How to Verify Authentic Hyundai Excavator Parts

- How to Verify Authentic Hyundai Excavator Parts: Practical Steps for Buyers

- Why verifying excavator parts matters for uptime, safety, and cost

- Understand part numbers, OEM codes, and documentation (excavator parts)

- Visual and packaging inspection (excavator parts)

- Technical verification: dimensions, weight, metallurgy, and coatings (Hyundai excavator parts)

- Authentication technologies: serial numbers, QR codes, holograms, and traceability (excavator parts)

- Use authorized channels and supplier due diligence (excavator parts)

- Practical verification checklist you can use onsite (excavator parts)

- Testing and fitment validation (Hyundai HIGH-QUALITY EXCAVATOR PARTS)

- Product spotlight: SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

- Comparison: Genuine OEM vs High-quality aftermarket vs Counterfeit (excavator parts)

- How to purchase with confidence: supplier checklist (excavator parts)

- Brand advantages: Why consider SPARKLING MACHINERY for Hyundai excavator parts

- FAQ — Common questions about verifying Hyundai excavator parts

- Q: How can I tell if a part marked ZGAQ-03591 is genuine?

- Q: Are high-quality aftermarket parts safe to use instead of Hyundai genuine parts?

- Q: What immediate red flags indicate counterfeit excavator parts?

- Q: Should I refuse installation if my part fails verification?

- Q: Can I verify authenticity after installation?

- Contact us / View Product — get verified parts now

- References

How to Verify Authentic Hyundai Excavator Parts: Practical Steps for Buyers

Why verifying excavator parts matters for uptime, safety, and cost

When you run heavy machinery, every component matters. Counterfeit, remanufactured without documentation, or simply incorrect excavator parts can cause premature wear, downtime, safety incidents, and higher lifecycle costs. Buying verified authentic parts — or OEM-equivalent, high-quality replacements — protects machine performance, maintains warranty coverage, and ensures operator safety. This guide explains reliable, actionable methods you can use today to verify authentic Hyundai excavator parts, including the Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 HUB SPARKLING MACHINERY example. Once you've learned how to verify the authenticity of Hyundai parts, you may be curious about Made-in-China excavator parts. While these can be a cost-effective alternative, it’s important to know the quality standards to check to ensure you're getting parts that meet the required durability and performance standards.

Understand part numbers, OEM codes, and documentation (excavator parts)

Every Hyundai genuine component carries a specific OEM part number and usually an associated catalog entry. For example, the hub used on Hyundai R160W9A/R170W7 series is identified as ZGAQ-03591 in Hyundai's parts structure. The first and most reliable verification step is cross-referencing the part number against Hyundai's official parts catalog or an authorized dealer’s database.

- Check that the part number (e.g., ZGAQ-03591) is stamped, laser-etched, or printed on the part and matches the catalog entry for your model (R160W9A, R170W7, R170W7A, R170W9).

- Request a copy or screenshot of the parts catalog entry from the seller — genuine suppliers can provide clear documentation showing compatibility, illustrations, and OEM references.

- Beware of similar or near-matching numbers; counterfeiters often use numbers that differ by a single digit or letter.

Visual and packaging inspection (excavator parts)

Visual cues are quick and effective. Examine packaging, labels, and the part itself for inconsistencies that often reveal counterfeit or low-quality parts.

- Packaging: Genuine parts typically ship in branded Hyundai packaging or in factory-sealed boxes with consistent fonts, logos, and holograms (if applicable). Poor print quality, misspellings, or generic packaging are red flags.

- Labeling: Look for QR codes, barcodes, and clear OEM part numbers. Scan QR codes to verify they redirect to official resources (or supplier verification pages).

- Markings on the part: Stamps or labels should be crisp, evenly applied, and positioned as in OEM photos. Smudged or uneven markings can indicate aftermarket casting or relabeling.

Technical verification: dimensions, weight, metallurgy, and coatings (Hyundai excavator parts)

Counterfeit parts often fail to match critical technical specifications. A simple set of checks with basic tools can detect many fakes before installation.

- Dimensions and tolerances: Measure bolt hole spacing, bore diameters, flange thickness, and overall dimensions. Compare against OEM drawings or parts catalog tolerances.

- Weight: A genuine hub will have a predictable mass based on casting density and machining. Significant differences often indicate a different alloy or lower casting quality.

- Material and hardness: If possible, request a material certificate (MTC) or hardness test results. Genuine or high-quality replacement parts use specified materials (e.g., forged or heat-treated steel) with documented metallurgical properties.

- Surface treatment: OEM hubs typically have controlled surface finishes, coatings, or heat treatments for wear resistance and corrosion protection. Poor coating adhesion, flaking, or obvious rust on a “new” part is a red flag.

Authentication technologies: serial numbers, QR codes, holograms, and traceability (excavator parts)

Modern manufacturers and reputable suppliers increasingly embed traceability features into parts and packaging. Use these features to validate authenticity.

- Serial numbers: Confirm serial numbers with the manufacturer or authorized dealer system. A valid serial number should resolve in Hyundai’s or the authorized distributor’s database.

- QR codes and barcodes: Scan codes using your phone or a reader. Authentic codes should link to parts information pages or supplier verification portals, not to generic or unrelated sites.

- Holograms and security labels: Many OEMs and reputable suppliers use tamper-evident seals or holographic stickers. These can be hard to replicate convincingly.

- Blockchain/traceability platforms: Some suppliers provide batch tracking or blockchain-backed provenance. Where available, request or scan the provenance record for the batch.

Use authorized channels and supplier due diligence (excavator parts)

Where you buy matters as much as what you buy. Purchasing through verified channels dramatically reduces the risk of counterfeit parts.

- Authorized Hyundai dealers: Always the safest route for OEM genuine parts. Dealers provide documentation, warranty, and traceability.

- Reputable distributors: If using distributors, verify their status with Hyundai or check for distributor certifications, positive reviews, and established industry references.

- Supplier audit: Ask for factory audits, ISO 9001 certification, production photos, and third-party test reports when buying aftermarket high-quality replacements.

- Payment and shipping: Unusual payment requests (wire to personal accounts) or shipping from residential addresses are warning signs.

Practical verification checklist you can use onsite (excavator parts)

Before installation, use this quick checklist:

- Confirm OEM part number (e.g., ZGAQ-03591) on part and paperwork.

- Measure critical dimensions and compare to OEM specs.

- Scan QR code/serial and validate with manufacturer/distributor.

- Inspect packaging and markings for consistency.

- Request material certificate or hardness test if high risk.

- Record images and serials and store purchase invoice/warranty.

Testing and fitment validation (Hyundai HIGH-QUALITY EXCAVATOR PARTS)

Even after visual and documentation checks, practical fitment and function testing are essential. Conduct these steps in a controlled way.

- Dry fit: Assemble the hub to the axle and track system without load to check alignment, bolt engagement, and free rotation.

- Torque verification: Use calibrated torque wrenches and Hyundai-recommended torque values during installation.

- Operational test: Run the machine at low load and inspect for abnormal vibrations, noises, or temperature rises.

- Wear monitoring: After initial hours of operation (as recommended by OEM), inspect for early wear patterns. Rapid or uneven wear indicates poor material or machining quality.

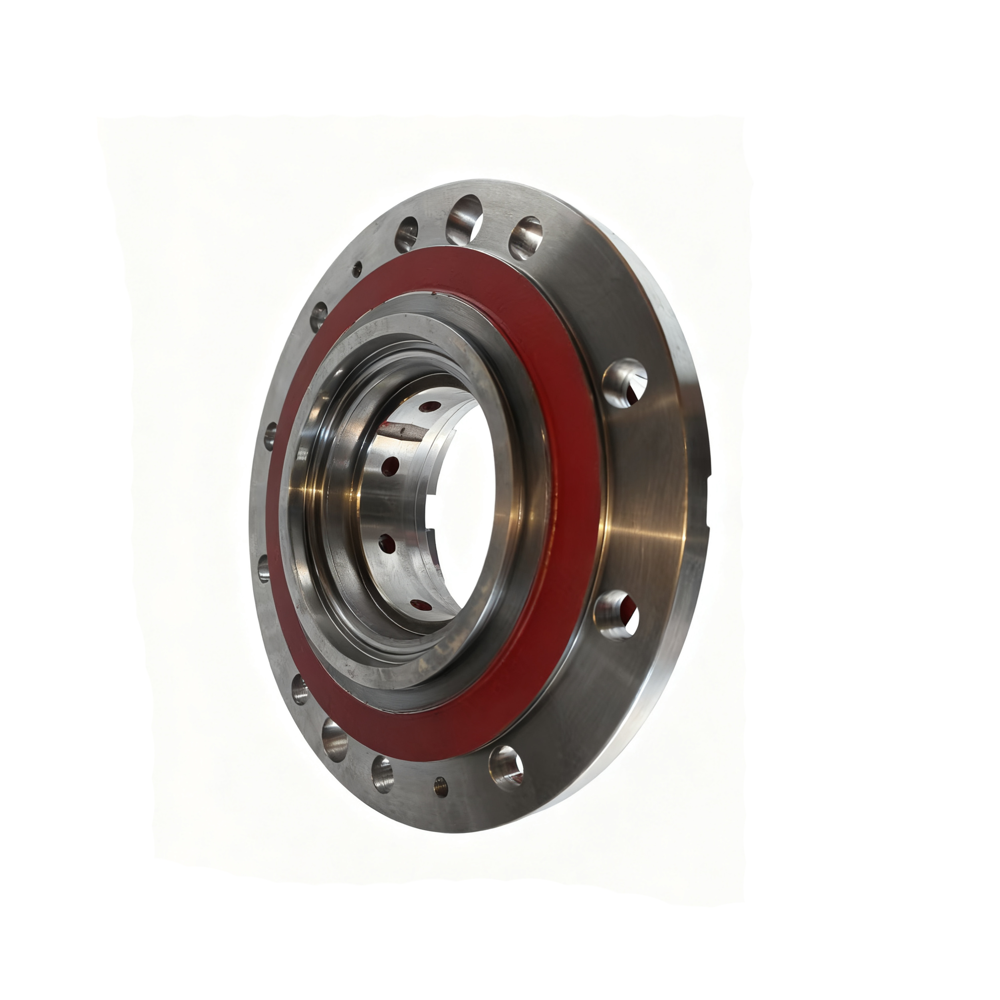

Product spotlight: SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub

SPARKLING MACHINERY NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub is a core undercarriage component for Hyundai R160W9A/R170W7/R170W7A/R170W9 excavators (heavy-duty construction/mining use). It connects the excavator’s track system to the axle, supporting load and ensuring stable travel.

Meeting Hyundai OEM standards (ZGAQ-03591), it resists -30°C to 100°C temps, wear, and impact, ensuring seamless compatibility and long-term reliable load-bearing performance.

This hub is presented by SPARKLING MACHINERY as a high-quality OEM-equivalent part produced in China, intended to meet Hyundai OEM dimensions and performance. When verifying parts like this hub, use the steps above: confirm the ZGAQ-03591 number, request MTCs or quality certificates, and perform dimensional and fitment checks before extended operation.

Comparison: Genuine OEM vs High-quality aftermarket vs Counterfeit (excavator parts)

Below is a practical comparison table to help you judge a part at a glance. Values reflect typical expectations and are shown for guidance.

| Attribute | Genuine Hyundai OEM | High-quality aftermarket (documented) | Counterfeit / Low-quality |

|---|---|---|---|

| Part number & traceability | Official Hyundai number, dealer traceable | Uses OEM number or documented equivalent; traceable batch data | Incorrect/altered numbers, little/no traceability |

| Material certs & testing | Full MTCs and factory QC records | MTCs or third-party tests often available | No certs or fabricated documents |

| Fit & tolerances | OEM tolerances guaranteed | Generally within tolerances if from reputable maker | Poor fit, out-of-tolerance dimensions common |

| Warranty & support | Manufacturer/dealer warranty and support | Limited warranty from supplier; documented support | No meaningful warranty or support |

| Price | Highest (reflects OEM quality) | Lower than OEM but justified by documentation | Lowest — usually too good to be true |

Source notes: Categories and attributes align with industry best practices and vendor documentation expectations (see references).

How to purchase with confidence: supplier checklist (excavator parts)

Before placing a bulk or expensive single-part order, perform this supplier due diligence:

- Confirm supplier identity: business license, physical address, and trade references.

- Check certifications: ISO 9001 (quality management), factory photos, and production process descriptions.

- Request sample shipments or a first small order for fitment verification.

- Ask for warranties, return policies, and spare parts support timelines.

- Verify logistics: confirm packaging, serial recording, and ability to provide batch traceability.

Brand advantages: Why consider SPARKLING MACHINERY for Hyundai excavator parts

When evaluating replacement excavator parts, SPARKLING MACHINERY positions itself as a supplier of Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA, including the NEW R160W9A R170W7 R170W7A R170W9 ZGAQ-03591 Hub. Strengths to consider:

- OEM compliance focus: Products are marketed to meet Hyundai OEM standards (part number correspondence such as ZGAQ-03591), making cross-referencing easier for buyers.

- Temperature and impact resistance: Claimed operating resilience from -30°C to 100°C suits wide operating environments, which is critical for undercarriage hubs.

- Cost-competitive sourcing: Chinese manufacturing can deliver competitive pricing while maintaining quality if proper QC and certifications are in place.

- Availability: For many operators, aftermarket or OEM-equivalent parts from reputable manufacturers reduce lead time compared with some OEM channels, improving machine uptime.

Note: Always request documentation (MTCs, QC reports, and warranty terms) from any aftermarket supplier before purchase to validate these advantages.

FAQ — Common questions about verifying Hyundai excavator parts

Q: How can I tell if a part marked ZGAQ-03591 is genuine?

A: Cross-check the part number in Hyundai's official parts catalog or with an authorized dealer, verify serial/lot numbers, inspect packaging and markings, and request MTCs or QC reports. Also perform dimensional checks and a fitment trial before extended use.

Q: Are high-quality aftermarket parts safe to use instead of Hyundai genuine parts?

A: High-quality, documented aftermarket parts can be a reliable alternative if they provide material certificates, traceability, warranty, and match OEM dimensions/tolerances. Always validate the supplier and perform pre-installation testing.

Q: What immediate red flags indicate counterfeit excavator parts?

A: Red flags include misspelled labels, inconsistent logos, poor packaging, missing or mismatched part numbers, lack of traceability, suspiciously low prices, and poor surface finish or dimensions out of tolerance.

Q: Should I refuse installation if my part fails verification?

A: Yes. Installing an unverified or suspected counterfeit part risks machine damage and safety. Return the part, document discrepancies, and source a verified replacement through authorized channels.

Q: Can I verify authenticity after installation?

A: Post-installation checks include measuring operational behavior, early wear inspection, and material testing if removal is possible. However, pre-install verification is strongly recommended to avoid risk.

Contact us / View Product — get verified parts now

If you need assistance verifying a part or want to purchase a verified ZGAQ-03591 Hub for Hyundai R160W9A/R170W7/R170W7A/R170W9, contact our sales and technical team. We provide part documentation, dimensional reports, and support for installation and warranty registration. Reach out to request product photos, MTCs, and sample fitment support.

References

- Hyundai Construction Equipment — official parts and service documentation. (Manufacturer parts catalogs are primary sources for OEM numbers and compatibility.)

- Association of Equipment Manufacturers (AEM) — publications and advisories on counterfeit heavy equipment parts and supply chain best practices.

- ISO 9001 — Quality management systems guidance for supplier verification and factory audits.

- ASTM material standards and general metallurgy references — for guidance on material certificates and testing.

Use the checklist and verification steps in this guide every time you buy excavator parts to reduce risk and ensure your equipment stays productive and safe.

Best excavator air conditioner parts manufacturers and supplier brands

Wholesale excavator left hand column manufacturer and supplier

Compatibility: VOE14558962 Brake Disc Fitment Guide for Volvo

The B2B Buyer’s Guide to Excavator Undercarriage Parts

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What is the lead time for receiving excavator parts?

Our typical lead time depends on the complexity and quantity of the order. For standard parts, delivery usually takes between 7 to 14 days. For custom orders, the lead time may vary, but we always strive to ensure timely delivery.

Excavator Spare Parts 6KG 424-64-15610 Hydraulic Valve for Komatsu WA380-3 WA420-3 WA450-3

SPARKLING MACHINERY NEW WA380 WA420 WA450 424-64-15610 Hydraulic Valve is a dedicated, high-precision control component exclusively engineered for KOMATSU WA380, WA420, and WA450 wheel loaders—equipment widely paired with excavators in construction, mining, and logistics for efficient material handling. As the core of the wheel loader’s hydraulic system, it precisely regulates hydraulic oil flow and pressure to control key functions (lift arm elevation, bucket tilting, steering), ensuring smooth, responsive operation during tasks like bulk material loading, stockpiling, and on-site material transfer. This function is vital for preventing hydraulic flow misdirection, maintaining operational accuracy, and avoiding unplanned downtime that disrupts coordinated excavator-loader workflows.

- Compatibility: It is compatible with several Komatsu models, including the WA380-3, WA420-3, WA450-3, WA470-3, and WF450 wheel loaders.

Excavator Spare Parts 9V battery XZFK-404 DIGITAL FLOW METER

SPARKLING MACHINERY NEW XZFK-404 Digital Flow Meter is a premium China-made fluid monitoring component designed for compatible construction machinery, hydraulic systems, and industrial fluid circuits—including those in excavators, loaders, and hydraulic power units. As the "fluid measurement guardian" of machinery systems, it accurately detects and displays real-time flow rates of hydraulic oil, coolant, or other industrial fluids, with a measurement range tailored to heavy-duty equipment needs. This enables operators and maintenance teams to monitor fluid circulation efficiency, identify abnormal flow (e.g., leaks, blockages), and optimize system performance—critical for preventing hydraulic component damage, reducing energy waste, and ensuring stable operation in construction, mining, and industrial scenarios.

Engineered to original equipment standards, it maintains high measurement accuracy even under harsh working conditions: high hydraulic pressure (up to 35 MPa), temperature fluctuations (-20°C to 80°C), vibration, and exposure to dust or hydraulic fluid contaminants. With a clear digital display (for easy readability) and a robust, corrosion-resistant housing, it resists environmental wear and ensures long-term reliability. Backed by strict quality verification, it guarantees precise fluid data to support proactive maintenance and minimize downtime caused by fluid system failures.

CATERPILLAR HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW GF950194 SOLENOID ASSY SPARKLING MACHINERY

SPARKLING MACHINERY NEW GF950194 Solenoid Assy is a core electromagnetic control component for Caterpillar excavators (heavy-duty construction/mining use). It converts electrical signals into mechanical motion to control fluid flow or mechanical switches, ensuring precise system operation.

Meeting Caterpillar OEM standards (GF950194), it resists -30°C to 100°C temps, electromagnetic interference, and wear, ensuring seamless compatibility and long-term reliable control performance.

Hyundai HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 GEAR-COUPLING SPARKLING MACHINERY

SPARKLING MACHINERY NEW R140LC-7 R140LC-7A R160LC7 XKAH-00360 Gear-Coupling is a core power transmission component for 3 Hyundai excavator models (construction/mining use). It connects and transmits torque between mechanical shafts, absorbing vibration and compensating for alignment deviations.

Meeting Hyundai OEM standards (XKAH-00360), it resists -30°C to 100°C temps, wear, and impact, guaranteeing seamless compatibility and long-term reliable transmission performance.

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879