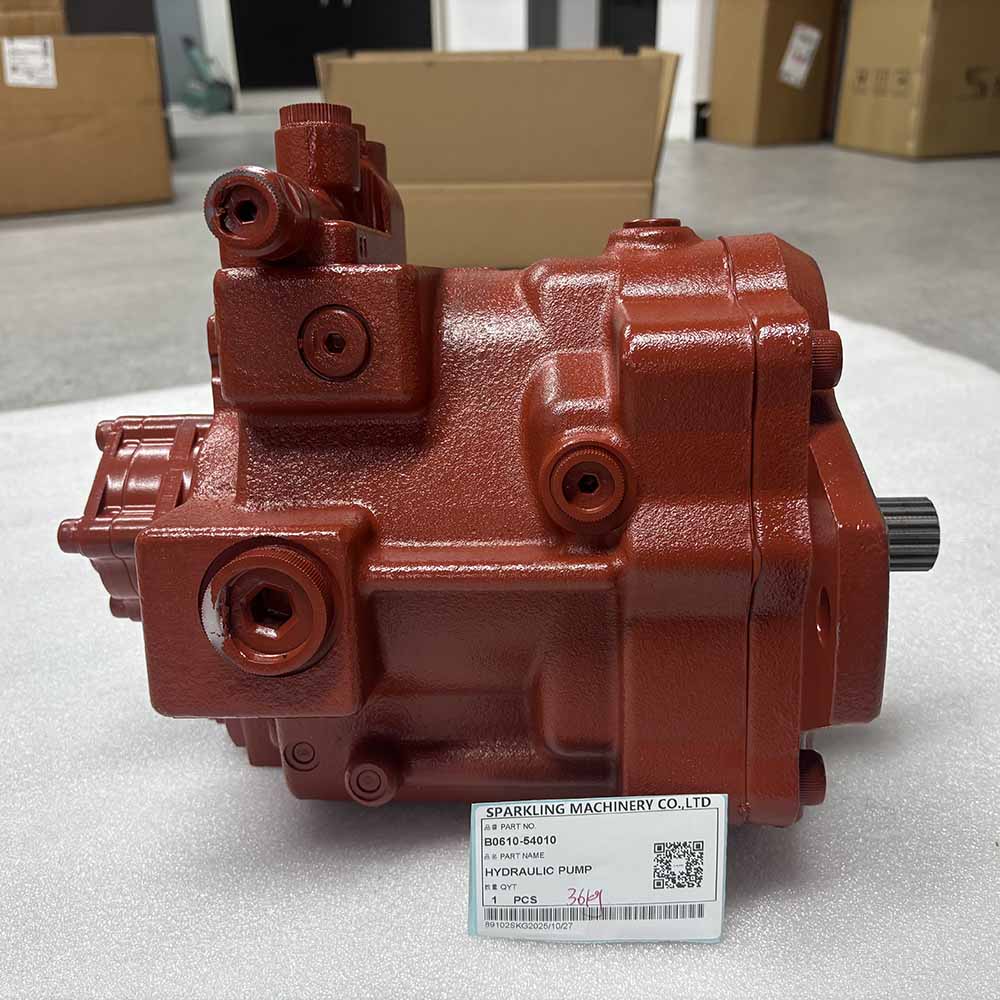

Overview of the Lingong HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B0610-54010 HYDRAULIC PUMP SPARKLING MACHINERY

SPARKLING MACHINERY NEW B0610-54010 Hydraulic Pump is a core power component for Lingong excavators (heavy-duty construction/mining use). It delivers stable high-pressure hydraulic fluid to drive critical systems like arms, booms, and travel mechanisms.

Meeting Lingong OEM standards (B0610-54010), it resists -30°C to 100°C temps, high pressure, and wear, ensuring seamless compatibility and long-term reliable hydraulic power supply.

Common failure categories for hydraulic pumps

Most hydraulic pump failures fall into clear categories: contamination, cavitation, overheating, internal wear, incorrect hydraulic fluid, mechanical misalignment, and pressure/flow anomalies. Each category has distinct symptoms and targeted fixes. Below we examine each cause in depth, list diagnostic checks, short-term fixes, and long-term preventive measures relevant to hydraulic system components on excavators.

1. Contamination: solid particles and water

Cause and symptoms: Contamination is the single largest contributor to hydraulic pump failures. Particulate contamination (dirt, metal wear particles) and water ingress cause abrasive and corrosive damage to gears, vanes, bearings, and seals. Symptoms include increasing noise, erratic flow or pressure loss, and accelerated component wear.

Diagnosis: Inspect fluid cleanliness (ISO 4406 particle count), check filters and housing for metal flakes, use a particle counter or microscope analysis, and test for water via crackle test or moisture sensors.

Short-term fixes: Replace contaminated fluid, install new filters, flush the system, and change breather caps. Remove sludge from reservoir.

Long-term prevention: Maintain a strict fluid filtration program (appropriate micron rating), install breathers and desiccant breathers, seal hydraulic system components properly, and follow scheduled sampling and particle counting. Choose components with corrosion-resistant finishes when operating in wet environments.

2. Cavitation and aeration

Cause and symptoms: Cavitation occurs when vapor bubbles form in the fluid due to local low pressure and then collapse, causing pitting and noise. Aeration (air entrainment) causes foaming, reduced lubrication, and pressure instability. Symptoms: loud knocking or gravel-like noise, reduced flow, erratic control behavior, and damage to pump surfaces.

Diagnosis: Inspect suction lines and fittings for leaks, check reservoir fluid level and return line height, and observe bubbles in the reservoir return stream. Use pressure gauges to verify suction pressure.

Fixes: Eliminate suction restrictions, ensure correct fluid levels and return tube position, tighten fittings, replace damaged hoses, and use proper suction strainers. For persistent cavitation, install accumulators or redesign suction geometry.

3. Overheating and thermal degradation

Cause and symptoms: Excessive heat reduces fluid viscosity, accelerates additive breakdown, and damages seals. Causes include overloaded systems, poor heat exchangers, blocked cooling passages, and high ambient temperatures. Symptoms include dark or burnt-smelling fluid, soft or swollen seals, loss of pressure, and shortened component life.

Diagnosis: Monitor operating temperatures, inspect fluid color and smell, and check cooler performance and flow rates. Thermography can reveal hotspots.

Fixes: Restore proper cooling (clean radiators and coolers), replace degraded fluid and seals, relieve overloads, and review hydraulic circuit design for excessive continuous loads. Use fluids rated for the operating temperature range and pumps like the NEW B0610-54010 that tolerate wide temperature spans (-30°C to 100°C).

4. Wear and internal damage (abrasive and fatigue)

Cause and symptoms: Normal wear occurs over time but accelerates with contamination, poor lubrication, and overloads. Components affected include vanes, pistons, cam rings, and bearings. Symptoms: increasing internal leakage, reduced displacement, reduced pressure capability, and metal particles in the system.

Diagnosis: Pressure and flow testing to identify internal leakage, borescope inspection where possible, and oil analysis for metal content (ferrous and non-ferrous particulate analysis).

Fixes: Repair or replace the pump cartridge or complete pump. For modular pumps, replace wear rings, pistons, or seals. Implement corrective maintenance intervals and upgrade filtration to prevent recurrence.

5. Incorrect hydraulic fluid and contamination by incompatible additives

Cause and symptoms: Using the wrong fluid or mixing incompatible fluids degrades lubricity and additive performance, causing wear, seal swelling/shrinkage, and foaming. Symptoms include seal failures, softening or hardening of elastomers, inconsistent viscosity, and early component wear.

Diagnosis: Check fluid specifications against OEM recommendations, perform viscosity measurements and elemental analysis, and inspect seals for swelling or cracking.

Fixes: Drain and flush the system, refill with OEM-recommended fluid, and replace affected seals. Implement fluid control policies to prevent contamination from top-ups with incorrect oils.

6. Mechanical alignment, mounting and shaft coupling issues

Cause and symptoms: Misalignment between pump and prime mover, loose mounting bolts, or improper coupling cause vibration, bearing overload, and shaft seal failures. Symptoms include vibration, unusual noise, and premature bearing or seal failures.

Diagnosis: Use dial indicators or laser alignment tools to check alignment, inspect couplings and mounting hardware, and check for shaft runout.

Fixes: Realign coupling and pump, torque mounting bolts to OEM specs, replace damaged couplings, and install vibration isolation mounts where required.

7. Pressure spikes and shock loads

Cause and symptoms: Sudden pressure spikes from valve slam or load reaction can overstress pump components and relief valves. Symptoms include repeated relief valve operation, hose failures, and blistered seals.

Diagnosis: Install pressure transducers to capture transient spikes, review control logic and valve sequencing, and inspect for system resonance.

Fixes: Add accumulators, pressure dampeners, or snubbers; slow valve actuation through orifice or flow-control changes; fine-tune control sequences to avoid sudden shocks.

Troubleshooting and diagnostic table for hydraulic pump failures

| Failure Mode | Key Symptoms | Likely Cause | Immediate Fix | Long-Term Prevention |

|---|---|---|---|---|

| Contamination | Noisy operation, particle in filters | Dirty reservoir, breached seals, bad filters | Fluid change & filter replacement | Filtration program; desiccant breathers |

| Cavitation | Knocking noise, pitting on components | Suction restriction, low fluid level | Check suction lines; refill fluid | Correct suction design; suction strainers |

| Overheating | Dark fluid, soft seals | Poor cooling, excessive load | Cooler cleaning, fluid change | Proper cooler sizing; thermal controls |

| Wear/Internal leakage | Loss of flow/pressure, metal particles | Normal wear; contamination | Replace worn parts | Scheduled rebuilds; filtration |

Inspection checklist for hydraulic pumps and hydraulic system components

- Daily: Visual leaks, fluid level, audible anomalies, reservoir vent condition.

- Weekly: Check filters differential pressure, hose and fitting tightness, and temperature trends.

- Monthly: Oil analysis, particle count, and quick pressure/flow checks.

- Quarterly: Inspect pump mounting, shaft coupling alignment, and clean coolers.

- Annually or per OEM hours: Full system flush, pump bench test, and rebuild if wear limits exceeded.

Why choosing the correct pump matters: advantages of the NEW B0610-54010 Hydraulic Pump

Component selection has a direct impact on system reliability. The SPARKLING MACHINERY NEW B0610-54010 is designed to meet Lingong OEM tolerances and operating conditions common in heavy construction and mining. Key advantages include robust temperature tolerance (-30°C to 100°C), materials selected for wear resistance, precise machining for tight internal clearances to reduce internal leakage, and full compatibility with standard Lingong hydraulic system components. These attributes reduce the chance of failures from wear, thermal issues, or incompatible fitment and simplify maintenance planning.

Practical maintenance program to reduce pump failures

An effective maintenance program is proactive and data-driven. Key elements are: baseline oil analysis on commissioned machines, scheduled oil sampling and particle counting, installing appropriate filtration and breathers, maintaining correct fluid levels, and training operators to recognize early symptoms. Use OEM-specified spares like NEW B0610-54010 to ensure geometry and tolerances match system requirements.

When to repair vs. replace hydraulic pumps

Minor seal and bearing issues can be repaired quickly; however, extensive scoring of internal components, high ferrous particle counts, or repeated failures often indicate a full pump replacement is more cost-effective. Bench testing provides flow vs. pressure curves to quantify internal leakage and performance loss; if the pump cannot meet OEM specifications within rebuild limits, replace it with a quality unit such as the Lingong-compatible NEW B0610-54010.

FAQ (Frequently Asked Questions)

Q1: What is the most common cause of hydraulic pump failure?

A1: Contamination (solid particles and water) is the most frequent cause. A strong filtration and fluid maintenance program prevents most of these failures.

Q2: How can I tell if my pump is cavitating?

A2: Typical signs are a gravel-like or knocking noise, reduced flow, and pitting damage. Inspect suction lines, fluid level, and for bubbles in the return stream.

Q3: How often should hydraulic fluid be analyzed?

A3: For heavy-use excavators, sample monthly for the first three months to establish baseline, then every 1–3 months depending on contamination trends and duty cycle.

Q4: Can I rebuild a worn hydraulic pump?

A4: Many pumps are rebuildable if wear is within machining limits. However, severe scoring or repeated failures may make replacement with a new OEM-spec pump the better option.

Q5: Will using a high-quality pump like NEW B0610-54010 reduce downtime?

A5: Yes. Pumps built to OEM specifications with robust materials and accurate machining reduce internal leakage, tolerate temperature extremes, and last longer under heavy duty cycles, lowering downtime risk.

Q6: What filters should I use?

A6: Select filters based on target cleanliness codes (ISO 4406). For critical excavator hydraulic system components, aim for ISO 18/16/13 or cleaner depending on the hydraulic component sensitivity.

Contact us / View product

Addressing the common causes of hydraulic pump failures is most effective when supported by a structured hydraulic system components preventive maintenance checklist that reduces wear before breakdowns occur.If you need a reliable replacement pump that matches Lingong specifications, consider the SPARKLING MACHINERY NEW B0610-54010 Hydraulic Pump. For pricing, lead times, technical drawings, or application advice, contact our sales team or view the product page. Our specialists can provide compatibility checks, maintenance recommendations, and installation support to integrate with your hydraulic system components.

Authoritative references and further reading

- Hydraulic pump basics — Wikipedia: https://en.wikipedia.org/wiki/Hydraulic_pump

- Hydraulic safety and general rules — ISO 4413: https://www.iso.org/standard/58571.

- Hydraulics basics and troubleshooting — Bosch Rexroth: https://www.boschrexroth.com

- Hydraulic system design and maintenance articles — Hydraulics & Pneumatics: https://www.hydraulicspneumatics.com

- Hydraulic component engineering and product data — Parker Hannifin: https://www.parker.com

- Manufacturer for Lingong/SDLG excavators: Shandong Lingong (SDLG): https://www.sdlg.com/

Final notes

Preventing hydraulic pump failures requires a systems approach: correct component selection, clean fluid, appropriate filtration, good thermal management, and consistent inspection. Using OEM-grade parts such as the Lingong HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B0610-54010 HYDRAULIC PUMP SPARKLING MACHINERY and following the inspection and maintenance steps above will significantly reduce downtime and extend the service life of your hydraulic system components.

The B2B Buyer’s Guide to Undercarriage Parts

The B2B Buyer’s Guide to Excavator Hydraulic Pumps | SPARKLING Ultimate Insights

Common Hub Problems and How Technicians Diagnose Them

The B2B Buyer’s Guide to Hydraulic Cylinders for Excavators

faq

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

LC10V00017F1 Main Hydraulic Pump K5V140DTP-18MR-9TBR-V for Kobelco SK330LC-6E SK330LC SK330-6 SK350-6 SK350LC

The LC10V00017F1 main hydraulic pump, model K5V140DTP-18MR-9TBR-V, is an OEM-compatible Kawasaki axial piston pump specifically engineered for Kobelco SK330LC-6E, SK330LC, SK330-6, SK350-6, and SK350LC excavators.

Key Features

· High-Pressure Performance: Advanced variable displacement design delivers max working pressure of 35 MPa (5075 psi) and displacement of 140 cm³/rev, enhancing system efficiency by 15% and reducing fuel consumption during heavy operations.

· Direct OEM Fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Efficient Flow Control: Swash plate variable displacement automatically adjusts output to match load demands, improving operational precision and minimizing heat buildup.

Compatible Models & Part Numbers

· Kobelco Excavators: SK330LC-6E, SK330LC, SK330-6, SK350-6, SK350LC

· Part Number: LC10V00017F1

· Pump Model: K5V140DTP-18MR-9TBR-V

· Interchangeable References: LC10V00017F1 (matches original Kawasaki main pump specs)

KHR13710 Heater Core for Case Construction CX160B CX220B CX290B CX470B – Cab Heating Spare Part

The KHR13710 heater core is an OEM-compatible cab heating spare part specifically designed for Case CX160B, CX220B, CX290B, and CX470B excavators.

Key Features

· Efficient heat exchange: 100% aluminum core with dense fin structure increases heat transfer area by 20%, ensuring rapid cabin warming and defrosting efficiency, even in sub-zero temperatures.

· Leak-proof design: High-integrity brazed joints and reinforced tube walls prevent coolant leakage, ensuring reliable operation and avoiding system contamination.

· Direct OEM fit: Exact replication of original mounting dimensions, pipe diameters, and interface specifications enables plug-and-play installation without modifying the heating system or dashboard components.

Compatible Models & Part Numbers

· Case Excavators: CX160B, CX220B, CX290B, CX470B

· Part Number: KHR13710

· Interchangeable References: KHR13710 (matches original heater core specs for above models)

KTJ16510 Main Hydraulic Pump for Case Excavator CX490C CX500C & Kobelco SK490 SK500

Function: It serves as the heart of the hydraulic system, providing the necessary power for digging, lifting, swinging, and traveling operations.

Key Features

· High-pressure & high-efficiency performance: Advanced axial piston design delivers a maximum working pressure of 35 MPa (5075 psi), boosting hydraulic system efficiency by 12% and reducing fuel consumption during heavy loads.

· Direct OEM fit: Exact replication of mounting flanges, shaft splines, and port configurations enables plug-and-play installation without modifying hydraulic lines or brackets.

· Optimized flow control: Variable displacement design automatically adjusts output to match load demands, enhancing operational precision and minimizing heat generation.

· Reliable sealing system: Dual-lip oil seals and reinforced O-rings prevent internal and external leaks, maintaining system pressure stability and reducing maintenance downtime.

Compatible Models & Part Numbers

· Case Excavators: CX490C, CX500C

· Kobelco Excavators: SK490, SK500

· Part Number: KTJ16510

· Interchangeable References: KTJ16510 (matches original main pump specs for above models)

K5V212DPH1J8R-9NG4-AV Hydraulic Pump - Construction Machinery Spare Parts fits EC300D EC350D EC380D R335LC-9V

The K5V212DPH1J8R-9NG4-AV is an OEM-compatible variable displacement axial piston main hydraulic pump, custom-engineered for Volvo EC300D/EC350D/EC380D and Hyundai R335LC-9V 30-38 ton excavators.

Key Features

· High-power output: 212cc displacement, max pressure 34.3 MPa, 1800 rpm rated speed—matches 150-190kW engine power for 30-38 ton excavators, ensuring efficient high-load operation.

· Precision flow control: Electro-hydraulic proportional control adjusts output per workload, cutting fuel consumption by 8% vs. standard pumps while maintaining smooth actuator response.

· Direct OEM fit: Exact mounting points, hydraulic ports, and SAE J518 flanges enable plug-and-play installation without system reconfiguration or adapter parts.

· Durable components: Hardened cylinder block, chrome-plated pistons, and wear-resistant valve plate extend service life; integrated pressure relief valve prevents overload damage.

Compatible Models & Part Numbers

· Volvo Excavators: EC300D, EC350D, EC380D

· Hyundai Excavators: R335LC-9V

· Part Number: K5V212DPH1J8R-9NG4-AV

· Interchangeable References: K5V212DPH-9N series; matches original main pump specs for above models

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879