Common Hub Problems and How Technicians Diagnose Them

- Common Hub Problems and How Technicians Diagnose Them — Excavator Parts Guide

- Product snapshot (Hyundai-compatible hub)

- Why hubs matter in excavator parts maintenance

- Common hub problems technicians encounter

- 1. Bearing noise and vibration

- 2. Grease leakage and seal failure

- 3. Overheating hubs

- 4. Excessive play / axial or radial movement

- 5. Corrosion, pitting, and impact damage

- Step-by-step diagnostic approach technicians use

- 1. Pre-inspection and safety

- 2. Visual inspection

- 3. Manual play and torque checks

- 4. Temperature measurements

- 5. Acoustic analysis

- 6. Grease sampling and contamination analysis

- 7. Dimensional checks and runout

- 8. Non-destructive testing for cracks

- Symptom-to-action quick reference table

- Tools and measurements technicians rely on

- Deciding: repair bearings vs replace the entire hub

- Maintenance practices that prevent hub failure

- Real-world diagnostic workflow example

- Why choose SPARKLING MACHINERY hubs among excavator parts options

- FAQ — Common questions about hub problems and replacements

- Q1: How long should an excavator hub last?

- Q2: Can a technician replace bearings in the field or is hub replacement usually required?

- Q3: How do I know if a SPARKLING MACHINERY hub will fit my Hyundai excavator?

- Q4: What immediate checks should I do if I detect hub noise while on site?

- Q5: Are there warranty considerations when using non-OEM hubs?

- Contact and product viewing

- References and sources

Common Hub Problems and How Technicians Diagnose Them — Excavator Parts Guide

Hubs are a critical undercarriage component on wheeled and tracked excavators: they connect the track or wheel system to the axle, bear heavy loads, and allow smooth travel. Problems in the hub quickly escalate to increased downtime and higher repair costs. This article walks technicians and fleet managers through the most common hub problems, reliable diagnostic steps, preventive maintenance, and replacement guidance — including information about the Hyundai-compatible SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub, a high-quality excavator parts option made in China designed to meet OEM standards.

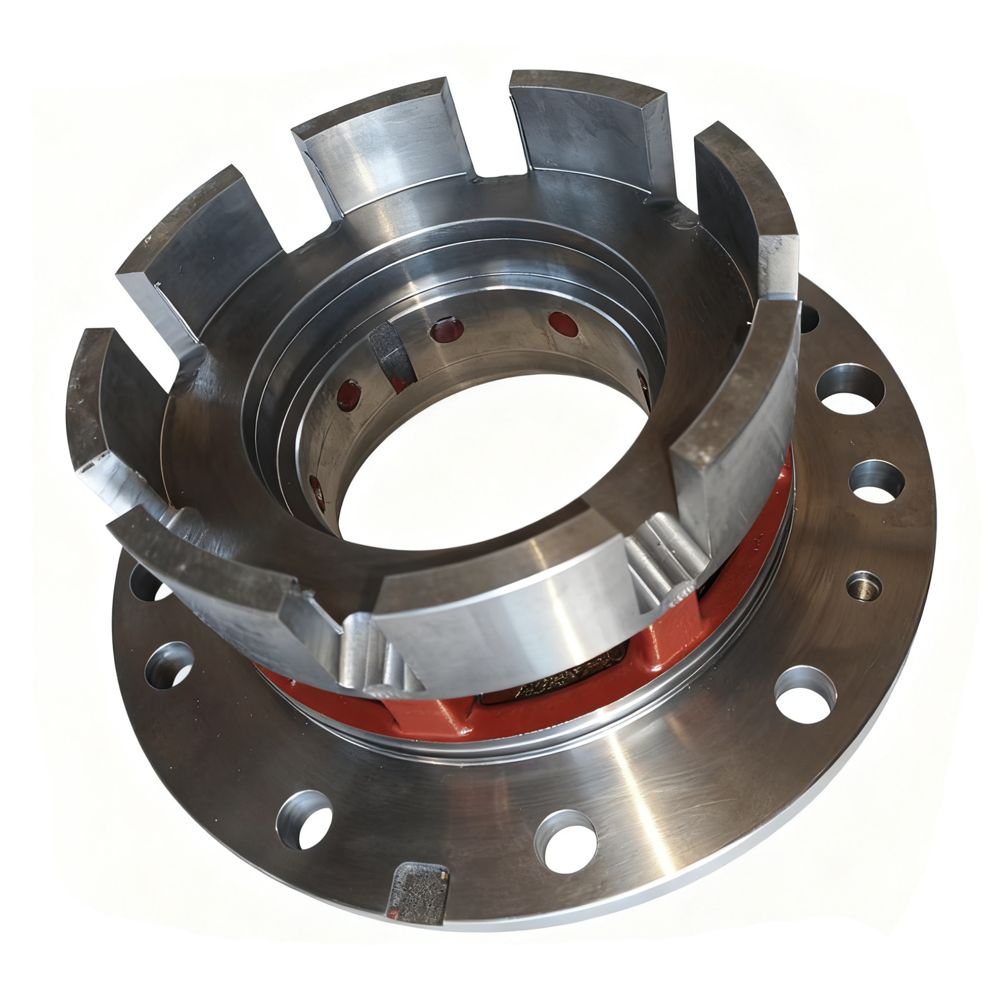

Product snapshot (Hyundai-compatible hub)

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Why hubs matter in excavator parts maintenance

Hubs transmit the machine’s weight and travel loads to the undercarriage. Failure modes include bearing wear, seal leaks, overheating, structural cracks, and misalignment. Because hubs operate under heavy cyclical loads and in abrasive environments, early detection of defects is essential to prevent collateral damage to axles, bearings, brake systems, and track components. For anyone sourcing replacement excavator parts, choosing hubs that meet OEM specifications minimizes compatibility risks and downtime.

Common hub problems technicians encounter

1. Bearing noise and vibration

Symptoms: Grinding, rumbling, or high-frequency noise during travel and under load; vibration transmitted through the axle or frame.

Common causes: Bearing fatigue, lubricant contamination, insufficient preload, or brinelling from shock loads.

2. Grease leakage and seal failure

Symptoms: Visible grease on hub exterior or undercarriage, contaminated grease, rapid lubricant depletion.

Common causes: Damaged or hardened seals, improper installation, excessive pressure from thermal expansion, or seal lip wear due to contamination.

3. Overheating hubs

Symptoms: Elevated hub temperatures after short operation, burnt-smelling grease, catastrophic bearing failure soon after heat detection.

Common causes: Bearing friction from inadequate lubrication, excessive preload, binding alignment, or internal contamination.

4. Excessive play / axial or radial movement

Symptoms: Noticeable looseness when rocking the wheel or track; side-to-side movement at the hub.

Common causes: Worn bearing raceways, depleted preloads, loose fasteners, or worn splines on mating components.

5. Corrosion, pitting, and impact damage

Symptoms: Visible pitting, rust, deformation, or cracks on hub flange or bore.

Common causes: Environmental exposure, chemical contamination, or impact from debris/obstacles.

Step-by-step diagnostic approach technicians use

Diagnosing hub problems reliably combines visual inspection, simple field tests, and instrumented checks. Follow a methodical approach to isolate the root cause and choose the most cost-effective fix.

1. Pre-inspection and safety

- Park on level ground, shut down the machine, and lock out controls.

- Support the machine with approved stands if removing wheels or lifting the undercarriage.

- Record operating history (load cycles, abnormal events, recent maintenance) — this context often indicates cause.

2. Visual inspection

Inspect seals, fasteners, hub surface, and surrounding components. Look for fresh grease paths (indicating seal failure), heat discoloration, and scoring. Visual checks can quickly identify obvious failures or components requiring deeper diagnostics.

3. Manual play and torque checks

With wheel or track stationary, gently rock the wheel/hub to detect axial or radial play. Measure torque on hub fasteners with a calibrated torque wrench. Loose or over-torqued fasteners are common contributors to leaks and premature wear.

4. Temperature measurements

Use an infrared thermometer or thermal camera to check hub temperature after brief operation (5–15 minutes). Normal operating temperatures vary by design, but hotspots (differences of 20+ °C compared to adjacent hubs) indicate friction or bearing issues.

5. Acoustic analysis

Use a mechanic’s stethoscope or electronic vibration analyzer while the hub is rotating to locate bearing rumble versus gear or gearbox noise. Directional listening helps isolate internal bearing defects.

6. Grease sampling and contamination analysis

Take a grease sample for visual inspection or lab analysis to detect water, metal particles, or abrasive solids. The presence of ferrous particles suggests bearing wear or cage damage.

7. Dimensional checks and runout

Use dial indicators to measure radial runout of the hub flange and bores. Excessive runout points to bent components or seating issues. Confirm bearing preload and clearances against OEM specifications.

8. Non-destructive testing for cracks

If fatigue cracking is suspected, perform magnetic particle inspection (MPI) or dye penetrant testing on suspect areas. Early crack detection can avoid catastrophic failure.

Symptom-to-action quick reference table

| Observed symptom | Likely root cause | Diagnostic check | Typical repair / recommended replacement |

|---|---|---|---|

| Grinding noise | Damaged bearings | Acoustic test + disassemble bearings | Replace bearings (and seals); inspect hub raceways |

| Grease leak | Broken/old seal, overpressure | Visual + rotation to locate leak path | Replace seals; clean cavity; check venting |

| Hub overheating | Insufficient lubrication or binding | IR temperature scan + grease analysis | Correct lubrication; replace damaged bearings; verify alignment |

| Excessive play | Worn raceways / loose fasteners | Dial indicator + torque checks | Replace hub assembly or bearings depending on wear |

| Visible cracks or deformation | Fatigue or impact damage | MPI / Penetrant testing | Replace hub assembly (do not repair cracked hub for high-load use) |

Table sources: OEM maintenance manuals and industry inspection guides (see sources at end).

Tools and measurements technicians rely on

- Infrared thermometer or thermal camera — quick hotspot detection.

- Mechanic’s stethoscope or vibration analyzer — locate internal bearing noise.

- Dial indicator — measure radial and axial runout and bearing endplay.

- Torque wrench — verify fastener torques to OEM specs.

- Borescope — inspect internal surfaces without full disassembly.

- Grease sampling kit / lab testing for contamination analysis.

- Magnetic particle or dye penetrant kits — crack detection.

Deciding: repair bearings vs replace the entire hub

Technicians consider three main factors: extent of damage, cost vs life expectancy, and OEM compatibility. If bearing races inside the hub are scored, pitted, or out-of-tolerance, replacing bearings alone may be inadequate because raceway defects will quickly destroy new bearings. For hubs with cracks, severe deformation, or where the bore is worn beyond machining limits, full hub replacement is required.

When choosing replacement components, using hubs that meet OEM part numbers (for example Hyundai ZGAQ-03591) avoids fit and performance issues. The SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is manufactured to match Hyundai specifications and temperature resistance (-30°C to 100°C), providing a cost-effective option among quality excavator parts.

Maintenance practices that prevent hub failure

Proactive maintenance significantly extends hub life and reduces unplanned downtime:

- Schedule grease intervals per OEM recommendations and use the correct grease grade; avoid cross-contamination.

- Inspect seals and venting regularly; replace brittle seals at first sign of damage.

- Monitor operating temperatures periodically—thermal cameras during routine checks detect early trends.

- Maintain proper track/wheel tension to avoid additional axial loads on hubs.

- Train operators to avoid high-speed travel over rough terrain and reduce sudden impacts.

- Document all inspections and repairs to build a failure-history baseline.

Real-world diagnostic workflow example

Scenario: A wheel excavator develops a humming noise and increasing travel vibration. Technician workflow:

- Record machine hours and recent events (operator reports impact the day before).

- Perform a visual inspection: find a faint grease trail at the hub seam.

- Run the machine briefly and record hub temperatures — suspect hub is 30°C hotter than opposite side.

- Use a stethoscope to pinpoint noise to inner hub area.

- Safely remove hub cover and inspect bearings — find metal flecks and raceway scoring.

- Decide to replace the whole hub assembly because raceway damage exceeds allowable repair limits; install Hyundai-compatible replacement hub that meets ZGAQ-03591 specs to restore service.

Why choose SPARKLING MACHINERY hubs among excavator parts options

When fleets require dependable replacements that balance cost and OEM fit, SPARKLING MACHINERY hubs offer several advantages:

- OEM compatibility: Manufactured to meet Hyundai part standard ZGAQ-03591 for R160W9A/R170W7/R170W7A/R170W9 models, reducing fitment and performance risks.

- Range of environmental resistance: Rated -30°C to 100°C suitable for most operating conditions without premature seal or material degradation.

- Manufacturing controls: Heat-treated steels and quality assurance processes to minimize dimensional variance and improve fatigue life.

- Cost-effectiveness: Often priced lower than OEM while meeting critical spec tolerances — a practical choice for mixed-service fleets.

- Availability: Readily available stock for common Hyundai models reduces machine downtime compared with extended OEM lead times.

FAQ — Common questions about hub problems and replacements

Q1: How long should an excavator hub last?

A1: Hub life depends on operating conditions, maintenance, and machine usage. Under regular maintenance and normal use, a hub can last several thousand hours. Heavy abrasive or impact-prone environments will shorten service life. Regular inspections and grease maintenance extend hub life.

Q2: Can a technician replace bearings in the field or is hub replacement usually required?

A2: Simple bearing replacements are feasible if raceways are in good condition. When raceways are scored, out of tolerance, or there are cracks/deformations, replacing the entire hub assembly is the safer and more durable solution.

Q3: How do I know if a SPARKLING MACHINERY hub will fit my Hyundai excavator?

A3: The SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is manufactured to Hyundai OEM standard ZGAQ-03591 and is designed specifically for those models. Verify part numbers and serial compatibility with your machine’s parts catalog before purchase.

Q4: What immediate checks should I do if I detect hub noise while on site?

A4: Stop the machine, park safely, and perform a quick visual inspection for grease leaks or obvious damage. If safe, run the machine briefly and monitor hub temperatures and noise with a stethoscope to determine severity. If the hub is hot or noise is severe, avoid further operation until addressed.

Q5: Are there warranty considerations when using non-OEM hubs?

A5: Warranty coverage varies by supplier. SPARKLING MACHINERY parts typically include supplier warranties; however, check terms and confirm compatibility to avoid voiding any machine-specific guarantees. Using certified OEM-equivalent parts often provides a good balance of warranty and cost.

Contact and product viewing

If you need replacement hubs or technical advice, contact our sales and technical team to discuss the SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub and other excavator parts. We can provide fitment confirmation, lead times, and guidance for onsite installation and torque specifications.

Contact our parts specialists now to request a quote or view product specifications. For fast service, provide your excavator model, serial number, and a short description of the issue. Finally, understanding common hub problems and how to diagnose them ties back to the need for high-quality, authentic parts. As we discussed in the R170W7A vs R170W9 comparison, knowing the key parts differences can help ensure you’re making the best choices for your machine’s needs and performance.

References and sources

- Caterpillar Maintenance & Repair Guides — Undercarriage systems overview. (Cat.com: Maintenance Library)

- Komatsu Undercarriage Components and Maintenance — Excavator maintenance bulletins. (Komatsu service manuals)

- SKF Bearing Maintenance and Failure Analysis guides — common bearing failure modes and diagnostics. (SKF.com)

- Hydraulic Excavator Operation & Maintenance Best Practices — OEM recommendations on lubrication and inspection intervals. (Various OEM technical bulletins)

Note: For specific torque values, preload settings, and wear limits consult the Hyundai OEM parts manual for models R160W9A, R170W7, R170W7A, and R170W9 or contact the machine manufacturer. For lab analysis of lubricant contamination, use ISO/ASTM accredited testing facilities.

End of article.

Best rubber track for excavator manufacturers and supplier brands

The B2B Buyer’s Guide to Hydraulic Cylinders for Excavators | SPARKLING Ultimate Insights

The B2B Buyer’s Guide to Excavator Drive Motors

The B2B Buyer’s Guide to Excavator Attachments

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879