Compatibility: VOE14558962 Brake Disc Fitment Guide for Volvo

- Fitment Overview and Vehicle Compatibility

- Which Volvo models are covered

- How to verify correct fitment

- Semantic keywords for fitment checks

- Technical Specifications and Performance Characteristics

- Product description and OEM compliance

- Key technical parameters

- Heat, friction and material behavior

- Installation, Inspection and Maintenance

- Preparation and safety checklist

- Step-by-step installation summary

- Routine inspection & service intervals

- Troubleshooting, Performance Comparisons and Safety Considerations

- Common fitment and performance issues

- Comparison: OEM-standard disc vs aftermarket alternatives

- Safety margin and operational guidance

- Brand Advantages: Why Choose SPARKLING MACHINERY VOE14558962

- Manufacturing and quality control highlights

- Value proposition for fleet managers

- Warranty and support

- FAQ

- Q: Can VOE14558962 fit older Volvo EW160/EW180 versions?

- Q: How do I measure minimum service thickness?

- Q: Is it necessary to machine (turn) the disc before reuse?

- Q: What bedding-in procedure is recommended?

- Authoritative references

Compatibility-focused overview: The VOE14558962 brake disc from SPARKLING MACHINERY is engineered to meet VOLVO OEM standards and fits the VOLVO EW160C, EW160D, EW160E, EW180C and EW180D wheeled excavator models. This fitment guide explains how to verify correct brake disc selection, interpret technical specifications such as friction surface dimensions, heat capacity and wea limits, perform installation and inspection, and troubleshoot common fitment and performance issues to ensure reliable braking on-road and off-road operations. Proper fitment directly influences wear patterns, so applying longevity tips for extending the life of Volvo excavator brake discs helps reduce replacement frequency.

Fitment Overview and Vehicle Compatibility

Which Volvo models are covered

The VOE14558962 brake disc is specifically manufactured for the following wheeled excavator models: EW160C, EW160D, EW160E, EW180C and EW180D. These models share similar brake system geometry and mounting interfaces, which allows this single OEM-numbered disc to be compatible across the range. Always verify the machine serial number and production year when cross-checking parts.

How to verify correct fitment

Before ordering or fitting a brake disc, verify these five items: 1) OEM part number (VOE14558962), 2) machine model and serial number, 3) disc nominal diameter and thickness, 4) hub bolt pattern and centering bore, and 5) caliper clearance and pad mating surface. Measuring the existing rotor dimensions (outer diameter, thickness, inner bore diameter) and comparing them with the replacement disc dimensions removes guesswork and prevents incorrect purchases.

Semantic keywords for fitment checks

Use and search for terms like brake rotor fitment, caliper mounting, wheel excavator brake compatibility, OEM part VOE14558962 and disc mount bore when confirming compatibility in catalogs or online parts systems.

Technical Specifications and Performance Characteristics

Product description and OEM compliance

SPARKLING MACHINERY NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 Disc Brake is a dedicated safety component for VOLVO EW160C/EW160D/EW160E/EW180C/EW180D wheeled excavators (used in road construction, municipal engineering, and material handling). As the core of the braking system, it provides stable stopping force to ensure safe on-road travel and off-road operation, preventing accidents during tasks like loading or navigating uneven terrain. Meeting VOLVO OEM standards (part no. VOE14558962), it endures high friction, -30°C to 90°C temperatures, and vibration. It resists wear and corrosion, ensuring long-term braking reliability for the five VOLVO models, with strict testing guaranteeing compatibility and safe performance.

Key technical parameters

Important specs you should confirm before purchase: disc outer diameter, nominal thickness, minimum service thickness (wear limit), bolt pattern (number and pitch), centering bore dimension, and material grade. The SPARKLING MACHINERY disc is designed for optimized heat dissipation and wear resistance consistent with heavy-duty excavator applications.

Heat, friction and material behavior

Excavator brake discs must withstand rapid heat build-up and cyclic thermal stress. This disc uses a cast steel formulation with controlled grain structure to improve thermal conductivity and reduce cracking risk. Terms such as ventilated disc, heat capacity, thermal cracking resistance and friction coefficient stability are relevant when comparing parts. For general background on braking physics, see the Brake disc (Wikipedia) entry which explains rotor dynamics and heat management in braking systems.

Installation, Inspection and Maintenance

Preparation and safety checklist

Before installation: park machine on level ground, apply park brake (if possible), chock wheels, and support axle/hub with rated jack stands. Wear PPE. Inspect caliper, pads, hub, bearings and studs for wear. Clean mating surfaces and check for oil, grease, or contamination that could reduce friction or hide cracks.

Step-by-step installation summary

1) Remove wheel and caliper, 2) unbolt old disc and clean hub flange, 3) check hub run-out and stud condition, 4) install new disc aligning bolt holes and center bore, 5) torque mounting bolts to Volvo-specified values in a star pattern, 6) reinstall caliper and pads, 7) perform dynamic brake bedding procedure per manufacturer guidance. Proper torque and correct centering avoid rotor distortion and uneven pad wear.

Routine inspection & service intervals

Inspect the brake disc and pads every 250-500 operating hours or during routine service intervals. Look for: minimum thickness exceedance, scoring, heat-checking (surface cracks), corrosion at inner edges, and abnormal pad wear. Measure disc run-out with a dial indicator; typical acceptable run-out is machine-specific — consult Volvo service documentation. For general vehicle brake system standards and inspection concepts see Brake (vehicle) - Wikipedia.

Troubleshooting, Performance Comparisons and Safety Considerations

Common fitment and performance issues

Typical problems include: rubbing due to incorrect disc thickness or wrong centering bore, squeal from glazing or pad contamination, pulsation from excessive run-out, and rapid wear caused by poor pad-disc pairing. Verify pad compound compatibility; some pads with aggressive friction can accelerate disc wear, while low-friction pads may reduce stopping power.

Comparison: OEM-standard disc vs aftermarket alternatives

Below is a concise comparison to help purchasing decisions.

| Feature | VOLVO OEM-standard (VOE14558962) | Generic aftermarket |

|---|---|---|

| Fitment accuracy | Exact OEM geometry and bolt pattern | Varies; risk of misalignment |

| Material & heat treatment | Controlled cast & heat treatment for excavator duty | Inconsistent; may lack thermal resilience |

| Testing & certifications | Factory-tested to match Volvo standards | Depends on vendor; often limited testing |

| Price | Moderate — value from fitment and longevity | Lower upfront cost but potential higher lifecycle cost |

Safety margin and operational guidance

Given heavy loads and demanding duty cycles for wheeled excavators, prioritize discs that maintain braking torque and dissipate heat without cracking or warping. Maintain a safety margin above the service wear limit. Replace discs in pairs (both sides of an axle) to ensure balanced braking unless the opposite disc is near-new and measured within tolerance limits.

Brand Advantages: Why Choose SPARKLING MACHINERY VOE14558962

Manufacturing and quality control highlights

SPARKLING MACHINERY produces parts to meet or exceed OEM dimensions and material specifications. Their VOE14558962 discs undergo dimensional checks, dynamic balancing and hardness tests to ensure consistent friction surface performance and reduced vibration. Compliance with quality management practices (e.g., ISO-based processes) improves traceability and reliability over commodity discs.

Value proposition for fleet managers

Choosing a tested OEM-standard disc reduces unexpected downtime, lowers maintenance complexity (one correct spare across multiple models), and improves overall safety. Reduced replacement frequency and predictable wear patterns cut total cost of ownership for busy fleets operating in municipal and road construction environments.

Warranty and support

SPARKLING MACHINERY typically offers warranty coverage and technical support for fitment and installation. Documented compatibility with Volvo models and supplier testing records help service teams justify replacements and maintain equipment uptime.

FAQ

Q: Can VOE14558962 fit older Volvo EW160/EW180 versions?

A: It fits the specified EW160C/D/E and EW180C/D models. For older or non-C/D/E variants, always confirm the serial number and compare rotor dimensions; some earlier chassis revisions may use different mounting interfaces.

Q: How do I measure minimum service thickness?

A: Measure rotor thickness with a micrometer at multiple points near the friction surface (away from chamfers). Compare the readings to the minimum thickness stamped or specified by the manufacturer. Replace the disc when thickness approaches or falls below that limit.

Q: Is it necessary to machine (turn) the disc before reuse?

A: Light machining can restore a smooth surface if the disc is above minimum thickness and free of deep cracks. However, machining reduces thickness and the disc must remain above the minimum service limit. For excavator applications, replacement is often preferred over turning due to heavy-duty thermal and loading history.

Q: What bedding-in procedure is recommended?

A: Perform progressive braking with moderate speed reductions and repeated cycles to gradually raise disc and pad temperatures, allowing friction layers to stabilize. Avoid abrupt heavy braking during the first operating hours after installation.

Need assistance selecting the right part or verifying fitment? Contact our sales and technical team to check machine serial numbers and order the correct VOE14558962 disc. View or purchase the product: VOLVO EXCAVATOR PARTS MADE IN CHINA NEW EW160C EW160D EW160E EW180C EW180D VOE14558962 DISC BRAKE SPARKLING MACHINERY.

Authoritative references

- Brake disc — Wikipedia

- Brake (vehicle) — Wikipedia

- ISO 9001 — Quality Management (ISO)

- Volvo Construction Equipment — Official Site

For product quotations, compatibility checks or technical drawings, please contact our sales team or view the product page to request a datasheet and OEM compliance documentation.

Compatibility Guide: Bearings for R210W-9 and R200W7A

Lifecycle Cost Considerations: LS52S00013F1 Low Pressure Sensor

Understanding Wear Patterns on Excavator Hubs

Benefits of VOE14558962 Brake Disc for Volvo EW160/EW180

faq

Can I get technical support for installing your parts?

Absolutely. We provide technical support and guidance for the installation and maintenance of our parts. Our team is available to assist you with any questions or concerns to ensure proper installation and optimal performance.

Are your products covered by a warranty?

-

Yes, all of our excavator parts come with a warranty to ensure quality and reliability. The warranty period may vary depending on the type of part. Please contact us for detailed warranty terms for specific products.

-

Do you offer customized parts?

-

Yes, we offer tailored solutions to meet specific customer requirements. Whether you need custom dimensions or specialized features, we can design and produce parts that perfectly match your excavator’s needs.

-

How do you ensure the quality of your parts?

We follow strict quality control procedures throughout the manufacturing process. Our parts are tested for durability, performance, and precision to ensure they meet industry standards and exceed customer expectations.

What types of excavator parts do you manufacture?

We manufacture a wide range of excavator parts, including hydraulic components, undercarriage parts, engine parts, wear parts, and more. Our products are designed to fit a variety of excavator models and are built to meet the highest quality standards.

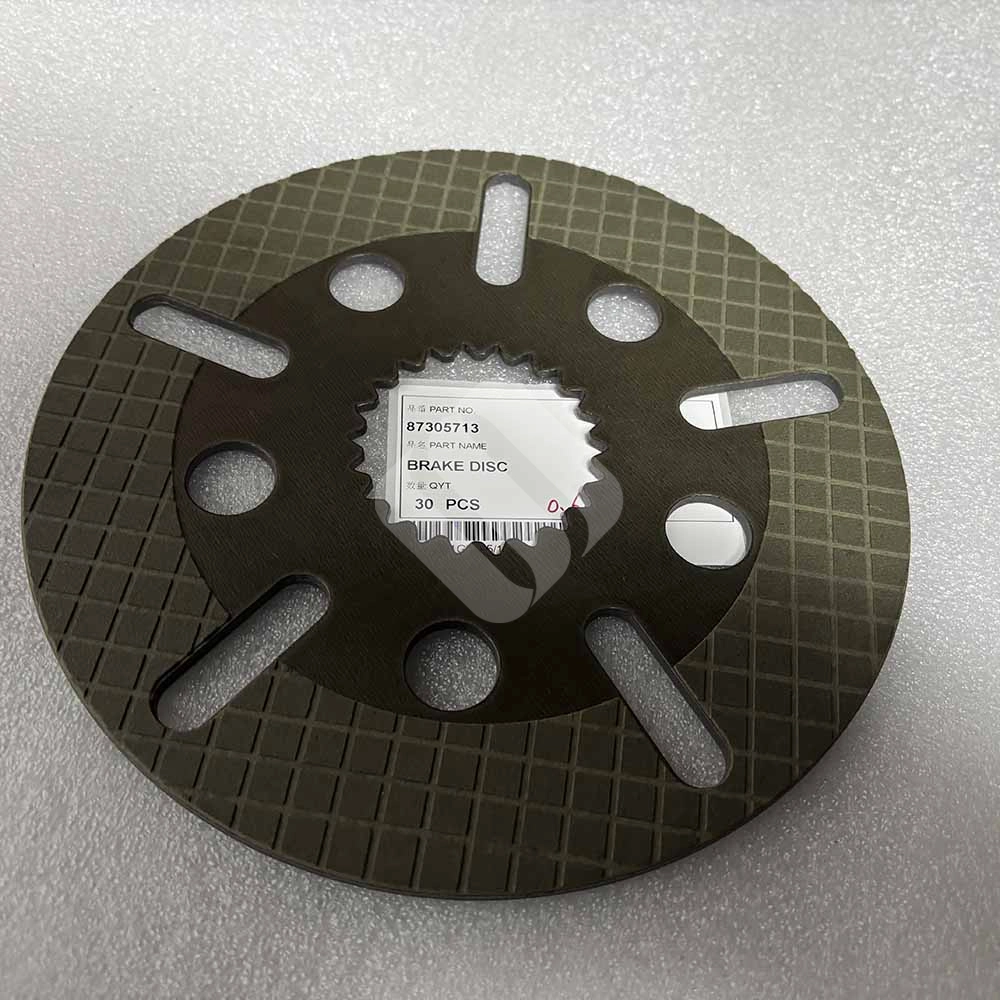

VOLVO HIGH-QUALITY EXCAVATOR PARTS MADE IN CHINA NEW B110B B100B LB90.B B90B B95B 87305713 BRAKE DISC SPARKLING MACHINERY

SPARKLING MACHINERY NEW B110B B100B LB90.B B90B B95B 87305713 Brake Disc is a core braking component for Volvo B110B/B100B/LB90.B/B90B/B95B excavators (heavy-duty construction/mining use). It works with brake pads to generate friction, ensuring reliable stopping and operational safety.

Meeting Volvo OEM standards (87305713), it resists -30°C to 300°C temps, wear, and thermal deformation, ensuring seamless compatibility and long-term reliable braking performance.

New Holland Backhoe Loaders 87305713 83959970 47123297 Brake Disc

87305713 is a specific industrial part number for a Brake Disc (or Friction Plate) used in agricultural and construction machinery, primarily manufactured by New Holland.

1.This friction disc is designed for oil-immersed (wet) braking systems. It is commonly found in:

New Holland Backhoe Loaders: Models including B90B, B100B, B110B, B115B, LB75, LB90, LB110, and LB115.

Ford Tractors: Series 550, 555, and 655.

Case IH: Certain models sharing the same drivetrain components

2. Technical Specifications

Outside Diameter (OD): ~204.75 mm

Inside Diameter (ID): ~55.88 mm (spline area)

Thickness: 4.8 mm

Teeth Count: 22 Teeth

Material: Paper-based friction material with a waffle-groove pattern for oil circulation and cooling

3. Cross-Reference Numbers

This part is often interchangeable with the following OEM and aftermarket numbers:

CNH: 83959970, 47123297

Ford/NH Original: E6NN2A097BB

Hyundai Wheel Loaders HL730-9 HL730-9A HL730-9S ZGAQ-03450 0501.323.355 DISC-INNER CLUTCH CHINA MADE

Part numbers 0501.323.355 (a ZF part number) and ZGAQ-03450 (a Hyundai part number) both refer to a Friction Disc used in the brake or clutch assembly of heavy machinery transmissions and axles.

This component is an inner clutch or brake friction plate/disc. It is a critical wear item within the drivetrain assembly (likely a ZF axle or transmission) responsible for creating the necessary friction to engage clutches or apply brakes in heavy equipment.

Compatible Equipment

This friction disc is commonly used in Hyundai wheel loaders and other construction equipment that utilize compatible ZF axles:

Hyundai Wheel Loaders: HL730-9, HL730-9A, HL730-9S, HL730TM-9A.

Other Compatible Equipment: Various backhoe loaders, including certain models by John Deere (e.g., 310, 315, 210K, 310SJ, 325K)

Part Numbers: 0501.323.355, 0501323355, ZGAQ-03450, ZGAQ03450, AT339543, 482-6743, VOE 15071853, S06/42932

ZTAM-00615 Support Kit Compatible with Hyundai R140W-7 & R140W-7A Wheel Excavators

ZTAM-00615 is an OEM-compatible support kit for Hyundai R140W-7/R140W-7A excavators. It provides essential structural reinforcement and vibration damping for key components, ensuring reliable performance under heavy loads and harsh working conditions in construction and engineering applications.

Key Features

· OEM direct‑fit design: Exact matching of mounting positions, hole spacing, and geometric dimensions for Hyundai R140W‑7 / R140W‑7A — plug‑and‑play without modification.

· High‑strength structural support: Heavy‑duty steel construction with reinforced stress points for excellent load capacity and impact resistance.

· Stable & durable: Anti‑wear, anti‑deformation, and anti‑corrosion surface treatment for long service life in harsh environments.

Compatible Models: Hyundai Wheel Excavators R140W-7, R140W-7A

Sparkling Machinery Co.,Ltd

foreverlucia1

Whatsapp: +8613609010879