Key Specs to Check on ZGAQ-03591 Hub Replacements

- Key Specs to Check on ZGAQ-03591 Hub Replacements

- Introduction — why the ZGAQ-03591 hub matters for excavator parts

- Product overview: SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

- 1. Compatibility and Fitment (Primary check for excavator parts)

- 2. Material Specification and Heat Treatment

- 3. Wear Resistance, Coating and Corrosion Protection

- 4. Bearings, Seals and Lubrication Interfaces

- 5. Load Rating and Fatigue Life

- 6. Thermal Performance (–30°C to 100°C check)

- 7. Dimensional Tolerances and Quality Control

- 8. Testing and Certification

- 9. OEM vs Aftermarket Considerations for excavator parts

- 10. Installation and Torque Procedures

- 11. Inspection Checklist Before Commissioning

- 12. Maintenance Best Practices to Maximize Life of ZGAQ-03591 Hub

- 13. Cost vs Lifecycle: Total Cost of Ownership for excavator parts

- 14. Supplier Validation: Questions to Ask Your Hub Vendor

- 15. Quick Dimension and Spec Comparison (OEM vs SPARKLING MACHINERY)

- 16. Field Signs of Hub Wear and Imminent Failure

- 17. Brand Advantages — Why consider SPARKLING MACHINERY for excavator parts

- FAQ — Common Questions About ZGAQ-03591 Hub Replacements

- Q1: Can I use any hub labeled ZGAQ-03591?

- Q2: Should I buy the hub with bearings and seals pre-installed?

- Q3: What lubricant should I use after installing a replacement hub?

- Q4: How do I validate the supplier's claims?

- Q5: What is the typical warranty for a hub replacement?

- Contact / View Product CTA

- Sources and References

Key Specs to Check on ZGAQ-03591 Hub Replacements

Introduction — why the ZGAQ-03591 hub matters for excavator parts

The hub that connects an excavator track to its axle is a safety- and uptime-critical component. For Hyundai wheeled excavators like R160W9A, R170W7, R170W7A and R170W9, the ZGAQ-03591 hub transfers loads, resists impacts and wear, and helps maintain track alignment. Choosing the right replacement affects machine reliability, operating cost and site safety. This article focuses on what technicians, buyers and fleet managers must check before installing a replacement hub — especially when evaluating SPARKLING MACHINERY replacements in the competitive market for excavator parts.

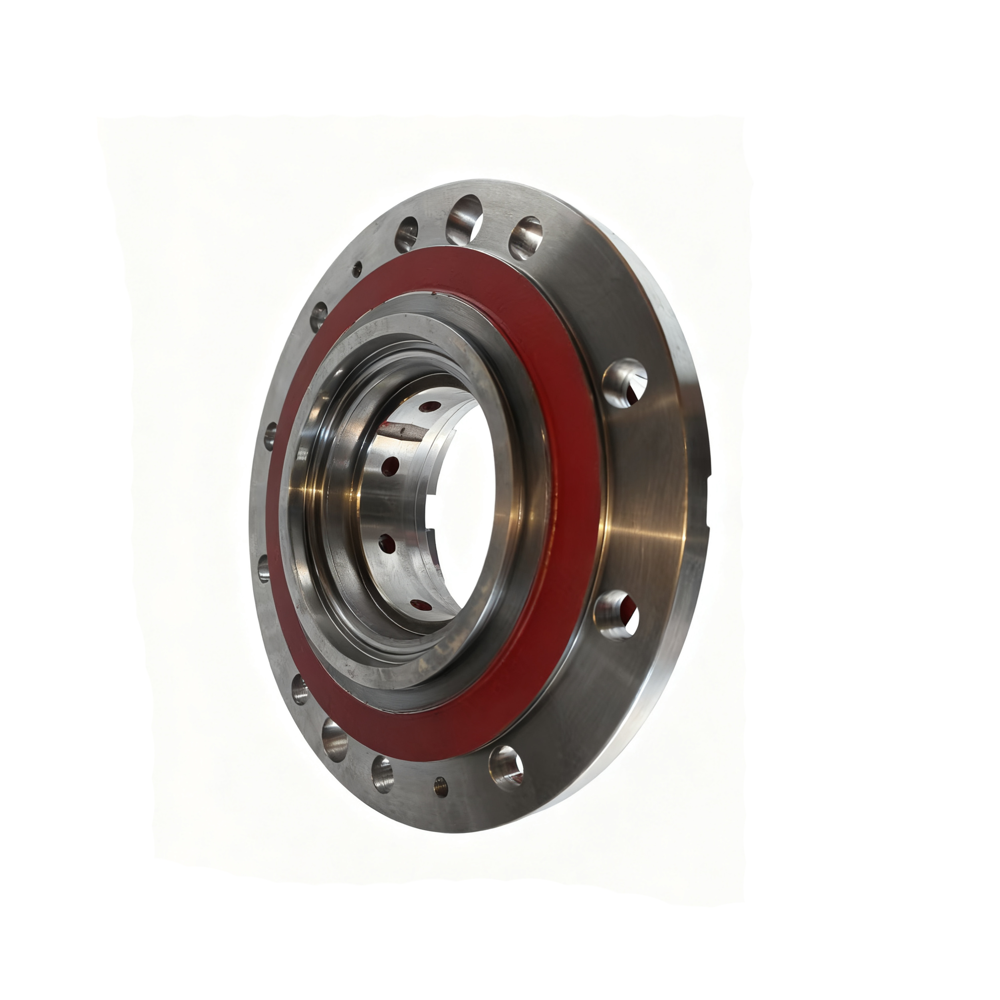

Product overview: SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

1. Compatibility and Fitment (Primary check for excavator parts)

First confirm mechanical compatibility. A correct ZGAQ-03591 replacement must match bolt pattern, center bore, spline dimensions (if applicable), flange orientation, and overall external dimensions so it seats correctly without preload issues. Mismatched geometry causes uneven load, accelerated wear, and potential failure of adjacent parts (bearings, seals, track links).

- Verify exact Hyundai model fit: R160W9A / R170W7 / R170W7A / R170W9.

- Check part number equivalence: ZGAQ-03591 (confirm vendor lists this as direct replacement).

- Use calipers/telescoping gauges to confirm critical dimensions from the old hub against the replacement before installation.

2. Material Specification and Heat Treatment

Material and heat treatment determine fatigue, impact resistance and wear life. Most high-quality hubs are made from alloy steel with controlled chemistry and are quench-and-tempered to achieve a target hardness and toughness balance. Ask for the material grade, tensile properties and heat treatment report.

Key checks:

- Material grade (e.g., alloy steel type or casting grade) and certificate of conformity.

- Hardness range (Brinell or HRC) and hardness map if available.

- Heat treatment process (quench & temper, normalized, stress-relieving) and CTQ reports.

3. Wear Resistance, Coating and Corrosion Protection

Undercarriage hubs operate in abrasive, wet, and corrosive environments. Surface treatments (nitriding, induction hardening, shot peening) and corrosion protection (zinc plating, phosphate + paint) extend service life. Confirm the replacement meets or exceeds Hyundai's surface treatment specifications.

4. Bearings, Seals and Lubrication Interfaces

Often replacement hubs are supplied with or without bearings/seals. Verify the seal design, bearing tolerances, lubrication grooves and grease ports. A poor sealing solution will allow ingress of dirt and water, dramatically shortening service life.

- Check bearing internal clearance and match with axle tolerances.

- Inspect seal lip material and spring design (expected to resist contaminants and maintain grease retention).

- Confirm grease specification and relubrication intervals recommended by vendor.

5. Load Rating and Fatigue Life

Hubs must support dynamic and static loads under typical operating cycles. Reliable suppliers provide load-rating data, fatigue life estimates and, ideally, finite-element analysis (FEA) validation. When supplier data is missing, evaluate life through material/hardness and geometry comparisons to OEM hubs.

6. Thermal Performance (–30°C to 100°C check)

SPARKLING MACHINERY states resistance from -30°C to 100°C. Confirm that seals, lubricants, and materials retain properties across this range. Low-temperature brittleness and high-temperature softening are both failure risks.

7. Dimensional Tolerances and Quality Control

Ask suppliers for dimensional inspection reports, PPAP-like documentation or QC checklists. Key tolerance areas include bolt hole position, flange flatness, concentricity of bores and spline tolerances. These dimensions directly affect bearing preload and track alignment.

8. Testing and Certification

High-quality hubs go through testing: dimensional inspection, hardness mapping, non-destructive testing (NDT) such as magnetic particle or ultrasonic for internal flaws, salt spray for corrosion resistance, and dynamic load testing. Request test reports and traceable batch numbers to make sure each delivered hub meets expectations.

9. OEM vs Aftermarket Considerations for excavator parts

OEM parts provide known quality and fit; aftermarket hubs (like those from SPARKLING MACHINERY) can offer cost savings but require careful vetting. Evaluate on:

- Documented specifications and test reports.

- Traceability (material certificates, heat-treatment records).

- Warranty and support (return, replacement, technical assistance).

- References or field performance data from fleets using the part.

10. Installation and Torque Procedures

Correct installation procedures matter as much as component quality. Ensure technicians follow Hyundai torque specs, preloading sequence, and alignment checks. Mis-torqued bolts or uneven flange contact often cause premature bearing failure or hub cracking.

11. Inspection Checklist Before Commissioning

Before putting a new hub into service, perform these checks:

- Visual inspection for casting/forging defects and machining marks.

- Dimensional verification of bolt circle and bore runout.

- Hardness spot checks and surface finish inspection.

- Seal fit and grease path verification.

- Confirm part number and batch traceability.

12. Maintenance Best Practices to Maximize Life of ZGAQ-03591 Hub

Routine maintenance extends hub life: regular greasing with the correct lubricant, seal inspection at service intervals, and track tension checks to prevent overloading. Keep an inspection log with serial numbers and installation dates to analyze wear trends across your fleet.

13. Cost vs Lifecycle: Total Cost of Ownership for excavator parts

Do not compare only purchase price. Consider expected life, downtime cost, ease of replacement, and warranty coverage. A higher initial cost may be justified by longer intervals between replacements and lower downtime — especially on high-utilization machines.

14. Supplier Validation: Questions to Ask Your Hub Vendor

When evaluating SPARKLING MACHINERY or other suppliers, request:

- Material certificates and heat-treatment reports.

- Batch-specific dimensional QC reports and NDT results.

- Service or performance data from other customers/fleets.

- Warranty terms, including replacement and failure analysis process.

- Traceability for raw materials and manufacturing dates.

15. Quick Dimension and Spec Comparison (OEM vs SPARKLING MACHINERY)

The following table is a condensed comparison to illustrate the types of spec checks you should request and compare. Values should be verified with vendor documentation before purchase.

| Spec / Check | Hyundai OEM (typical target) | SPARKLING MACHINERY (as advertised) |

|---|---|---|

| Fitment / Models | R160W9A / R170W7 / R170W7A / R170W9 | R160W9A / R170W7 / R170W7A / R170W9 (ZGAQ-03591) |

| Operating Temp | Typically -30°C to 100°C | -30°C to 100°C (advertised) |

| Material | Alloy steel (controlled chemistry, OEM spec) | Alloy steel with heat treatment (vendor cert required) |

| Corrosion Protection | OEM coating / paint per spec | Surface treatment & corrosion-resistant coatings (advertised) |

| Testing | Dimensional, hardness, NDT (OEM QC) | Supplier claims: passes dimensional & hardness; request reports |

| Warranty | OEM warranty (varies by dealer) | Supplier warranty (confirm length and terms) |

Note: Table data are representative. Always request batch-specific documentation from the supplier. For example, SPARKLING MACHINERY advertises OEM-standard build for ZGAQ-03591 hubs; verify with their test certificates.

16. Field Signs of Hub Wear and Imminent Failure

Watch for these signs during operation or inspection:

- Unusual vibration or clunking from the track area.

- Rapid grease contamination (metallic particles in grease).

- Visible cracks, gouging or spalling on flange faces.

- Excessive heat build-up during operation.

17. Brand Advantages — Why consider SPARKLING MACHINERY for excavator parts

When evaluating SPARKLING MACHINERY ZGAQ-03591 hubs, consider these strengths commonly cited by professional buyers:

- Direct-fit replacements built to match OEM geometry for Hyundai R160W9A and R170W-series machines, reducing fitment risk.

- Advertised thermal range and impact resistance suitable for heavy-duty construction use.

- Cost-effective alternatives with QC processes — ideal for fleets balancing budget and downtime.

- Availability of batch test reports and traceability on request (always confirm before purchase).

SPARKLING MACHINERY combines manufacturing capacity in China with aftermarket focus, offering competitive pricing and the ability to provide OEM-equivalent features. For critical components like hubs, however, buyer diligence (certificates, test reports, and warranty clarity) is essential.

FAQ — Common Questions About ZGAQ-03591 Hub Replacements

Q1: Can I use any hub labeled ZGAQ-03591?

A1: No. Confirm that the vendor supplies the correct fitment for the exact Hyundai model (R160W9A / R170W7 / R170W7A / R170W9) and provides dimensional and material documentation. Some aftermarket parts use the same number but differ in tolerances or material quality.

Q2: Should I buy the hub with bearings and seals pre-installed?

A2: Pre-installed bearings and seals save assembly time and reduce contamination risk if installed in a clean environment. However, ensure the supplier uses correct bearing brands/types and provides grease specs. If uncertain, install bearings/seals from a trusted source after checking tolerances.

Q3: What lubricant should I use after installing a replacement hub?

A3: Follow Hyundai recommended grease type and relubrication intervals. If using aftermarket parts, confirm the supplier’s grease recommendation — do not mix incompatible greases.

Q4: How do I validate the supplier's claims?

A4: Request material certificates, hardness maps, NDT reports, dimensional inspection reports and serial/batch traceability. Field references from other fleets and formal warranty terms are also strong validation tools.

Q5: What is the typical warranty for a hub replacement?

A5: Warranties vary. OEM dealers typically offer limited warranties; aftermarket suppliers offer their own terms. Confirm what failure modes are covered (manufacturing defects vs wear) and required evidence for claims.

Contact / View Product CTA

When considering hub replacements for your Hyundai excavator, it's crucial to know the key specs to check on ZGAQ-03591 hub replacements. This ensures you select the right parts. For long-term durability, you'll also want to focus on evaluating material quality in excavator hubs to guarantee that you are getting the best possible parts for your equipment.If you would like to review product specifications, request batch test reports, or place an order for the Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY, contact our sales team. Provide your machine model, serial number and whether you require hubs with pre-installed bearings/seals for a faster quotation and validation package. Contact: sales@sparkling-machinery.example (or call your regional parts representative).

Sources and References

Reliable reference sources and industry standards used to prepare this guide:

- Hyundai Construction Equipment official parts and service documentation (Hyundai Construction Equipment Co., Ltd.)

- SAE International publications on gear, bearing and structural materials (SAE.org)

- ISO standards for mechanical testing and corrosion testing (e.g., ISO 9227 for salt spray)

- ASTM standards for material and casting specifications (ASTM International)

- Industry best-practice service manuals from major OEMs (e.g., Caterpillar, Komatsu) for maintenance procedures and torque specifications

Note: For purchase decisions, always request supplier-specific certificates and batch reports. The table and specification comparisons above are illustrative; confirm exact values with the vendor and Hyundai technical documentation.

Wholesale heavy machinery control column manufacturer and supplier

Hydraulic System Components: Preventive Maintenance Checklist

Best Practices for Installing an Excavator Hub

The B2B Buyer’s Guide to Hydraulic Cylinders for Excavators | SPARKLING Ultimate Insights

faq

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

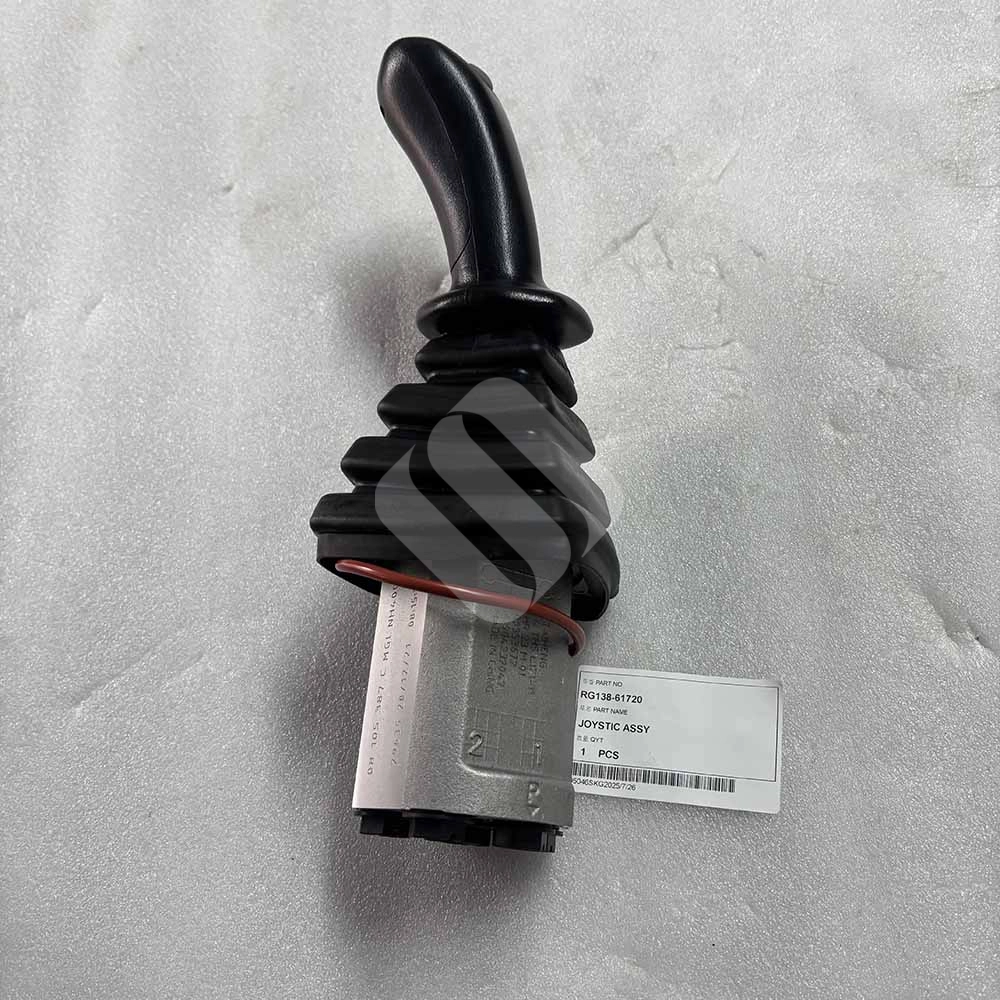

KUBOTA MADE IN CHINA SPARKLING MACHINERY NEW KX016 KX018 RG138-61720 JOYSTICK ASSY

SPARKLING MACHINERY NEW KX016 KX018 RG138-61720 Joystick Assy is a dedicated operational control component exclusively designed for KX016 and KX018 mini excavators—ideal for small-scale construction, landscaping, and indoor renovation tasks. As the core of the excavators’ human-machine interface, it enables precise control of the machine’s working mechanisms (e.g., bucket movement, arm lifting, and body rotation) by translating the operator’s manual inputs into electrical or hydraulic signals. This function is critical for ensuring smooth, accurate operation during delicate tasks like trench digging, material placement, and narrow-space maneuvering, directly enhancing work efficiency and reducing the risk of operational errors that could damage the machine or surrounding structures.

Engineered to match original equipment performance standards, it maintains responsive control and structural durability even under harsh working conditions, including continuous operator use, vibration, and exposure to dust or light moisture. It resists switch failure and handle loosening, avoiding control delays or malfunctions that lead to unplanned downtime. Backed by strict performance verification, it guarantees reliable operational control to support uninterrupted use of KX016/KX018 mini excavators.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Caterpillar HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 336 330 515-6165 FLY WHEEL SPARKLING MACHINERY

SPARKLING MACHINERY NEW 336 330 515-6165 Fly Wheel is a core powertrain component for Caterpillar 336/330 excavators (heavy-duty construction/mining use). It stores rotational energy, ensures smooth engine operation, and transmits torque to the transmission system.

Meeting Caterpillar OEM standards (515-6165), it resists -30°C to 100°C temps, mechanical stress, and wear, ensuring seamless compatibility and long-term reliable energy transfer performance.

Doosan HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW 229-00012A COVER SPARKLING MACHINERY

SPARKLING MACHINERY NEW 229-00012A Cover is a core protective component for Doosan excavators (heavy-duty construction/mining use). It shields critical internal parts (e.g., engine accessories, hydraulic components) from dust, debris, and external impact, maintaining system integrity.

Meeting Doosan OEM standards (229-00012A), it resists -30°C to 100°C temps, corrosion, and mechanical wear, ensuring seamless compatibility and long-term reliable protection for Doosan excavator systems.

Sparkling Machinery Co.,Ltd

foreverlucia1