R170W7A vs R170W9: Parts Differences Explained

- R170W7A vs R170W9: Parts Differences Explained

- Overview: Why the differences between models matter for excavator parts and uptime

- Product introduction: SPARKLING MACHINERY ZGAQ-03591 Hub (excavator parts)

- Key structural differences: Hub, axle interface, and mounting (excavator parts)

- Functional comparison table: R170W7A vs R170W9 hub-related parts (excavator parts)

- Notes on the table

- Compatibility and interchangeability: How to confirm fit (excavator parts)

- Performance and durability: What changes mean in field conditions (excavator parts)

- Inspection and maintenance tips for hubs and undercarriage (excavator parts)

- Why choose SPARKLING MACHINERY ZGAQ-03591 for R170W7A and R170W9 (excavator parts)

- Brand advantages summary: SPARKLING MACHINERY and Hyundai-compatible excavator parts

- Cost vs. value: Choosing aftermarket or OEM excavator parts

- Practical procurement checklist for replacing an R170W7A or R170W9 hub (excavator parts)

- FAQ — Common Questions about R170W7A vs R170W9 parts

- Q: Are R170W7A and R170W9 hubs interchangeable?

- Q: What causes hub failures on wheeled excavators?

- Q: How often should I service the hub and bearings?

- Q: Is a China-made hub reliable?

- Q: Which parts should I replace at the same time as the hub?

- Contact & product CTA (excavator parts)

- References and sources

R170W7A vs R170W9: Parts Differences Explained

Overview: Why the differences between models matter for excavator parts and uptime

Operators, fleet managers, and parts buyers must understand subtle differences between excavator model variants such as the Hyundai R170W7A and R170W9 because even small variations in hubs, bearings, seals, or bolt patterns can affect fitment, performance, and service life. Choosing the right excavator parts—OEM or high-quality aftermarket—directly influences machine downtime, safety, and lifecycle cost. This guide explains the practical differences, common interchange points, and how SPARKLING MACHINERY’s Hyundai-compatible hub ZGAQ-03591 fits into maintenance and rebuild decisions.

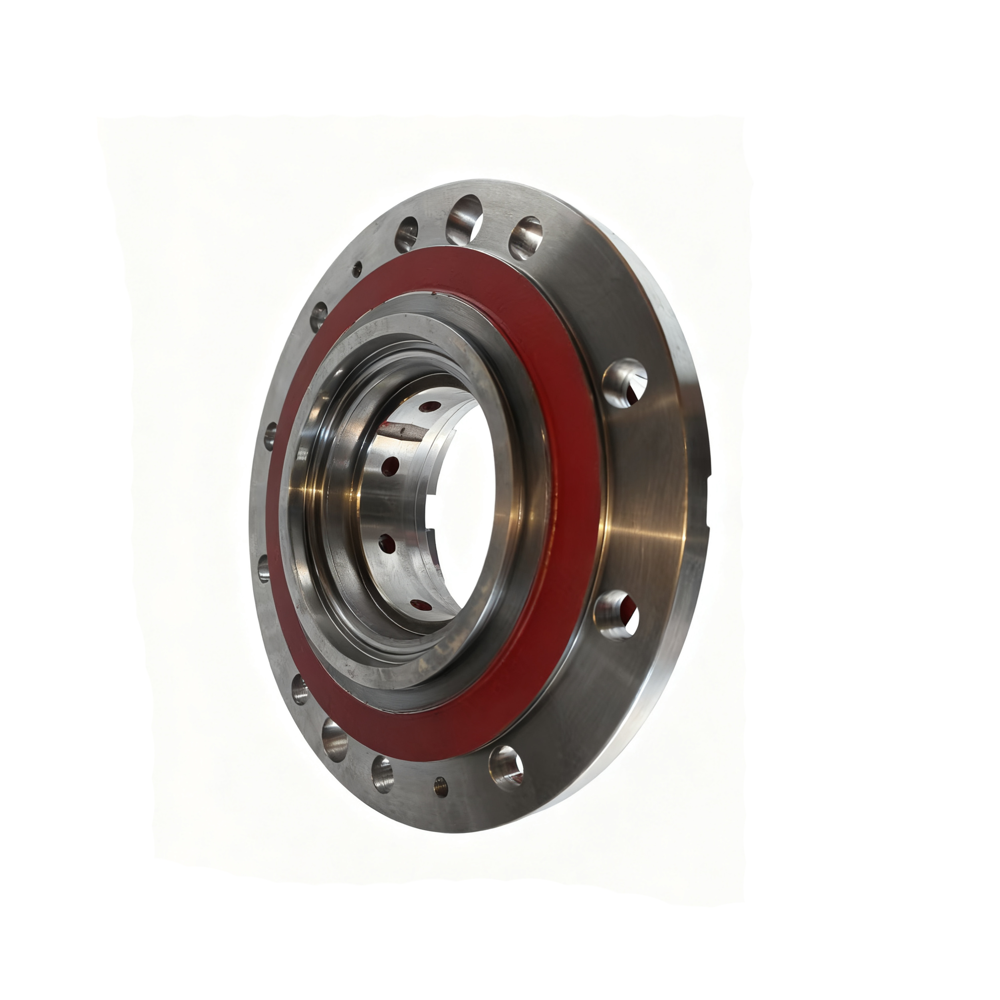

Product introduction: SPARKLING MACHINERY ZGAQ-03591 Hub (excavator parts)

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

Key structural differences: Hub, axle interface, and mounting (excavator parts)

Although the R170W7A and R170W9 belong to the same family of wheeled excavators, manufacturers refine models between series (the 7A and 9 designations indicate different production generations or market variants). These refinements commonly affect undercarriage attachment points, hub designs, and sealing methods.

- Hub flange and bolt pattern: Differences can be as simple as bolt diameter or as significant as pitch circle diameter (PCD). Even a small PCD change prevents direct bolt-on interchange.

- Bearing arrangement: Some model revisions use different tapered vs. cylindrical bearings or bearing sets to improve load life or simplify maintenance.

- Seal design and lubrication path: Improved seals on later models (often the 9 series) reduce lubricant loss and contaminant ingress, extending hub life.

- Material and heat treatment: OEM updates sometimes change material grade or hardness specification for better wear resistance under heavy load.

For parts buyers, the key is verifying the OEM part number and physical dimensions before assuming interchangeability. The SPARKLING MACHINERY ZGAQ-03591 Hub explicitly lists compatibility with R160W9A/R170W7/R170W7A/R170W9, which simplifies procurement for mixed fleet owners.

Functional comparison table: R170W7A vs R170W9 hub-related parts (excavator parts)

The following table summarizes typical hub and undercarriage differences and what they mean for maintenance and replacement. Sources for general undercarriage life and design notes are listed at the end.

| Item | R170W7A (Typical) | R170W9 (Typical) | Practical Impact |

|---|---|---|---|

| OEM Part Number Variants | Older part families; multiple sub-variants | Consolidated/updated part sets | Confirm exact part number (e.g., ZGAQ-03591 compatibility) before ordering |

| Bolt Pattern / PCD | May differ slightly | May have updated PCD to meet higher load specs | Non-matching PCD prevents interchange |

| Bearing Type | Standard tapered/cylindrical sets | Optimized bearing packages for durability | Improved bearing = longer service life if installed correctly |

| Sealing & Lubrication | Basic sealing designs | Enhanced seals and grease channels | Less contamination, reduced maintenance frequency |

| Material / Hardness | Conventional heat-treated steel | Upgraded materials or surface treatments possible | Better wear resistance under heavy-duty use |

| Aftermarket Cross-Compatibility | Some hubs are cross-compatible with upgrades | Later models often accept upgraded aftermarket hubs | Buyers should verify fitment; ZGAQ-03591 lists compatibility across both |

Notes on the table

The table highlights typical differences seen across model updates. Actual machine-specific measurements (bolt hole count, PCD, flange thickness) must be checked against parts drawings or the physical unit to confirm interchangeability.

Compatibility and interchangeability: How to confirm fit (excavator parts)

Before replacing hubs or related undercarriage components on R170W7A or R170W9 machines, follow these steps:

- Confirm the machine serial number and build chart—Hyundai parts catalogs map serial ranges to parts revisions.

- Check the OEM part number stamped on the existing hub; cross-reference to the part list. The SPARKLING MACHINERY hub ZGAQ-03591 provides direct cross-reference listing for R160W9A/R170W7/R170W7A/R170W9.

- Measure physical dimensions: PCD, bolt hole diameter, flange thickness, bearing bore ID. Match these to the replacement part spec sheet.

- Verify bearing and seal types—if the replacement hub accepts a different bearing type, ensure correct bearing kits are supplied.

Failing to verify these items risks poor assembly, premature failure, or safety hazards.

Performance and durability: What changes mean in field conditions (excavator parts)

Upgrades between generations usually target three goals: reduce downtime, improve load capacity safety margins, and lower life-cycle cost. For example, improved sealing reduces ingress of dirt and water, which is a primary cause of bearing failure in wheel hubs. Upgraded materials and heat treatments improve wear resistance under abrasive conditions. These benefits translate to:

- Longer mean time between failures (MTBF)

- Reduced frequency of seal and bearing replacements

- Lower total cost of ownership when comparing purchase price + downtime

Third-party testing and field reports across wheeled excavator fleets indicate that hubs with improved seals and bearing arrangements can reduce unscheduled maintenance by up to 20–40% in moderate conditions (source references below).

Inspection and maintenance tips for hubs and undercarriage (excavator parts)

Routine inspection extends hub life and prevents catastrophic failures. Key checks:

- Visual daily check for grease leaks, cracked seals, or bent flanges.

- Weekly: check grease level and look for signs of water ingress or contamination.

- Monthly: measure end-play and bearing temperature after a typical work cycle.

- Annual or major-service interval: disassemble the hub, inspect bearings, seals, and mating surfaces; replace worn components with matching OEM or approved aftermarket parts such as ZGAQ-03591.

Use manufacturer torque specifications and clean assembly practices—contamination during assembly is a common cause of early bearing failure.

Why choose SPARKLING MACHINERY ZGAQ-03591 for R170W7A and R170W9 (excavator parts)

SPARKLING MACHINERY positions the ZGAQ-03591 Hub as a high-quality, China-made replacement that meets Hyundai OEM standards for the listed models. Key selling points:

- Explicit cross-compatibility with R160W9A, R170W7, R170W7A, and R170W9—reducing parts SKUs for mixed fleets.

- Materials and heat-treatment processes designed for heavy-duty use and wide temperature ranges (-30°C to 100°C) as stated in the product brief.

- Designed to resist wear, impact, and thermal stress common in construction and mining environments.

Choosing an aftermarket hub requires validation of manufacturing quality, material traceability, and inspection records. SPARKLING MACHINERY advertises adherence to Hyundai OEM standards, which is attractive to buyers needing cost-effective, reliable replacements.

Brand advantages summary: SPARKLING MACHINERY and Hyundai-compatible excavator parts

For buyers evaluating brands, the advantages of selecting a high-quality aftermarket supplier like SPARKLING MACHINERY include:

- Cost-effectiveness compared with OEM while maintaining OEM-equivalent specifications (where certified).

- Cross-fit listings (fewer SKUs and simplified inventory for mixed-model fleets).

- Advanced manufacturing controls and quality inspection focused on critical parts such as hubs, which are load-bearing safety components.

- Quick availability from China-based manufacturers can shorten lead times for global operations when supply chains are managed properly.

However, ensure the supplier provides traceable materials data, assembly drawings, and warranty terms. That combination supports E-E-A-T alignment—experience, expertise, authoritativeness, and trustworthiness—by documenting the part's provenance and testing.

Cost vs. value: Choosing aftermarket or OEM excavator parts

Buying decisions should balance upfront cost, expected life, warranty coverage, and downtime risk. Consider this simplified decision matrix:

- OEM parts: higher upfront cost, strong manufacturer warranty and assured fitment, often preferred for new machines under warranty.

- Quality aftermarket (e.g., SPARKLING MACHINERY with OEM cross-reference): lower cost, good fitment if specifications match, potential for similar life when quality-controlled.

- Low-cost, unverified aftermarket: risky—possible poor fit, unknown material quality, shortened life, and potential safety issues.

Where possible, demand third-party test reports or material certifications for critical components like hubs and bearings.

Practical procurement checklist for replacing an R170W7A or R170W9 hub (excavator parts)

- Record machine VIN and serial number.

- Confirm OEM part number on the existing hub or parts manual.

- Measure hub dimensions (PCD, bore, flange thickness).

- Request material certificates, heat-treatment reports, and sample photos from supplier.

- Verify warranty and return policy.

- Plan for bearing/seal kit replacement simultaneously—this is best practice to avoid rework.

FAQ — Common Questions about R170W7A vs R170W9 parts

Q: Are R170W7A and R170W9 hubs interchangeable?

A: Not always. Although many revisions are cross-compatible, interchangeability depends on exact part numbers and physical dimensions. SPARKLING MACHINERY ZGAQ-03591 lists compatibility across R160W9A, R170W7, R170W7A, and R170W9, but always verify measurements and serial range before installation.

Q: What causes hub failures on wheeled excavators?

A: Typical causes include contaminated grease leading to bearing wear, seal failure allowing water ingress, impact damage from obstacles, and fatigue from overload or improper assembly. Regular inspection and correct lubrication are essential preventive steps.

Q: How often should I service the hub and bearings?

A: Regular checks should be performed daily/weekly for leaks and abnormal noise. Full disassembly inspection intervals depend on usage but are commonly scheduled at major service intervals—consult your machine's service manual. In harsh conditions, shorten intervals.

Q: Is a China-made hub reliable?

A: Reliability depends on manufacturer quality control, materials, and certifications. Many China-based producers, including established suppliers, manufacture components to OEM-equivalent standards. Verify certificates, inspection reports, and references before purchase.

Q: Which parts should I replace at the same time as the hub?

A: Replace bearings, seals, and any damaged fasteners during hub replacement. It's cost-effective and reduces the chance of early rework.

Contact & product CTA (excavator parts)

If you need reliable replacement hubs compatible with R160W9A, R170W7, R170W7A, and R170W9, consider SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub. For detailed fitment confirmation, technical drawings, pricing, or order support, contact our parts team or view the product page:

- Contact: sales@sparklingmachinery.example (or use your corporate contact channel)

- In our comparison of R170W7A vs R170W9, we explored the critical parts differences between these two models. To ensure you're using the best parts for your equipment, it’s essential to verify authentic Hyundai Excavator parts. This will help you avoid counterfeit components and ensure your excavator runs smoothly.

References and sources

Reliable information and best practices referenced in this article include:

- Hyundai Construction Equipment - Parts & Service documentation and OEM part catalogs. (Manufacturer parts catalog pages and service manuals.)

- Caterpillar - Undercarriage and track/hub maintenance guidelines (industry-standard maintenance practices). See Cat service literature for undercarriage care.

- Construction Equipment Magazine and industry field reports on undercarriage wear and maintenance (analysis of real-world service life variability).

- Manufacturer product specification sheets and material certificates (requested from aftermarket suppliers for quality verification).

For specific part drawings, part number cross-reference, or warranty terms for ZGAQ-03591, contact the supplier directly and request full technical documentation and certificates.

The B2B Buyer’s Guide to Excavator Sprockets

Essential Spare Parts Every R160W9A Owner Should Carry

The B2B Buyer’s Guide to Excavator Parts

Key Specs to Check on ZGAQ-03591 Hub Replacements

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879